Product Description

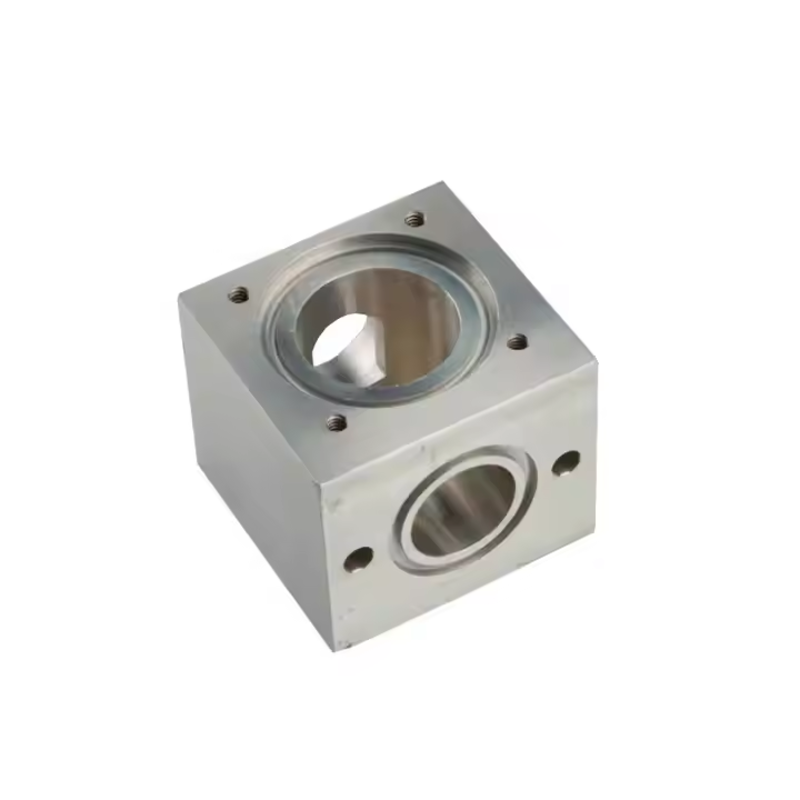

CNC Moto Accessories are precision-engineered for motorcycle enthusiasts who demand top-tier performance and design. Manufactured using advanced CNC machining technology, these accessories are crafted from high-quality materials for durability and strength. The range includes custom parts such as foot pegs, handlebars, grips, and mirrors, all designed to enhance both the aesthetics and functionality of your bike. Each accessory is tailored to fit specific models, ensuring a perfect fit and seamless integration. With a focus on precision, performance, and style, our CNC Moto Accessories elevate the riding experience to a new level.

Product parameters

| List | Details |

|---|---|

| Product name | Stainless Steel Industrial Equipment Cnc Moto Accessories |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Material | Aluminum, copper, brass, stainless steel, iron, alloy, zinc etc. |

| Process | CNC Machining |

| Surface treatment | Anodizing,Galvanized,laser engraving,polishing,Powder coating, |

| Service | OEM ODM CNC Drilling Milling Machining Service |

| Application | Industrial Equipment |

| Equipment | CNC Machining Centres |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

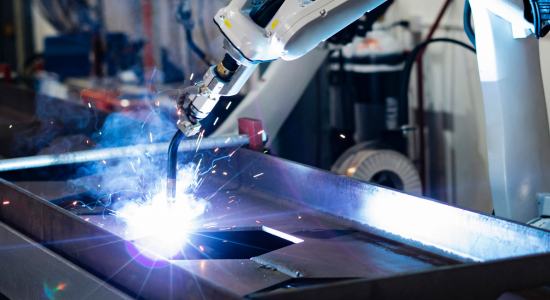

Milling & Drilling

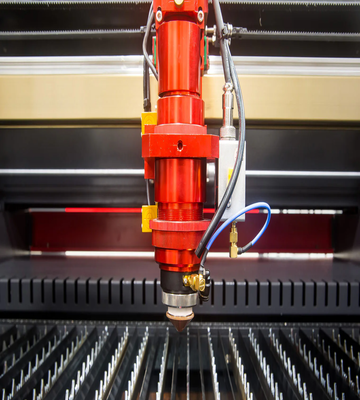

Laser Cutting

Turning

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

QC process for CNC Moto Accessories ensures the highest standards of quality and performance. Each accessory undergoes meticulous inspection using advanced measurement tools to verify dimensional accuracy and fit. We conduct thorough material checks to ensure durability and resistance to wear. After machining, parts are tested for functionality, surface finish, and aesthetic quality. Automated quality control systems track the production process, reducing errors and ensuring consistency. This rigorous approach guarantees that every CNC Moto Accessory meets the exact specifications and enhances the performance of your motorcycle.

Processing capability

CNC Moto Accessories are manufactured using state-of-the-art CNC machining technology, ensuring high precision and quality for every part. We specialize in producing custom motorcycle components with tight tolerances, ensuring perfect fits and enhanced performance. Using multi-axis CNC machines, we can craft complex geometries and intricate designs, including foot pegs, handlebar grips, levers, and mirrors, with exceptional accuracy.

We work with a variety of materials such as aluminum, titanium, stainless steel, and high-performance plastics, providing durability and lightweight solutions tailored to meet the specific needs of riders. Our CNC machining process allows for both small-batch and large-scale production, maintaining consistent quality and efficiency throughout.

Additional processes

With advanced CAD/CAM software, we optimize machining strategies to achieve the best surface finishes, reduce cycle times, and ensure high-quality results. Post-processing options such as anodizing, powder coating, and polishing enhance the aesthetics and durability of each accessory. This comprehensive approach guarantees precision, performance, and style, making our CNC Moto Accessories the perfect choice for motorcycle enthusiasts seeking superior quality and design.