Product Description

Our reputation for reliability and precision has led many customers to return to us time and again for their machining needs. This trust has enabled us to build long-term partnerships based on our consistent delivery of superior products and services. We take pride in our ability to meet even the most complex and demanding specifications, ensuring that each project is completed on time, within budget, and to the highest quality standards.

At the core of our business philosophy is a relentless drive for continuous improvement, innovation, and the pursuit of excellence in everything we do. Whether it's investing in state-of-the-art machinery, implementing advanced manufacturing techniques, or training our skilled workforce, we are constantly seeking ways to enhance our capabilities and better serve our clients. Our dedication to quality, combined with a customer-centric approach, allows us to provide tailored solutions that not only meet but exceed expectations.

Product parameters

| processing | CNC turning, CNC milling, Drilling, Grinding, Spinning, Wire-EDM Cutting, Stamping, Laser Cutting, Bending, Die Casting, Extrusion, Injection Molding |

| Material | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Titanium: Grade F1-F5 | |

| Surface treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| quality assurance | ISO 9001:2015, SGS,16949,ROHS |

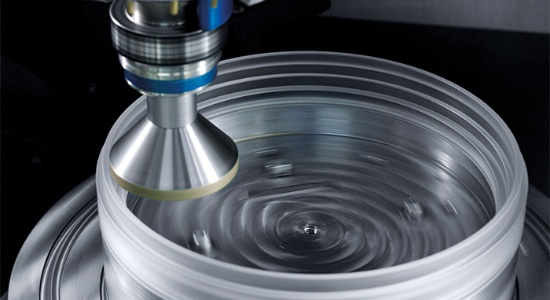

| Tolerant | +/-0.002~+/-0.005mm |

| Surface roughness | Min Ra 0.1~3.2 |

Custom Process

1. Product Design

2. CNC Turning

3. CNC Center

4. Quality Test

5. Package

6. Transportation

7. Use and Feedback

8. Win-win Cooperation

Process Type

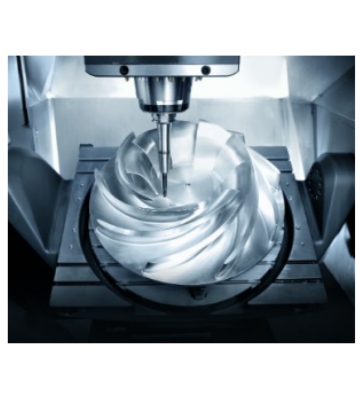

Process type five-axis machining

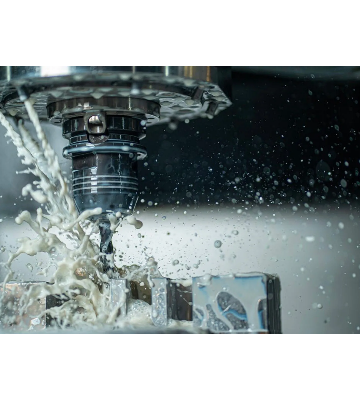

CNC Milling

CNC Machining

Material

Stainless Steel

Aluminu Alloy

Brass

Contact Us

Quality Control

- Consistent calibration and inspection tool

- Optional XRF analysis report

- Well-equipped inspection department

- Materials inspection by IQC

- FQC will check the products

- 100% inspected by OQC before shipping

- Designated area for nonconforming products

- Root cause analysis of unqualified

Additional processes

Abrasive Jet Machining (AJM)

Applications: Commonly used for cleaning hard-to-reach areas, deburring sharp edges, or cutting fragile or soft materials like plastics or ceramics.

Key Benefits: Capable of producing fine finishes, good for fragile materials, and can be used for very intricate parts.

Ultrasonic Machining (USM)

· Applications: Commonly used for machining brittle materials like ceramics, glass, and hard metals.

· Key Benefits: Produces no heat, excellent for brittle materials, and allows for fine detail machining with minimal tool wear.