Product Description

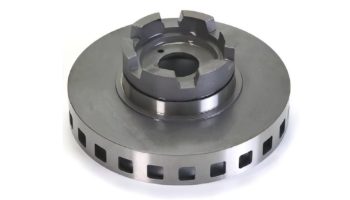

In the realm of manufacturing, precision is paramount. From aerospace and automotive to medical and beyond, industries rely on precision parts for optimal performance and reliability. When it comes to CNC (Computer Numerical Control) machining, finding a trusted service provider that specializes in precision parts is essential. At ERIK, we take pride in offering exceptional CNC machining services for precision parts, delivering superior quality and accuracy to our valued clients.

Product parameters

| processing | CNC turning, CNC milling, Drilling, Grinding, Spinning, Wire-EDM Cutting, Stamping, Laser Cutting, Bending, Die Casting, Extrusion, Injection Molding |

| Material | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Titanium: Grade F1-F5 | |

| Surface treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. |

| quality assurance | ISO 9001:2015, SGS,16949,ROHS |

| Tolerant | +/-0.002~+/-0.005mm |

| Surface roughness | Min Ra 0.1~3.2 |

Custom Process

1. Customer inquiry

2.Send drawing/sample

3. Mold making

4. Machine processing

5. Quality Control

6. Packing

7. Transportation

8. After-sale support

Process Type

Deburring

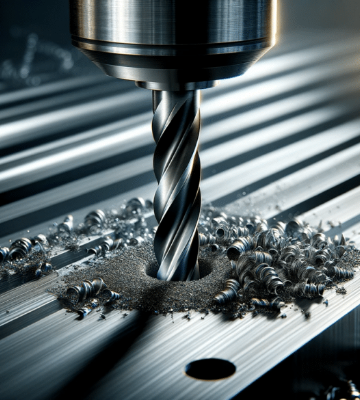

Drilling

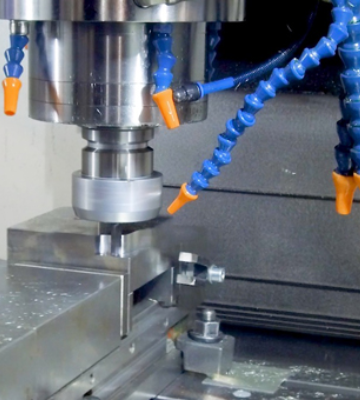

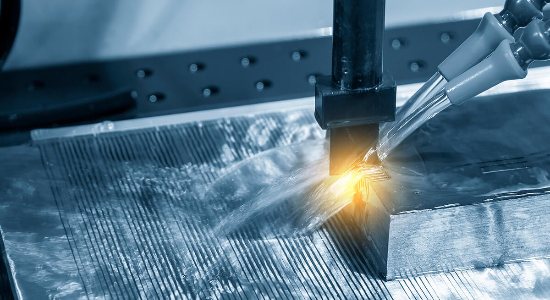

CNC Machining

Material

Aluminum Alloy

Zinc Alloy

Alloy Steel

Stainless Steel

Quality Control

The Coordinate Measuring Machine (CMM) is an invaluable tool in manufacturing and quality control due to its high precision, repeatability, efficiency, and versatility. It significantly enhances the quality control process by providing fast, accurate, and automated measurements across a wide range of part sizes and geometries. CMMs reduce human error, scrap, and rework, while improving productivity and providing traceability for compliance with industry standards. This makes them an essential tool in industries that demand the highest levels of part accuracy and quality, from aerospace and automotive to electronics and medical devices.

Processing capability

Our CNC machining service is backed by a team of highly skilled and experienced professionals who are dedicated to delivering excellence. Our engineers, machinists, and technicians have a deep understanding of CNC machining principles and techniques. They leverage their expertise to optimize the machining process, select the most appropriate cutting tools and techniques, and ensure that every operation is executed with precision and accuracy. With their meticulous attention to detail and commitment to quality, our team guarantees that your precision parts are machined to perfection.

Additional processes

EDM (Electrical Discharge Machining)

· Wire EDM: Used for cutting complex shapes, intricate details, or hard-to-machine materials like tool steel and carbide. The wire acts as an electrode, eroding material from the workpiece in a controlled manner.

· Sinker EDM: Also known as plunge EDM, this process uses a shaped electrode to create cavities, pockets, or other complex geometries within hard metals, making it ideal for tool and die making, mold creation, or precision part manufacturing.

Advantage: EDM is ideal for producing complex shapes and fine features with high accuracy, especially in materials that are difficult to machine with conventional methods.