Product Description

Our company, ERIK, has years of extensive experience in the precision machining of robotic components. We specialize in creating high-quality, custom-engineered parts that meet the exacting standards of the robotics industry. Whether you're in need of components for industrial automation, collaborative robots, or specialized machinery, we are committed to delivering products that combine cutting-edge technology with superior craftsmanship.

We pride ourselves on our ability to maintain strict quality control throughout the manufacturing process, ensuring that every component performs flawlessly in even the most demanding environments. From prototyping to full-scale production, our team works with precision and dedication to ensure that your projects are completed on time and to the highest specifications.

At ERIK, we understand that each project is unique. That’s why we offer fully customized solutions, collaborating with you every step of the way to meet your specific needs. Our advanced machining capabilities, combined with our in-depth industry knowledge, allow us to deliver parts that are not only precise but also durable, ensuring long-lasting performance and reliability.

We invite you to reach out to us and explore how our expertise in precision machining can elevate the quality and performance of your robotic systems. Let us help bring your vision to life with expertly crafted components that give you a competitive edge in the market.

Product parameters

| Product Name | Custom precision aluminum/metal/zinc alloy cnc machining service |

| Material | Aluminum,Hardened Metals, Precious Metals, Zinc alloy |

| Weight | / |

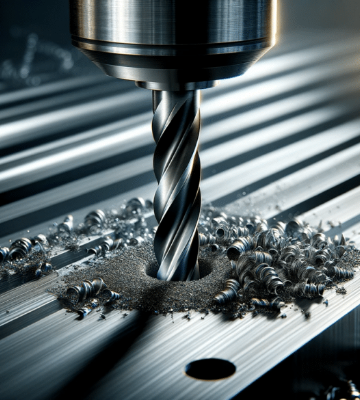

| Tolerance | 0.005mm~0.1mm |

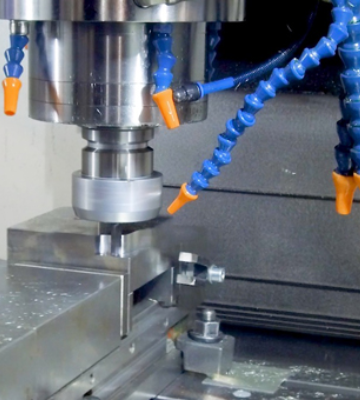

| Equipment | CNC Machining center, CNC Lathe, Turning machine, Milling machine, Drilling machine, Internal and external grinding machine, Cylindrical grinding machine, Tapping drilling machine, Wire cutting machine, polishing machine etc. |

| Surface treatment | Anodizing, sandblasting,Powder Coating, zinc/chrome/nickel/silver/gold Plating, Polish, Nitriding, Blacking, Painting, Heat treatment etc |

| MOQ | 100pcs, according to your drawings |

| QC System | 100% inspection before shipment, product OK rate 99.8% |

| Drawing | Provide by customer, or design according as the sample |

| Drawing format | Pro/E, AutoCAD, Solidworks, CAXA, UG, CAD, CAM, CAE, STP, IGES, etc. |

| Payment term | T/T, Erik pay, West Union,etc |

Custom Process

1. Customer inquiry

2.Send drawing/sample

3. Mold making

4. Machine processing

5. Quality Control

6. Packing

7. Transportation

8. After-sale support

Process Type

CNC Machining

Die Casting

Drilling

Quality Control

Quality is at the core of our CNC machining service. We adhere to rigorous quality control processes throughout the entire manufacturing process. From material selection to final inspection, we maintain strict adherence to industry standards and specifications. Our quality assurance measures include comprehensive inspections, dimensional accuracy checks, and surface finish assessments. By upholding the highest standards of quality, we ensure that your precision parts meet or exceed your expectations.

Our commitment to quality doesn’t stop at the inspection stage — it is embedded in every phase of production. We use advanced inspection tools and techniques, including CMM (Coordinate Measuring Machines), laser measurement systems, and high-resolution microscopes, to guarantee that every part is fabricated to perfection. Our skilled quality control team conducts thorough checks at multiple points during production, ensuring that even the smallest detail is flawless.

With a dedicated focus on maintaining consistent quality, we ensure that your parts are not only precise but also durable and reliable. Our adherence to international quality standards, such as ISO 9001, and our strong commitment to continuous improvement, guarantee that your CNC machined components will meet the highest levels of performance and longevity in any application.

Processing capability

At ERIK, we pride ourselves on our extensive processing capabilities, which allow us to tackle a wide range of complex and challenging machining projects. With state-of-the-art CNC machines and advanced machining technologies, we can handle everything from simple parts to intricate, high-precision components for robotics, automation, and other demanding industries.

Our diverse range of machining services includes turning, milling, drilling, grinding, and EDM (Electrical Discharge Machining), all carried out with the highest degree of precision. Whether you're working with metals, plastics, or other specialized materials, our versatile capabilities ensure that we can produce parts to your exact specifications, no matter the complexity.

With a team of experienced engineers and technicians, we work closely with our clients to optimize designs, improve manufacturability, and streamline production processes. Our ability to offer custom machining solutions for both simple and highly complex parts makes us a trusted partner in a wide variety of industries, including robotics, aerospace, automotive, and medical technology.

At ERIK, we continuously invest in the latest machinery and tools, ensuring that our processing capabilities evolve alongside technological advancements. This commitment allows us to stay ahead of industry trends, enabling us to offer cutting-edge solutions that meet the most demanding customer requirements.

Additional processes

Tumbling and Vibratory Finishing

· Tumbling: A process where parts are placed in a rotating drum with abrasives or polishing media. This process is ideal for deburring, polishing, and rounding edges of small parts.

· Vibratory Finishing: Similar to tumbling, but instead of rotation, parts are vibrated with media in a bowl or trough. This is used for deburring and polishing parts in bulk, especially small and delicate components.

Advantage: Ideal for deburring, polishing, and surface preparation for high-precision parts with intricate geometries or sharp edges.