Product Description

CastDrive Rotor is crafted from high-quality materials to ensure exceptional durability, strength, and enhanced performance. Designed for efficiency, it minimizes long-term wear and tear, making it a reliable choice for demanding applications across various industries.

Product parameters

| Product Name | Communication Equipments |

| Application | All areas |

| Material | ADC12 |

| Process | die asting /CNC machining |

| Surface Treatment | The earthquake light |

| Application | All areas |

| Color | As Customer Request |

| Dimension | Customized |

| Packaging | EPE foam/Anti-Rust Paper/Stretch Film/Plastic bag +Carton |

| Drawing Format | PRO/E, Auto CAD, Solid Works , UG, CAD/CAM/CAE, PDF |

| Lead Time | 15-20days |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

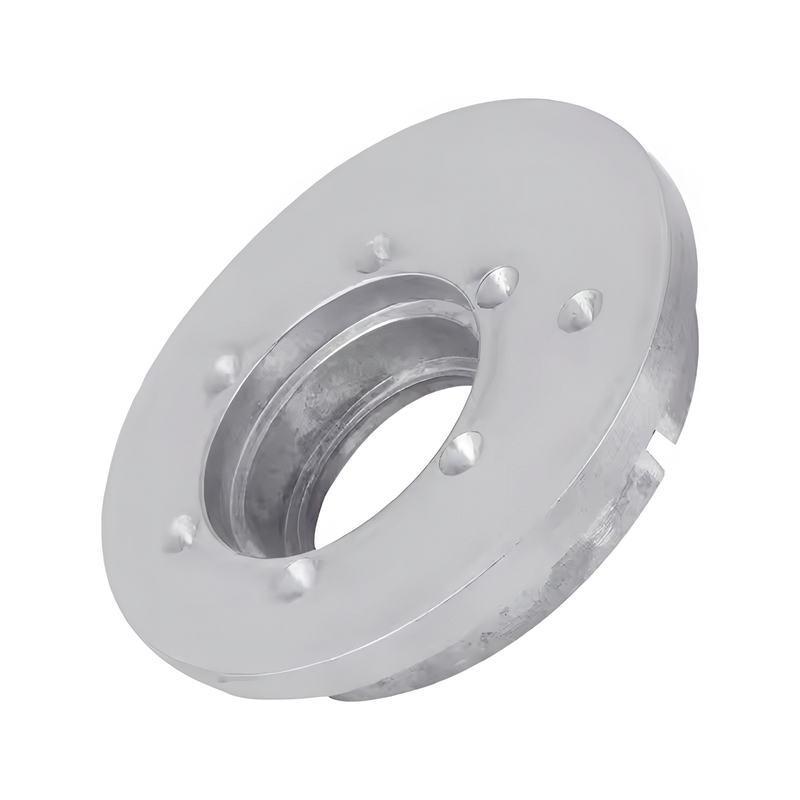

Rotor Housing

Used in pump systems or machinery requiring strong rotational support.

Reason: The shape allows assembly with other parts and is well-suited for high-pressure pumps or machinery requiring stability.

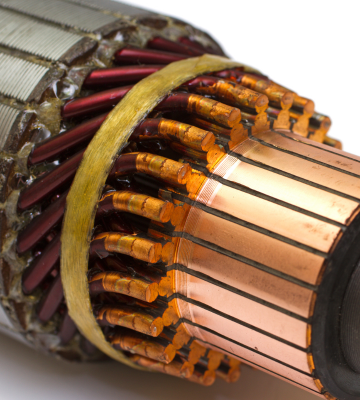

Gear Housing

Serves as a structural component for installing gears in power transmission systems.

Reason: The design provides durability against high forces, making it ideal for automotive or industrial machinery applications.

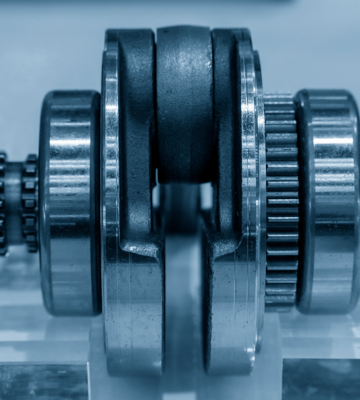

Brake Drum Component

Used in vehicle braking systems.

Reason: Its design supports axle installation and is made from materials capable of withstanding heat and friction effectively.

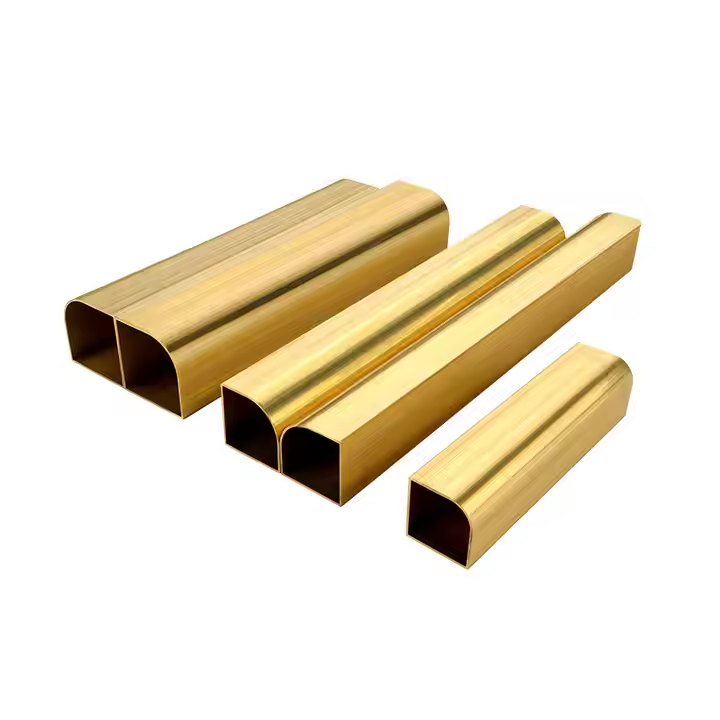

Material

Brass

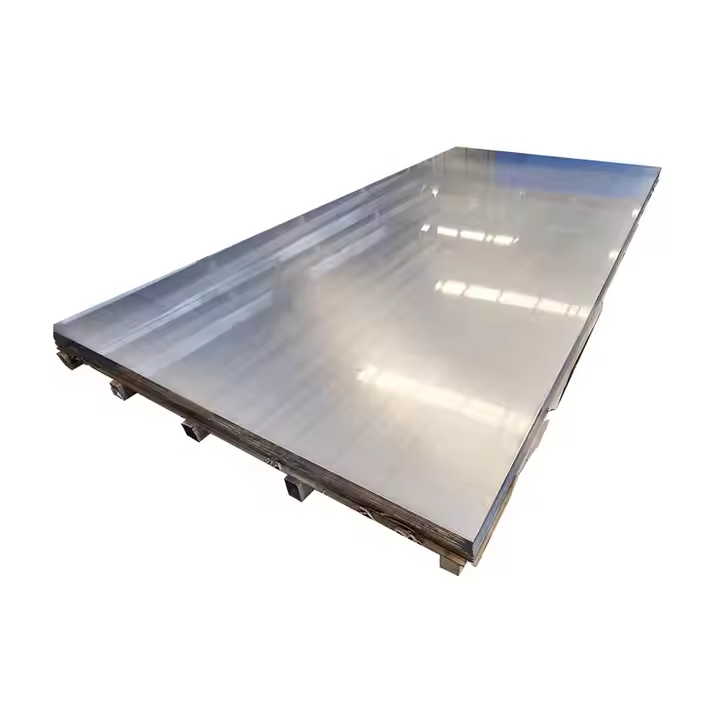

Aluminum

Quality Control

The quality control of the CastDrive Rotor focuses on ensuring precision, durability, and performance. Each rotor undergoes rigorous inspections to verify dimensional accuracy, surface finish, and material integrity. Advanced testing methods, such as X-ray inspection and hardness testing, are applied to detect internal defects and confirm structural reliability. The production process is monitored to maintain consistency, while the final product is evaluated for functionality under real-world conditions, ensuring it meets industry standards and customer requirements.

Processing capability

The CastDrive Rotor is crafted using precision casting and advanced CNC machining to achieve complex geometries and tight tolerances. It supports a wide range of alloy materials and offers customizable designs to meet specific industrial needs. Surface treatments such as polishing or coating are available to enhance corrosion resistance and ensure long-lasting performance in demanding environments.

Additional processes

The CastDrive Rotor undergoes additional processes to enhance its quality and performance, including heat treatment for improved strength and durability, surface finishing for smoother operation, and protective coating to resist corrosion. These processes ensure the rotor meets stringent industry standards and performs reliably in demanding applications.