Product Description

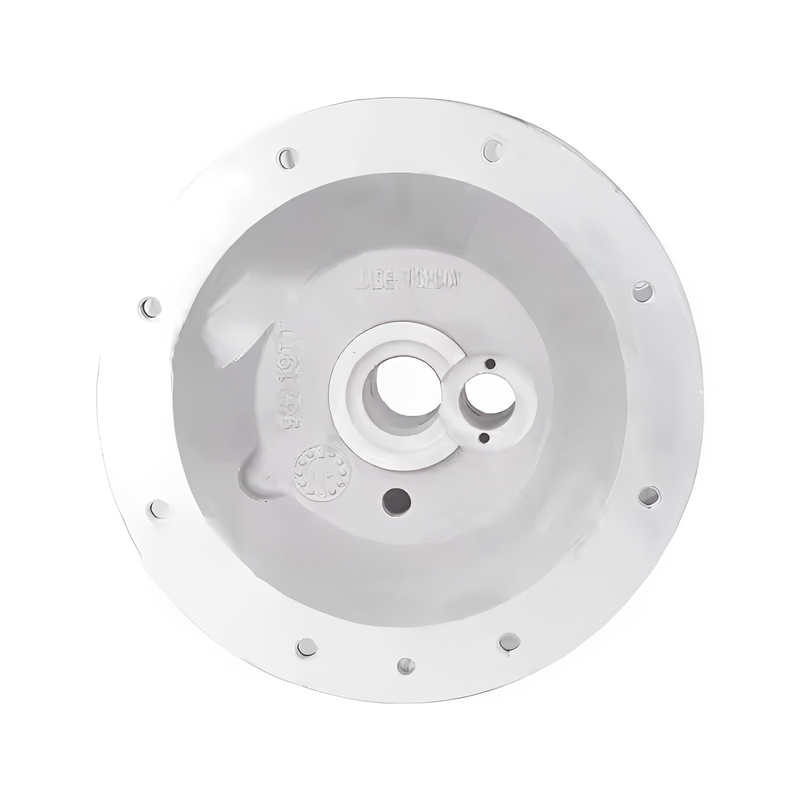

The Booster pump ensures consistent water pressure for both residential and industrial use. Designed for high performance and durability, it provides efficient water flow, easy operation, and low maintenance, making it reliable for long-term use in various applications.

Product parameters

| Product Name | Booster pump |

| Material | A356 |

| Process | Casting /Machining(if Need) |

| Surface Treatment | sand blasting/oxidation |

| Application | All areas |

| Color | As Customer Request |

| Dimension | Customized |

| Packaging | EPE foam/Anti-Rust Paper/Stretch Film/Plastic bag +Carton |

| Drawing Format | PRO/E, Auto CAD, Solid Works , UG, CAD/CAM/CAE, PDF |

| Lead Time | 15-20days |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

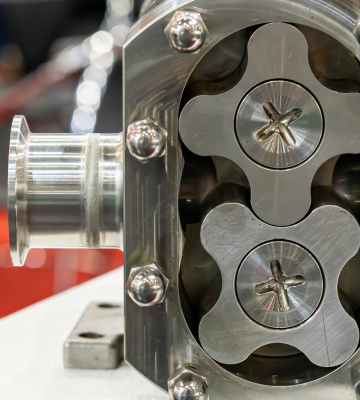

High-Pressure Water Pump Gearbox:

- Utilized as the main structure to support the gearbox and power transmission shaft.

- Reason: Durable material ensures stability in power transmission and prevents wear under high water pressure.

Wind Turbine Rotor Hub:

- Supports the turbine blades.

- Reason: Requires materials that can handle wind torque and ensure high precision.

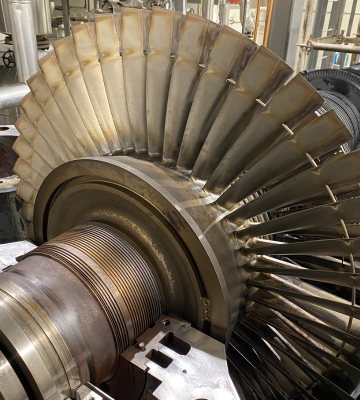

Industrial Metal Cutting Machine:

- Used as the base for the rotor system in cutting operations.

- Reason: A stable structure reduces vibrations, enhancing cutting accuracy.

Material

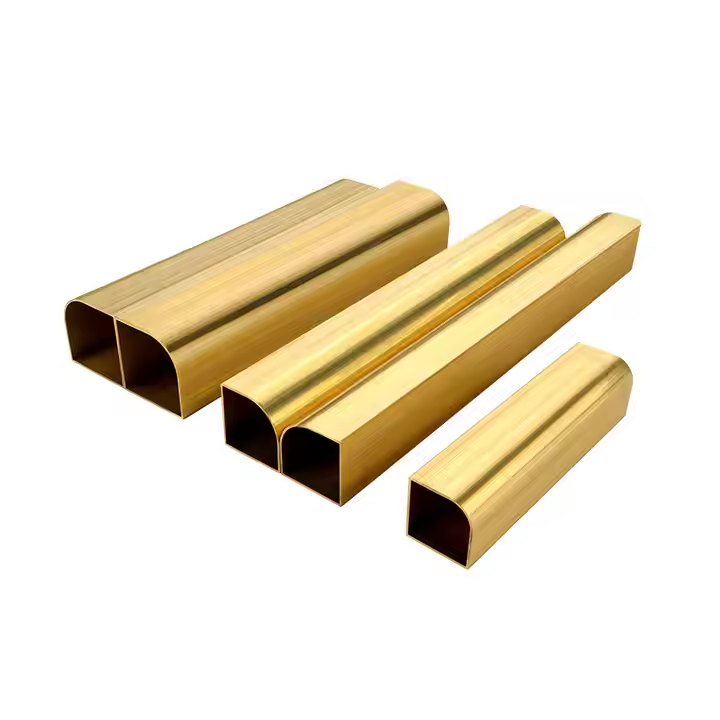

Brass

Aluminum

Quality Control

The quality control of the Booster pump involves thorough testing to ensure reliable performance and durability. Each unit undergoes strict inspections to verify pressure efficiency, leak resistance, and motor functionality. The pump is tested under various operating conditions to ensure consistent water flow and optimal performance. Additionally, all materials and components are checked for quality, and the final product is assessed for longevity, noise levels, and energy efficiency to meet industry standards and customer expectations.

Processing capability

The processing capability of the Booster pump includes advanced manufacturing techniques such as precision casting and machining to ensure high-quality components and tight tolerances. It supports a variety of materials for durability and resistance to wear, while assembly processes are optimized for seamless integration of motor and pump components. The pump is designed to accommodate various pressure requirements and configurations, making it suitable for diverse residential and industrial applications. Additionally, customizations for size, power, and performance are available to meet specific customer needs.

Additional processes

Additional processes for the Booster pump include heat treatment to enhance material strength and durability, as well as surface coating to prevent corrosion and ensure longer service life. Each unit undergoes dynamic balancing to minimize vibration and noise during operation. Quality checks are performed throughout the assembly process to ensure precise fitting and optimal performance. The final product is tested under different pressure conditions to ensure reliable, efficient operation in a variety of environments.