Product Description

At ERIK, we specialize in delivering precision stamping components across a wide range of industries, including robotics, automotive, electronics, and more. With years of experience and a strong technical team, we are capable of handling both simple and highly complex custom stamping projects. Our commitment to quality means every product is subjected to rigorous quality control to ensure it meets the highest standards before reaching you.

We understand that every customer’s needs are unique, and that’s why our design and production capabilities are flexible and adaptable. Whether it’s material selection, production processes, or delivery timelines, ERIK is dedicated to providing tailor-made solutions that perfectly align with your requirements. Our global supply chain and extensive partnerships also allow us to offer cost-effective options without compromising on quality.

When you choose ERIK, you are not just selecting a supplier – you are gaining a reliable partner who will support your business growth and help you succeed. We pride ourselves on our customer-first approach, always ensuring that your needs are met with professionalism, expertise, and precision.

Product parameters

| SHEET METAL FABRICATION | |

|---|---|

| Available Materials | Aluminum,steel,stainless Steel,brass,copper,iron, Etc |

| Surface treatment | All kinds of surface treatments are available, polishing, zinc plating, nickel plating, chrome plating, powder coating, and phosphate coating. |

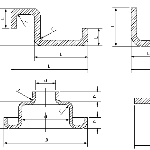

| Processings | Laser Cutting, Precision Stamping, CNC Bending, CNC Milling, CNC Turning, Threading, Riveting, Drilling, CNC Punching, Die Casting, Laser Welding, etc. |

| Tolerance | DIN ISO 2768, 100% QC quality inspection before delivery, can provide quality inspection form. |

| Drawing Accepted | IGS、STP、X_T、DXF、DWG、Pro/E、PDF |

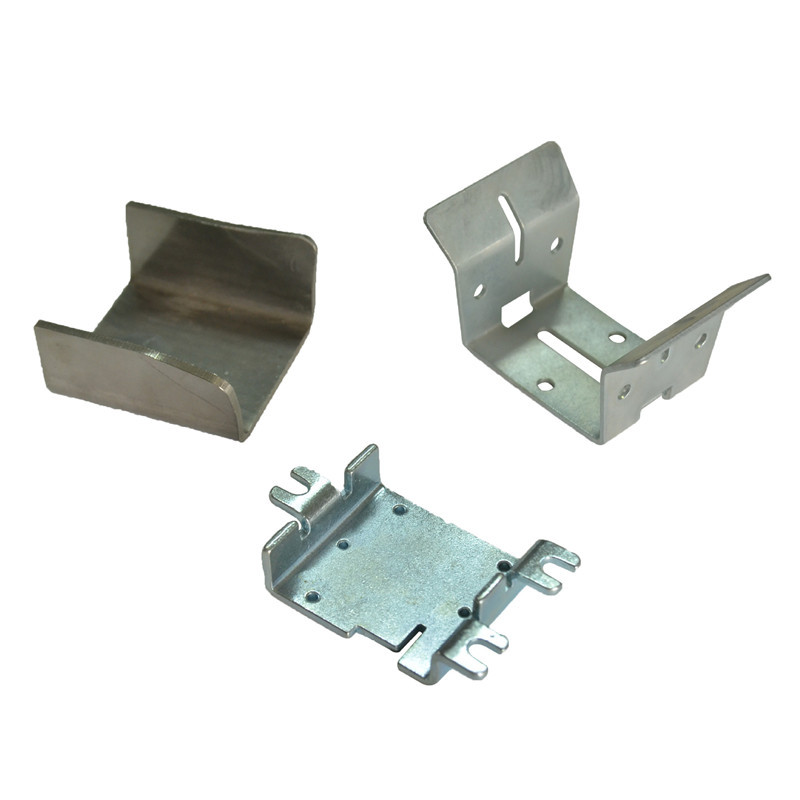

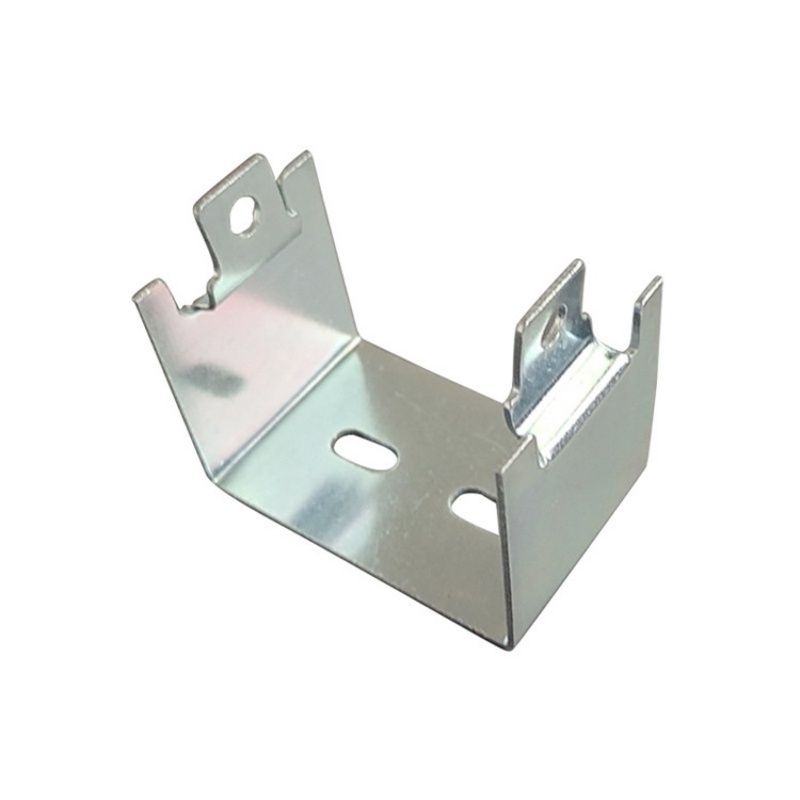

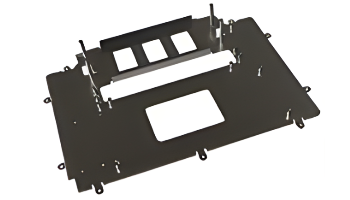

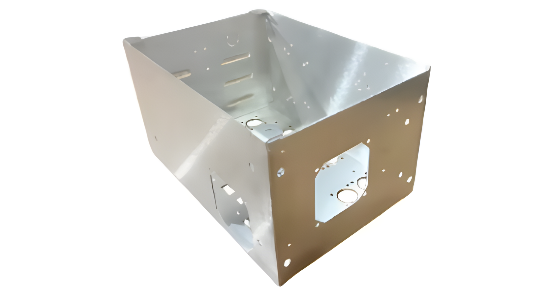

| Sheet Metal Product | Brackets / Enclosures / Sheet metal parts / Frames/ Decorative screen / Stamping parts / Panels / Covers |

| Enclosures | Sheet metal offers a cost-effective way to fabricate product device panels, boxes and cases for a variety of applications. We build enclosures of all styles, including rackmounts, “U” and “L” shapes, as well as consoles and consolets. |

| Chassis | The chassis we fabricate are typically used to house electromechanical controls, from small handheld devices to large industrial testing equipment. All chassis are built to critical dimensions to ensure hole pattern alignment between different parts. |

| Brackets | Baijinxin builds custom brackets and miscellaneous sheet metal components, well-suited for either lightweight applications or when a high degree of corrosion-resistance is needed. All hardware and fasteners that are needed can be fully built in. |

| Sample Cost | Free of Sample Cost. Normally is USD 35~110 per Style Of Special Design We Need Sample Charge, Can Refund when You Have Official Bulk Order. |

| Delivery Time | 1-25 days after order with prepayment based on products structure and quantity |

Custom Process

1. Inquiry

2. Mold design

3. Mold making

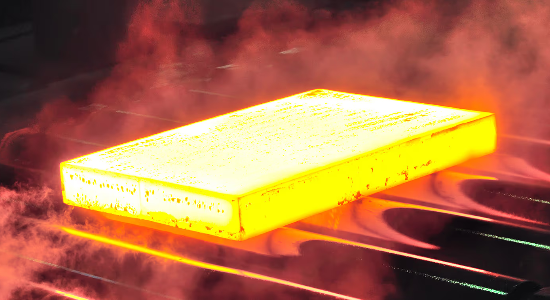

4. Stamping

5. Dimension inspection

6. Visual inspection

7. Package

8. Transportation

Material

Brass

Aluminum

Steel

Stainless steel

Processing capability

We are equipped with a wide range of advanced processing capabilities, allowing us to manufacture high-precision components using various metal forming techniques, such as progressive stamping, deep drawing, and blanking. Our state-of-the-art machinery, including CNC punching machines, hydraulic presses, and servo-driven systems, provides the versatility needed to process a diverse range of materials, including steel, aluminum, copper, and other alloys. This enables us to produce complex geometries and intricate designs with exceptional accuracy and tight tolerances.

We are committed to providing precise and high-quality stamped products by leveraging our extensive expertise in metal forming. Our flexible production processes ensure that we can create parts with complex designs and tight tolerances while maintaining cost-effectiveness and efficiency. The combination of cutting-edge machinery and skilled craftsmanship makes us a reliable partner for producing parts that demand the highest standards of precision.

Thanks to our diverse range of equipment and technologies, we can offer solutions for a wide variety of industries, including automotive, electronics, robotics, and more. Our ability to process multiple materials and produce detailed designs ensures that we can deliver custom parts that meet your exact requirements, no matter how challenging the project may be.

Additional processes

In addition to precision customized stamping, we offer a range of complementary processes to enhance the functionality and quality of stamped parts. These additional processes include:

Heat Treatment: For parts that need enhanced durability, strength, or hardness, heat treatment processes like annealing or tempering can be applied to the stamped metal.

Deburring and Finishing: To ensure smooth edges and surfaces, we provide deburring and finishing services, removing any sharp edges or imperfections from the stamped components.

These additional processes allow us to deliver fully customized, high-quality stamped products tailored to meet the exact needs of our customers across a variety of industries.