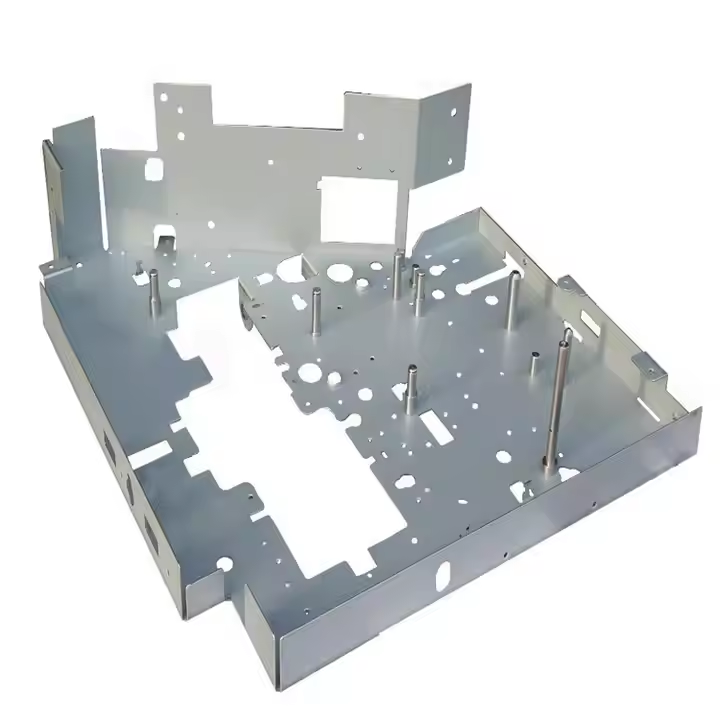

Product Description

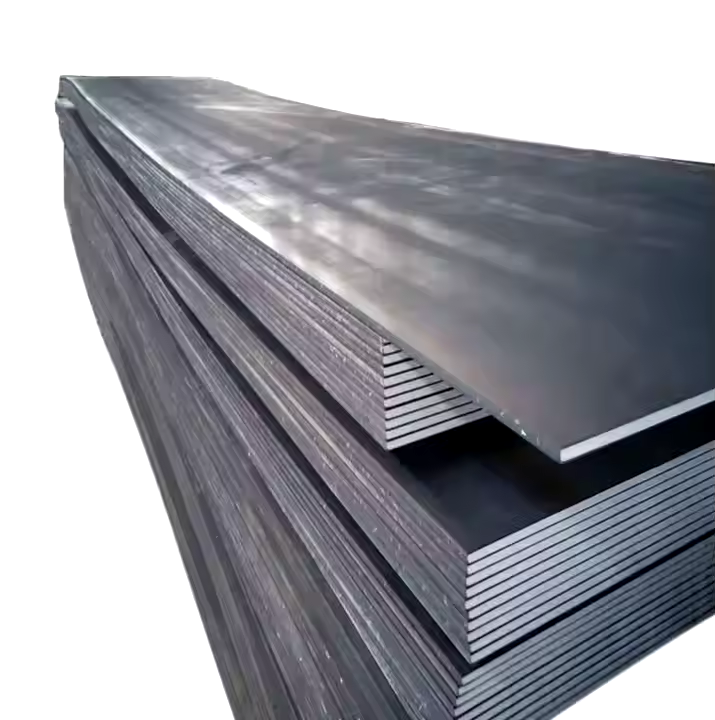

Our Custom Laser Cut/Sheet Metal service offers precision cutting for a wide range of applications, including architectural, industrial, and artistic projects. Utilizing advanced laser technology, we provide accurate, high-quality cuts on various metal materials, including stainless steel, aluminum, and copper. Whether you're looking for intricate designs, custom shapes, or functional parts, we ensure smooth finishes with tight tolerances. Our team works closely with you to deliver tailored solutions that meet your specific requirements. From prototypes to large production runs, we deliver fast, reliable, and cost-effective results for all your metal fabrication needs.

Product parameters

| List | Details |

|---|---|

| Brand Name | OEM Custom Laser Cut |

| Material | Steel, stainless steel, aluminum alloy, galvanized steel |

| Thickness | 0.5mm to 20mm |

| Process | laser cutting, punching ,bending and welding |

| Surface treatment | zinc plating, powder coating and anodized |

| Tolerance | +-0.5mm |

| package | cartons and pallets |

| Application | Electronic parts, machine parts, industry |

Custom Process

1. Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Material

Aluminum alloy

Metal Sheet

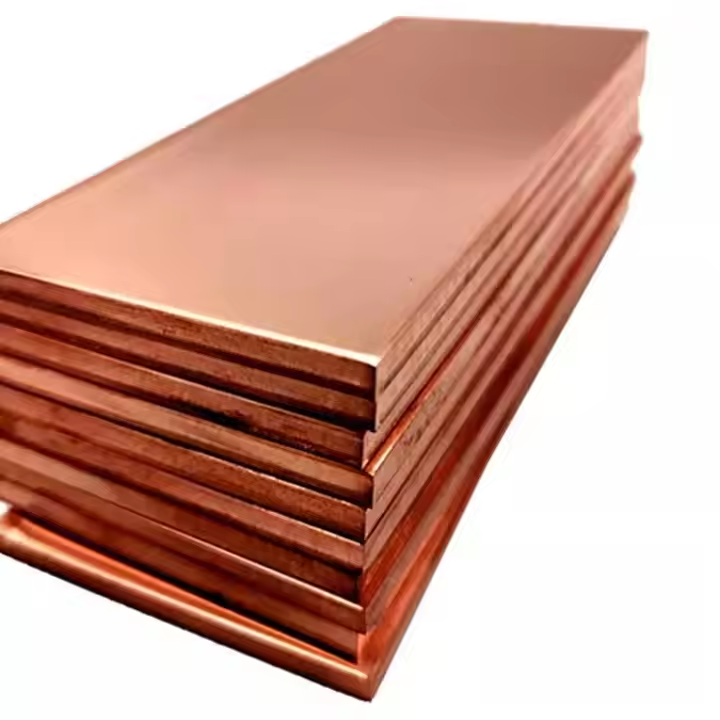

Copper Sheet

Brass Sheet

Quality Control

process for Custom Laser Cut/Sheet Metal ensures that every product meets the highest standards of precision and durability. We conduct thorough inspections at each stage of production, from initial design to final cut. All materials are tested for quality, and cuts are checked for accuracy, smoothness, and dimensional tolerance. Our team uses advanced measuring tools and visual inspections to identify any defects. Each product undergoes a final quality check to ensure it meets customer specifications. This rigorous QC process guarantees reliable, high-quality results for every order.

Processing capability

Our Custom Laser Cut/Sheet Metal processing capabilities are designed to meet a wide range of customer needs, delivering precision and versatility. We utilize state-of-the-art laser cutting technology to process various metals, including stainless steel, aluminum, mild steel, copper, and brass. With thickness capabilities ranging from thin sheet metals (as low as 0.2mm) to thicker plates (up to 25mm), we accommodate projects of all sizes and complexities.

Our laser cutters provide exceptional accuracy with tight tolerances, capable of intricate cuts, complex designs, and detailed patterns with minimal heat distortion. We also offer advanced nesting techniques to optimize material usage and reduce waste. In addition to cutting, we can handle processes such as engraving, etching, and scoring for custom applications.

Additional processes

For larger-scale projects, we support high-volume production runs without compromising on quality or speed. Our team is skilled in both small-scale prototypes and large-scale manufacturing, providing flexibility for a variety of industries, including automotive, aerospace, construction, and custom design. From concept to finished product, we ensure precision and consistency across all our laser-cut sheet metal components.