Product Description

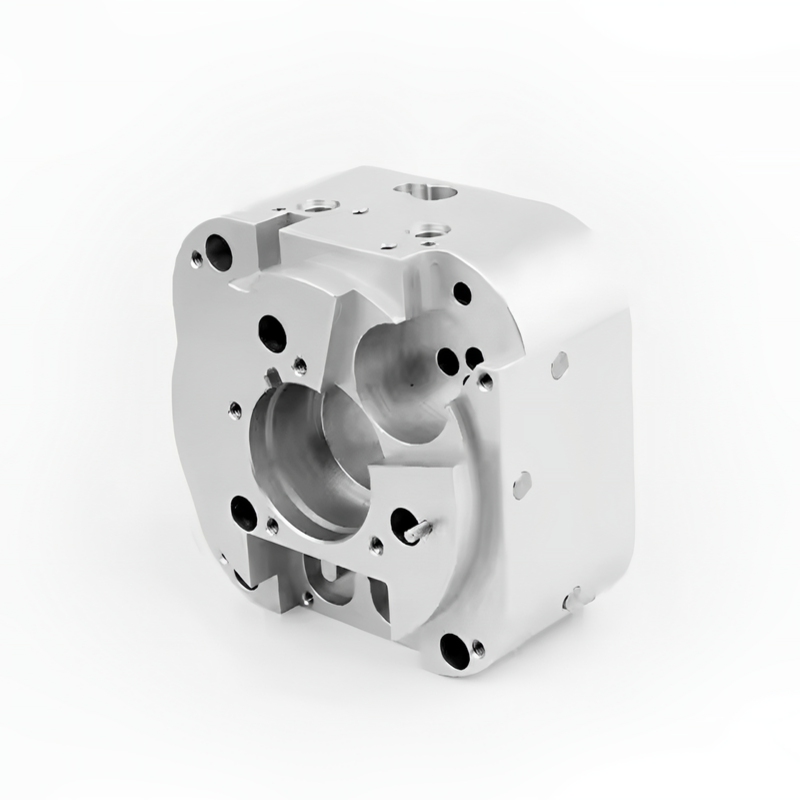

Experts in high-precision custom parts manufacturing, offering tailored solutions to meet specific requirements with exceptional accuracy, superior quality, and unmatched performance, ensuring reliability and excellence in every application

Product parameters

| Item Name | CNC machining service: Aluminum parts/steel parts/brass parts/plastic parts |

| CNC machining materials | Aluminum:5052/6061/6063/2017/7075/etc |

| Stainless Steel:303/304/316/412/etc | |

| Steel:Carbon steel/etc | |

| Brass:3602/2604/H59/H62/etc | |

| Plastic:Lucite/Nylon/Bakelite/etc | |

| Surface treatment | Anodizing and Polishing,Blacking/chrome plating/zinc plating/nickel plating,tinting,heat treatment |

| Product's Design and products Assembly | As per client's drawing or sample,beside we are also experienced in products assembly |

| MOQ | 1-5pc just for samples |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Robotic Equipment

Robot components such as gears and robot arms require precision to achieve high-precision movements and operations.

Electric Vehicles

The parts used in batteries and motors of electric vehicles require precision manufacturing for durability and efficient operation.

Industrial Machinery

Parts used in machinery, such as drive shafts and gear systems, that require high precision to keep the machinery running smoothly and efficiently.

Material

Aluminum Alloy

Stainless Steel

Copper

Quality Control

Quality control in high-precision custom manufacturing involves comprehensive and meticulous processes designed to ensure the highest level of accuracy and reliability. From the selection of premium materials to the use of advanced measurement technologies and rigorous inspections at every stage of production, we adhere to stringent international standards. Our commitment to precision and excellence guarantees that every component not only meets but exceeds exact specifications, providing superior performance and complete customer satisfaction

Processing capability

Processing capability in high-precision custom manufacturing encompasses a wide range of advanced techniques and technologies to handle complex designs and demanding requirements. With state-of-the-art machinery, including multi-axis CNC systems, and skilled technicians, we can achieve intricate geometries and tight tolerances across diverse materials. Our expertise extends to prototyping, small-batch production, and large-scale manufacturing, ensuring flexibility and consistency. Each step of the process is meticulously planned and executed to deliver exceptional quality and performance tailored to meet specific industry needs

Additional processes

Additional processes in high-precision custom manufacturing include advanced finishing techniques such as grinding, polishing, heat treating, and surface coating, all aimed at enhancing the functionality, durability, and aesthetics of the final product. These processes are carefully integrated into the production cycle to ensure superior performance and meet the specific requirements of each project. Whether it's improving wear resistance, achieving a smooth surface finish, or adding corrosion protection, our additional processes complement the core manufacturing steps, guaranteeing the highest level of quality and precision