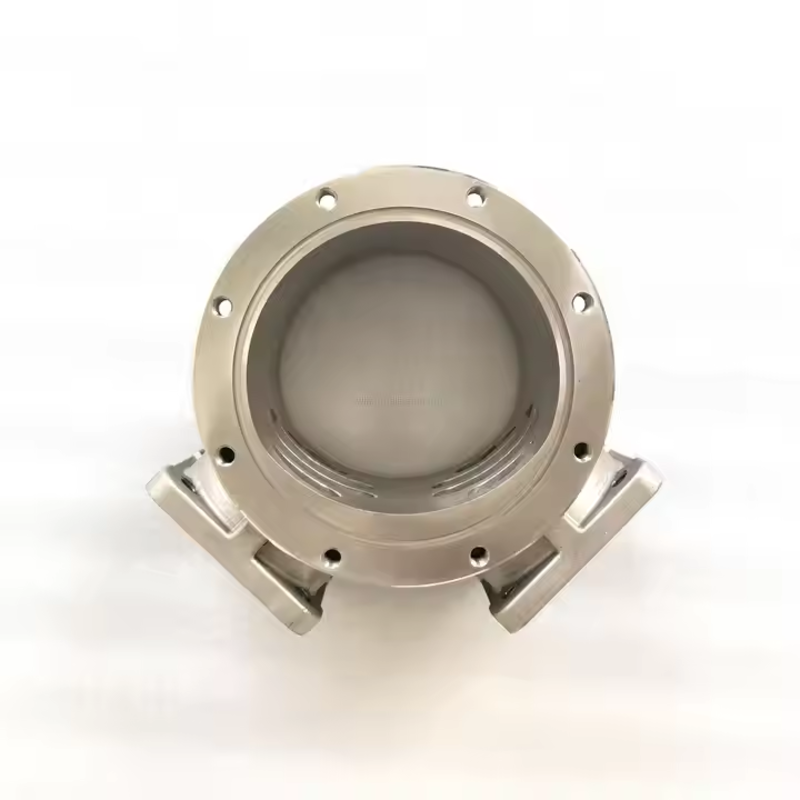

Product Description

Our metal spare brass processing services specialize in precision machining and fabrication of brass components for various industrial applications. Using advanced CNC lathes and milling machines, we deliver high-quality, custom brass parts with tight tolerances and superior surface finishes. We handle both small and large production runs, ensuring consistency and reliability in every piece. Whether for prototypes or mass production, our team ensures each part meets customer specifications and industry standards. Our brass processing capabilities include turning, milling, threading, and drilling. Trust us for durable, high-performance brass components tailored to your needs.

Product parameters

| List | Details |

|---|---|

| Product name | Professional Precision Cnc Machining Parts |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Precious Metals, stainless steel, Steel Alloys |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Material | Customers' Requirement |

| Equipment | 3/4/5 Axis CNC Machining Center |

| Color | Customers' Demands |

| Size | Customers' Demands |

| OEM/ODM | Provide OEM Service |

Custom Process

1. Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

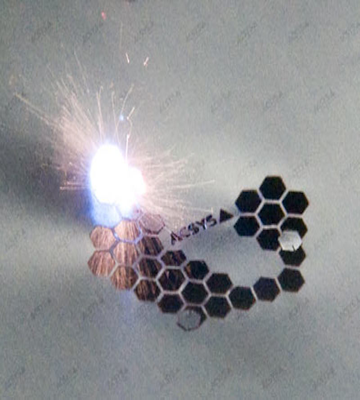

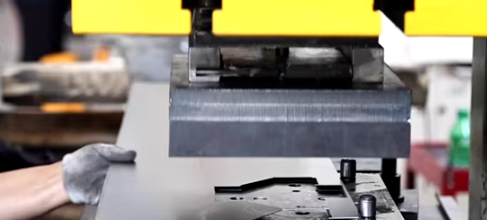

Process Type

Flame Laser Cutting

Melt Cutting

Remote Laser Cutting

Material

Carbon steel

Galvanized sheet

Aluminum alloy sheet

Stainless steel

Quality Control

QC process for metal spare brass processing ensures that every component meets the highest quality standards. Each part undergoes thorough dimensional inspection using precision measuring tools to verify tight tolerances and accuracy. We also check for surface finish quality, ensuring smooth, defect-free surfaces. In-process quality checks are performed to identify any potential issues early, preventing defects. Final inspections include functionality tests and conformance to customer specifications. Our rigorous QC procedures guarantee reliable, high-performance brass components for every order.

Processing capability

Our metal spare brass processing capabilities are designed to meet the needs of various industries, delivering high-precision, custom brass components. We utilize advanced CNC lathes and milling machines to perform turning, drilling, threading, and milling with exceptional accuracy. Our machines allow us to handle a wide range of brass alloys, ensuring the optimal material properties for each application. With capabilities for both small and large production runs, we can efficiently process parts of varying sizes and complexities.

Additional processes

Our team specializes in producing intricate designs with tight tolerances and high-quality surface finishes. We offer multi-axis CNC machining to create complex geometries, ensuring that all parts meet the exact specifications. Whether for prototypes or full-scale production, we ensure fast turnaround times and consistent quality. Additionally, we offer post-processing services such as deburring, polishing, and coating to enhance the final product's appearance and durability. From simple to highly detailed brass components, our processing capabilities are tailored to meet the diverse needs of our clients.