Product Description

A servo motor cylinder is a device that converts the rotating motion of a servo motor into a linear motion. It integrates the precise control performance of the servo motor and the function of the linear motion mechanism, and can realize the linear displacement control of high precision, high speed and high load capacity. It can achieve accurate linear displacement control, and the positioning accuracy can reach the micron or even nanometer level, which is very key in precision machining, semiconductor manufacturing and other fields.

Product parameters

| Model number | TYSC045 | |||||

| Motor mounting mode | direct-connected | reentrant | ||||

| Screw diameter (mm) | 12 | |||||

| Screw lead (mm) | 5 | |||||

| Effective travel (mm) | 0-300 | 0-300 | ||||

| Rated output (KN) | 0.4 | 3 | 0.4 | 0.3 | ||

| Reduction ratio | There is no | |||||

| Motor Power (W) | 0.1/0.2 | |||||

| Rated speed (mvs) | 200 | 250 | 200 | 250 | ||

| Internal anti-turning mechanism | Yes/no | |||||

| Limit switch | Yes/no | |||||

| Repeated positioning accuracy (mm) | ±0.02 | |||||

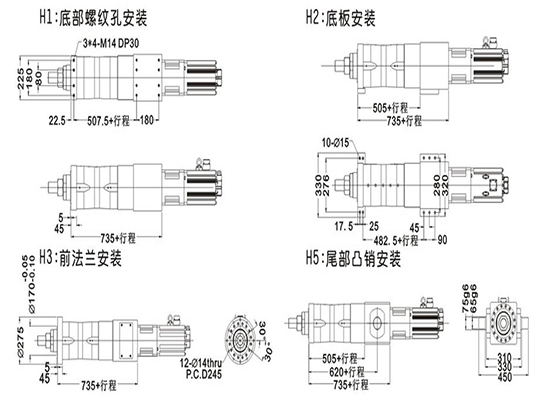

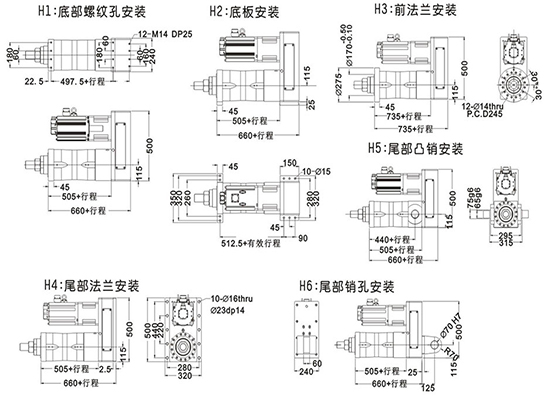

| Electric cylinder installation mode | Bottom thread hole | |||||

| Bottom plate | ||||||

| Front flange | ||||||

| Tail flange | ||||||

| Tail pin | ||||||

| Tail pin hole | ||||||

| custom | ||||||

| Load connection mode | Male thread | |||||

| Internal thread | ||||||

| Rod end joint bearing | ||||||

| Double bolt hole at rod end | ||||||

| custom | ||||||

| Class of protection | Ip65 | |||||

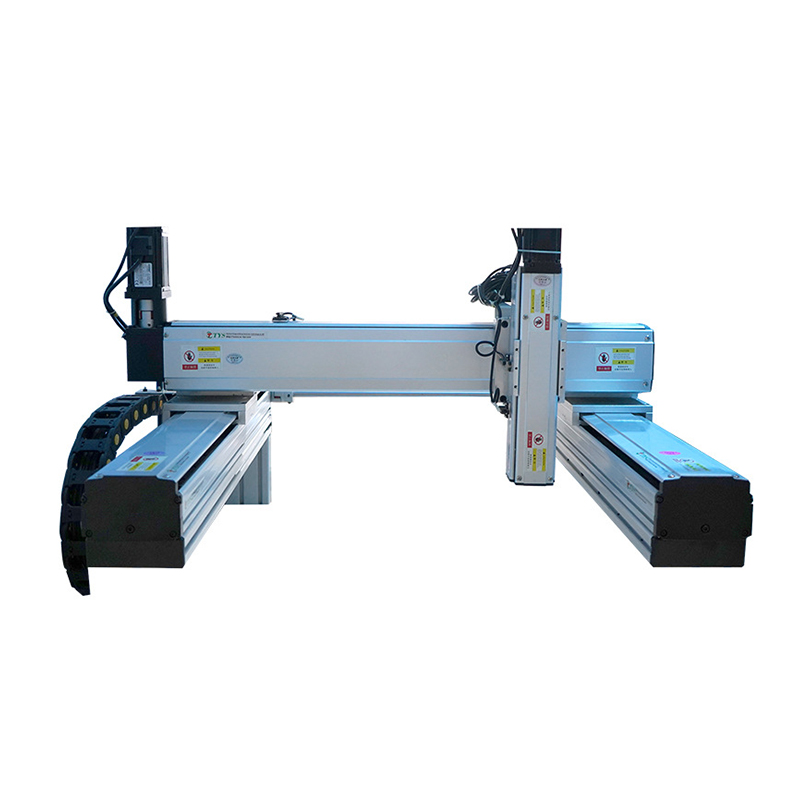

Product Display

- Energy saving and environmental protection, low noise, high speed, high precision, fast response, long life, can work in the harsh environment without trouble for a long time stable.

- Improve energy efficiency, increase heat loss, increase production speed, improve material utilization, extend uptime, and simplify maintenance processes.

- In terms of performance, the electric cylinder is more stable. It operates at an increased speed and power range, and can provide greater position accuracy.

Product independent design and development

With core engineering staff, independent design, research and development and production, it can meet customers' customized requirements for products, ensure the accuracy and strength of products, and have a wide range of products and thrust, which can reach 100 tons.

Quality control of the whole production process

Project follow-up responsibility to the engineer, production process in strict accordance with SIP/SOP implementation of production, subdivision management, process inspection, quality supervision and control of comprehensive production and manufacturing all completed in the factory, without outsourcing, quality is more guaranteed.

Size & Interface

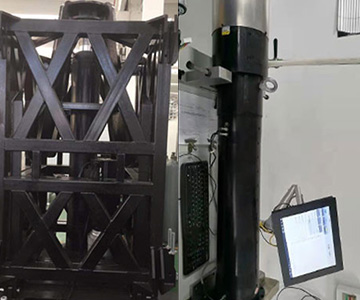

Application Cases

Suzhou Tongyousheng Electronic Technology Co., LTD., specializing in the production of servo electric cylinder, linear slide module, servo press, multi-dimensional free movement platform robot, robot series products. And provide Mitsubishi, Panasonic industrial control products, PLC, servo motor, inverter, touch screen, guide rail, screw, reducer series products.

Company Introduction

The company introduces foreign advanced technology, has specialized production equipment, advanced CNC processing equipment, high-precision test equipment, and has senior mechanical transmission designers, advanced design software, after years of struggle and struggle, Suzhou Tongyousheng Electronic Technology Co., Ltd. has established a leading advantage of "large scale, high output, stable quality" in the industry. Determined to strive for the development of Industry 4.0, we cooperate with a number of state-owned enterprises, top 500 units and universities. To provide customers with simple operation, excellent efficiency, stable performance, reasonable price of product equipment.

Cooperative partner

Service

- Pre-sales -- Help reasonable selection: project evaluation engineers docking, in-depth communication to understand the use of conditions, to confirm the appropriate selection and specifications, to give customers reasonable suggestions, effectively avoid problems in production

- Sales -- Ensure production delivery: dedicated engineers and business specialists docking, project managers to process control, active communication and interaction, timely detection of problems and timeliness communication, for the production delivery escort

- After-sales -- Timely response processing: after-sales engineering personnel docking, the same day response; And timely to the scene to confirm, discuss, solve and deal with problems, to meet customer production needs, to avoid downtime and production