Product Description

Our CNC 5-axis machining services provide high-precision and complex part manufacturing. Utilizing advanced 5-axis CNC machines, we can process intricate geometries and complex designs with tight tolerances. This technology allows for simultaneous movement along multiple axes, enabling the creation of parts with superior accuracy and finish. We work with a variety of materials including metals, plastics, and composites. Whether for prototypes or large-scale production, our 5-axis machining ensures optimal efficiency and high-quality results. Trust us for reliable, custom solutions tailored to your specific needs.

Product parameters

| List | Details |

|---|---|

| Brand Name | CNC 5Axis Machining |

| Material Capabilities | stainless steel, Aluminum |

| Type | Milling, Turning |

| Materials | Stainless steel |

| Surface finish | Anodize, Plating, Brushing, Polishing, Blackened, etc. |

| Inspection Equipment | CMM, Projection, Calipers, Micro caliper etc. |

| Drawing format | PDF, dwg, 2D, 3D etc. |

| Processing Type | 3/4/ 5 Axis CNC Machining |

Custom Process

1. Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

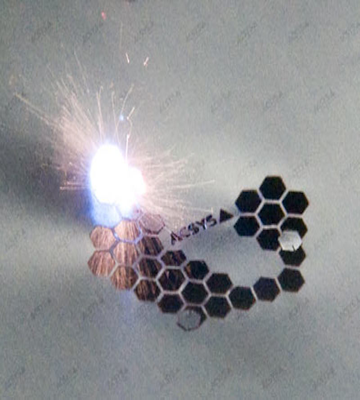

Flame Laser Cutting

Melt Cutting

Remote Laser Cutting

Material

Carbon steel

Galvanized sheet

Aluminum alloy sheet

Stainless steel

Quality Control

Our QC process for CNC 5-axis machining ensures the highest standards of precision and quality. Each part undergoes thorough dimensional inspection using advanced measurement tools to verify tight tolerances and accuracy. We inspect the surface finish to ensure smooth, defect-free surfaces that meet customer specifications. In-process quality checks are conducted to detect any potential issues early, preventing defects. Final inspections include functionality tests and verification against design requirements. Our stringent QC procedures guarantee reliable, high-performance parts with exceptional quality.

Processing capability

Our CNC 5-axis machining capabilities are designed to handle complex geometries and precision manufacturing with exceptional accuracy. With 5-axis machines, we can simultaneously move along multiple axes, allowing for intricate designs and precise detailing on all surfaces. This capability enables the production of parts with tight tolerances and superior surface finishes, making it ideal for industries such as aerospace, medical, automotive, and more.

Additional processes

We can process a wide range of materials, including metals, plastics, and composites, ensuring optimal material properties for each application. Our team is skilled in producing both prototypes and high-volume production runs. Additionally, we offer post-processing services like deburring, polishing, and coating to enhance product quality. With advanced technology and experienced technicians, we ensure efficient production and high-quality results for every project.