Product Description

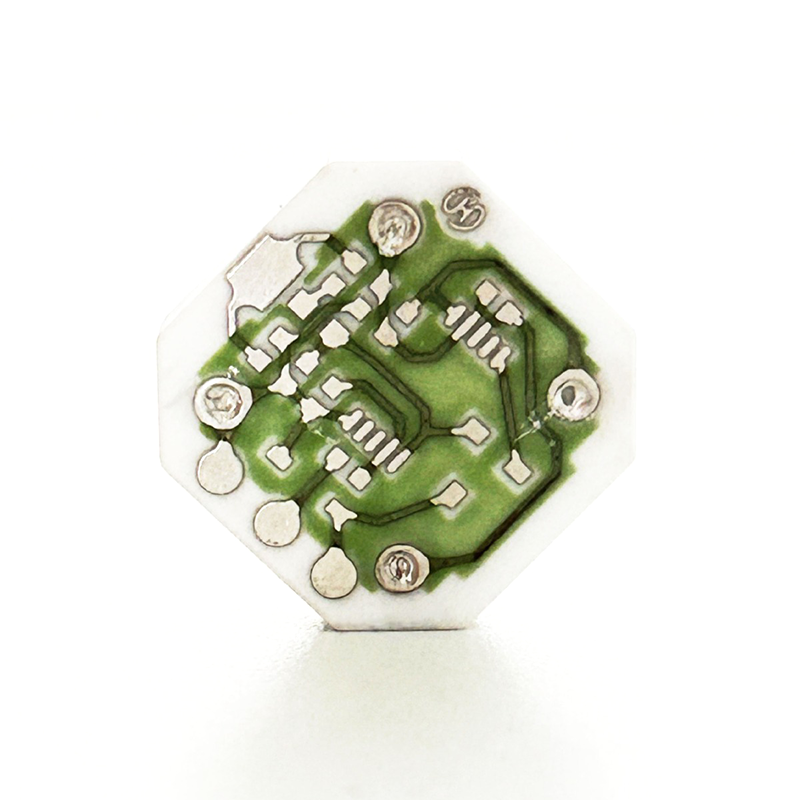

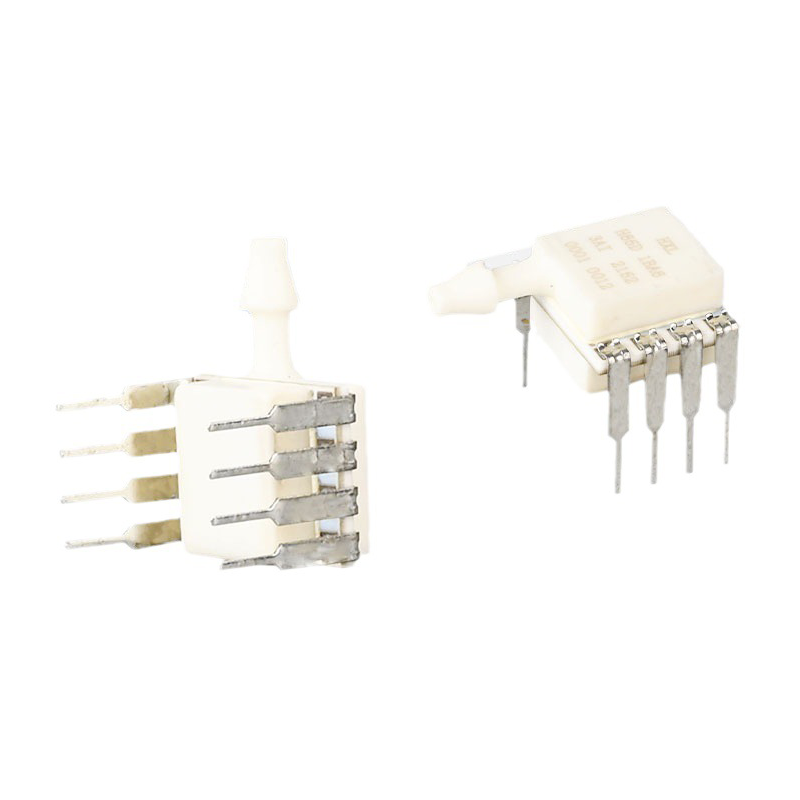

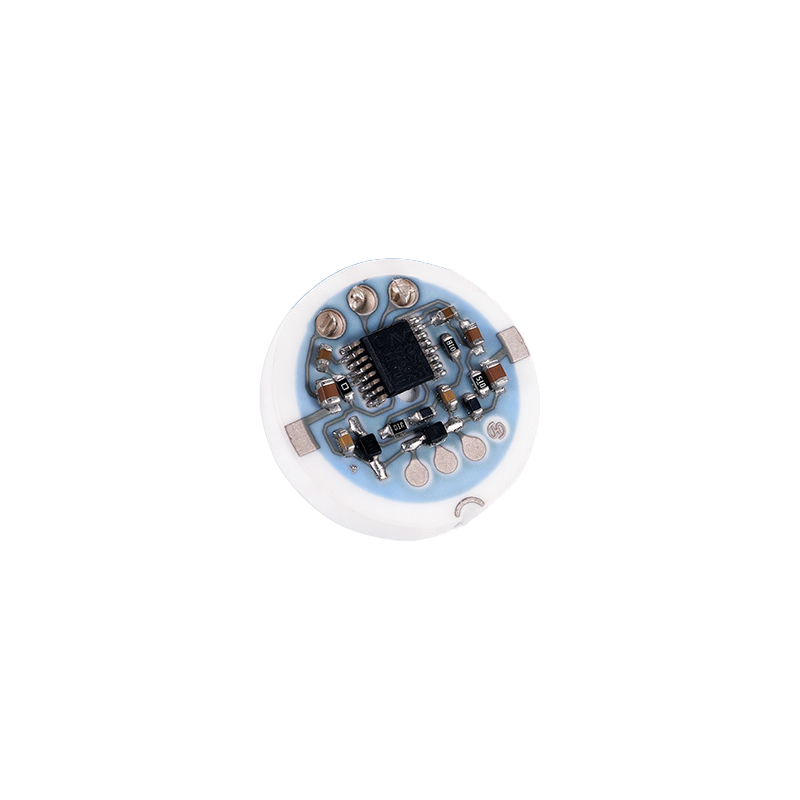

Concave film ceramic piezoresistive voltage output sensor module

The CPS18635MV1 and CPS18350MV1 series ceramic pressure sensors are made of refined alumina ceramic base, combined with highly stable sensitive materials, and are refined through processes such as silk screen printing, high-temperature sintering and laser resistance trimming.

The overall dimensions of CPS 18635MV1 are φ18*6.35mm, and the overall dimensions of CPS18350MV1 are φ18*3.50mm. Their unique circuit design significantly improves the reliability of the product. The temperature compensation circuit is integrated inside the sensitive element and has been laser-engraved, so that the internal bridge temperature drift signal is close to zero (≤0.02% FS/℃) within the normal use range (-20℃ to 85℃), which greatly reduces Temperature compensation calibration work required during the production of pressure sensors.

Ceramics have good thermal stability and creep resistance, operate in a temperature range of -40°C to 150°C, and exhibit excellent long-term stability.

The corrosion resistance of ceramics gives it significant advantages in the fields of refrigeration, chemical industry, medicine and environmental protection, and gradually replaces common diffused silicon pressure sensors.

Temperature-compensated ceramic piezoresistive sensor cores have become the first choice for pressure sensing elements in IoT applications due to their extremely high cost-effectiveness, and are widely used in pressure measurement of air, water, oil and other media. They are widely used in automobiles, air compressors, fire hoses, industry and home appliances, etc. Our company can customize pressure sensitive cores of various shapes and sizes according to customer needs.

Product parameters

| Parameter name | Parameter value |

|---|---|

| Series name | CPS18635MV1, CPS18350MV1 |

| Type | Concave film ceramic piezoresistive voltage output sensor module |

| Test pressure type | Gauge pressure |

| Dimensions (diameter x height) | φ18x6.35mm、φ18x3.50mm |

| Supply voltage | 5.0V ±10% DC (optional 8-32V DC ) |

| Operating current | <10 mA |

| Output voltage | ※ 0.5-4.5V DC |

| Overvoltage | < 12V DC |

| Operating temperature | -40 ℃~125℃ |

| Storage temperature | -40 ℃~125℃ |

| Nonlinearity | 0.25% FS Max |

| Hysteresis & repeatability | 0.25% FS Max |

| Output accuracy | ※ 0.5-4.5V DC |

| Response time | < 2mS |

| Insulation resistance | > 2KV |

| Long-term stability | Zero point @ 25℃: < 0.25% FS0 (no time accumulation) |

| Working life | More than 5 million pressure cycles @ 2-5Hz, 0~ full scale pressure ~ 0, 15~35℃ |

| Working medium | Oil, water, gas, refrigerant, coolant, chemical solvent, detergent, etc. |

Product Display

- Integrated integration, high product stability

- Supports customization of multiple output signals such as current, voltage, IIC, etc.

- Easy and convenient to use

- With excellent EMC protection and reverse polarity protection

- Excellent corrosion and wear resistance

- Various styles support customization

- High sensitivity

- High precision

- High stability

- Small size, easy to package

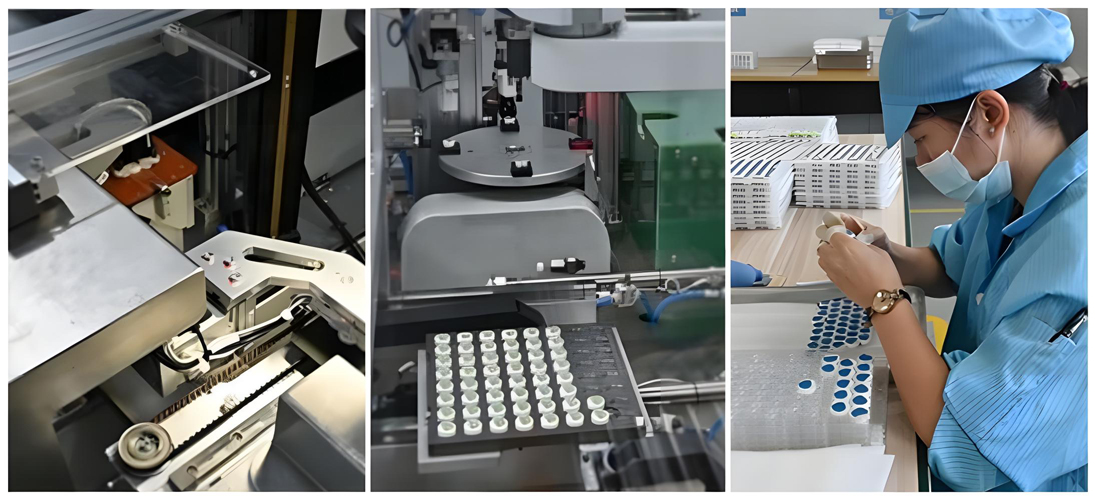

Quality Control

The company has a dust-free workshop of more than 4,000 square meters, equipped with a fully automated production line, which can produce more than 20,000 ceramic cores per day and more than 7 million per year. With strong R&D capabilities and rigorous production processes, the high quality and reliability of the products are ensured. So far, the company has obtained more than 50 patents and successfully passed ISO9001 and IATF16949 certifications. Huaxinlian Technology is committed to innovation, providing global customers with excellent innovative products and high-quality technical services, and jointly promoting the rapid development of the sensor industry.

Application Cases

In deep-sea submersibles, the concave film ceramic piezoresistive voltage output sensor module monitors the external water pressure changes in real time, providing accurate basis for the safe diving depth of the submersible and ensuring the smooth progress of deep-sea exploration missions.

On industrial automation production lines, the sensor module closely monitors the pressure of the hydraulic system to ensure stable pressure during the operation of equipment such as robotic arms, effectively improving the accuracy and consistency of product production.

In the aviation engine testing process, the concave diaphragm ceramic piezoresistive voltage output sensor module accurately measures the airflow pressure, providing key data support for engineers to analyze engine performance and optimize design, and promoting the continuous development of aerospace technology.

Service

- Support customized business, tailor-made on-board MEMS pressure sensors according to customer's special needs.

- Professional engineering team, with professional knowledge and experience, provides full-process technical support for products.

- Two-year warranty service, free repair or replacement for non-human quality problems during the period, to ensure peace of mind.