Product Description

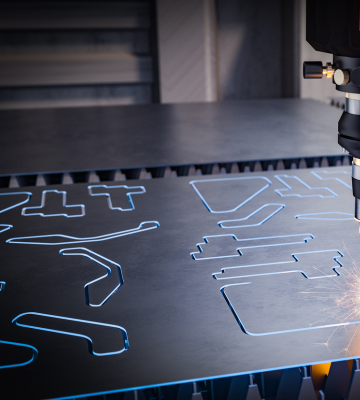

Versatile sheet metal fabrication machine for cutting, bending, punching, and forming with high precision. It optimizes production efficiency, ensures consistent quality, and supports diverse industrial needs.

Product parameters

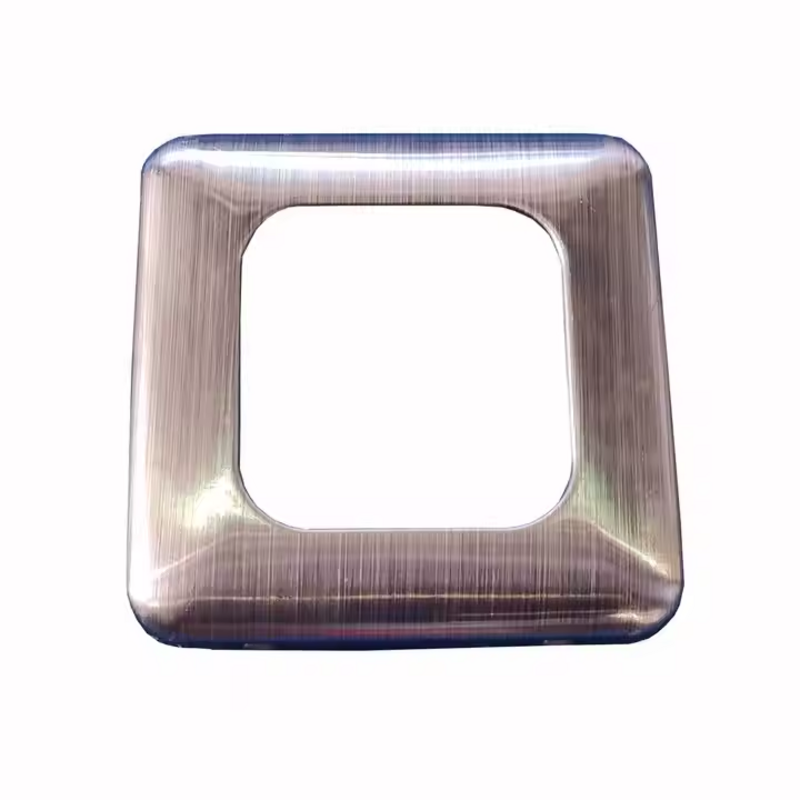

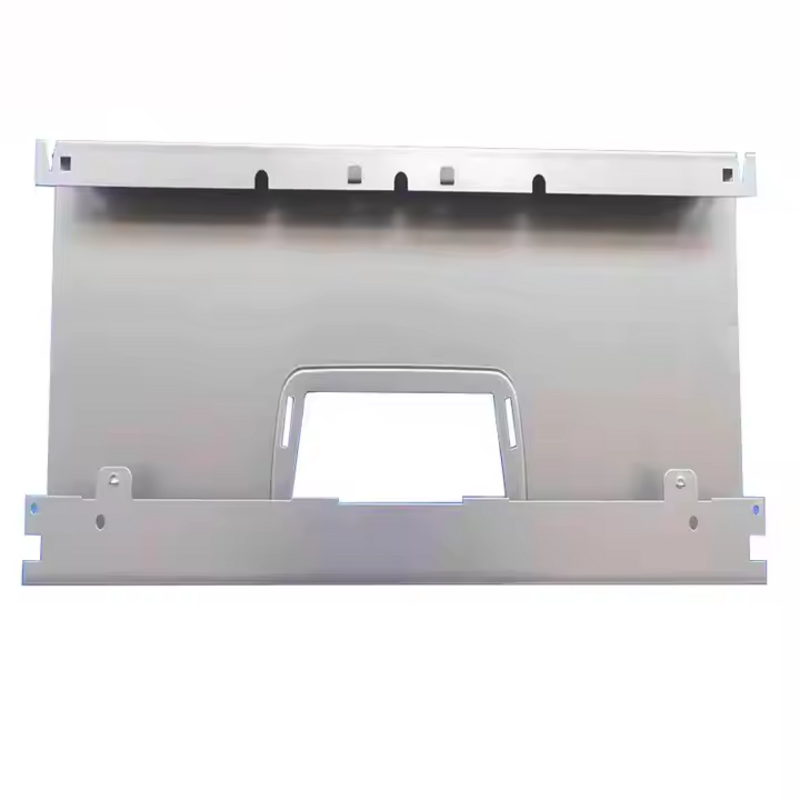

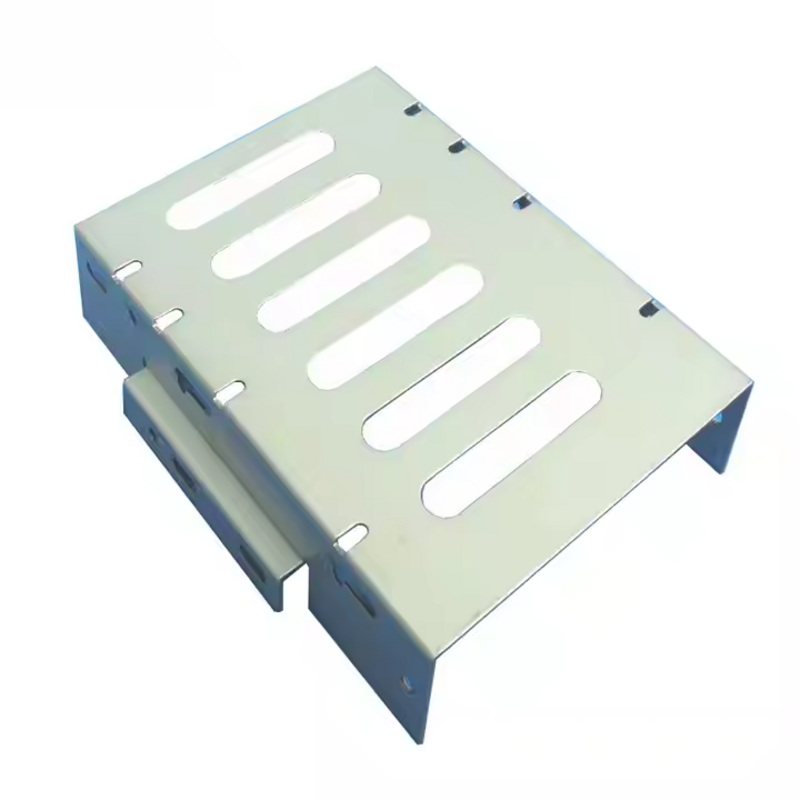

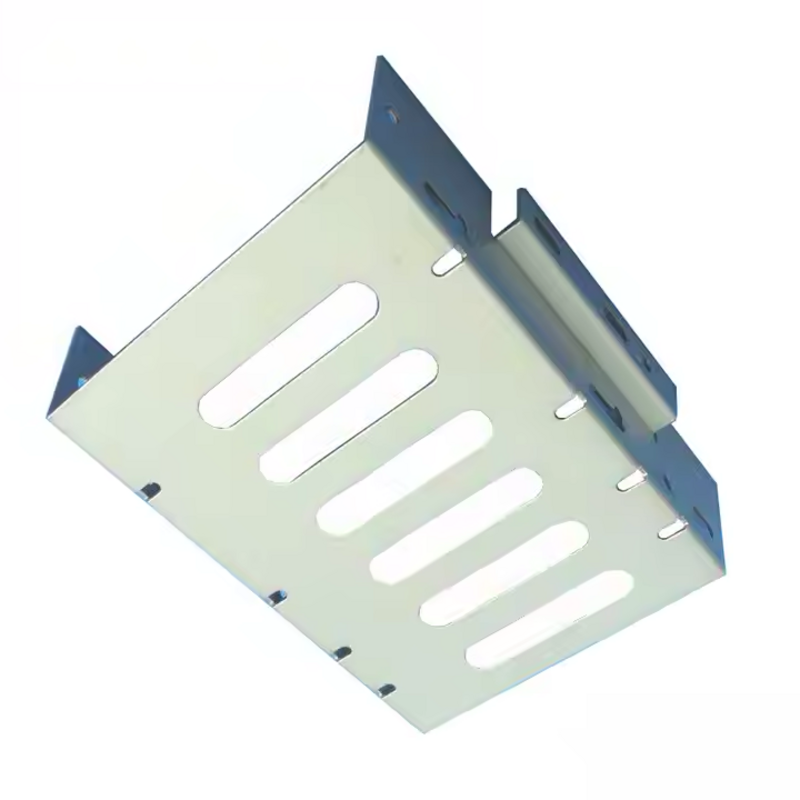

| Material | Cold steel, hot steel, zinc-plate sheet, SS, aluminum, copper, etc |

| Size | Custom as per the drawing or sample |

| Thickness of material | 0.2-20mm |

| Process | Laser cutting, stamping, bending, deep drawing, welding, etc |

| Tolerance | Generally +/-0.1mm |

| Surface finish | Painting,powder coating, galvanization,anodizing,etc. |

| Packing way | To be packed in carton box, carboard case,pallet or plywood case |

| Samples service | Available before bulk order |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Industrial Machinery

Metal fabrication parts are essential components in industrial machines, such as frames, covers, or load-bearing parts. Their durability and precision enable machines to operate continuously and safely

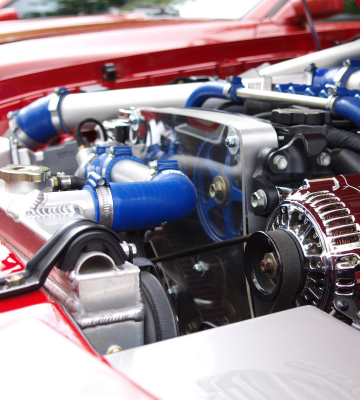

Automobiles and Vehicles

Fabricated metal parts are used in car bodies, load-supporting structures, and smaller components like brackets and joints. Their strength and flexibility in shaping enhance the safety and performance of vehicles.

Home Appliances

Metal fabrication parts are found in refrigerators, washing machines, and microwaves, serving as exterior panels, internal trays, or mechanical components. These parts ensure smooth surfaces, durability, and long-term functionality

Material

Copper

Aluminum Alloy

Stainless Steel

Quality Control

Quality control for a sheet metal fabrication machine ensures precision, consistency, and efficiency in cutting, bending, punching, and forming. Regular calibration and testing of components maintain accuracy within tight tolerances, while materials are inspected for durability. The control system and safety features are checked for reliability and operator protection. Trial runs verify machine performance with different materials and thicknesses, ensuring versatility. All tests are documented to maintain traceability and compliance with quality standards.

Processing capability

The processing capability of a sheet metal fabrication machine includes cutting, bending, punching, and forming with high precision. It handles various materials and thicknesses, ensuring tight tolerances and efficient production. Suitable for both small and large runs, the machine offers versatility and speed, while automation features improve accuracy and reduce waste.

Additional processes

Additional processes for a sheet metal fabrication machine include welding, assembly, and surface treatments such as coating, painting, or plating. These processes enhance the strength, durability, and appearance of the final product. The machine can also perform tasks like deburring and edge finishing to ensure smooth, clean surfaces. Some machines are equipped with automated systems for punching, marking, or engraving, providing added functionality for more complex designs. These additional processes help streamline production, reduce manual labor, and ensure high-quality results in various industrial applications.