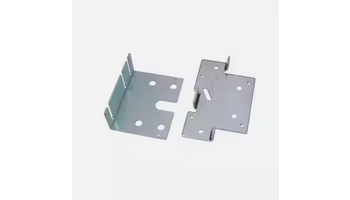

Product Description

Precision-crafted sheet metal parts offering durability and custom designs for various industries. Manufactured using advanced techniques like CNC machining and laser cutting, they meet tight tolerances and material requirements for high performance and reliability. Ideal for automotive, aerospace, electronics, and construction applications.

Product parameters

| Product Name | Sheet Metal Parts |

| Material | Mild Steel, Stainless Steel, Aluminium, Brass, Powder Coated, Copper |

| Process | CNC Laser Cutting, Turret Punching, CNC Bending, Sheet Metal Fabrication, Powder Coating |

| Application | Industry |

| Usage | Multiple Usages |

| Quality | ISO Standard Quality |

| Size | Customized(As per Drawings given by customer) |

| Custom Logo Possible? | Yes |

| Samples Available? | Yes |

| Service | Customized OEM |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Metal Furniture

Items such as tables, chairs, and shelving units rely on fabricated metal parts for strong frameworks, weight support, and aesthetic appeal due to their ability to be shaped and surface-coated

Medical Devices

Fabricated metal parts are crucial in medical equipment, including hospital beds, surgical instruments, and device frames. They require high precision and corrosion resistance to meet hygiene and safety standards

Electronics

Metal fabrication parts are used in computer casings, mobile phones, and communication devices, providing heat dissipation and structural protection for internal components. Their conductivity and impact resistance are key

Material

Copper

Aluminum Alloy

Stainless Steel

Quality Control

Quality control of sheet metal parts ensures precision, durability, and performance through material checks, dimensional measurements, and defect inspections. Strength, corrosion resistance, and surface finishes are tested to meet industry standards. Advanced tools like laser scanning and CMM verify complex geometries, and real-world testing ensures functionality. Documentation ensures traceability and compliance with specifications

Processing capability

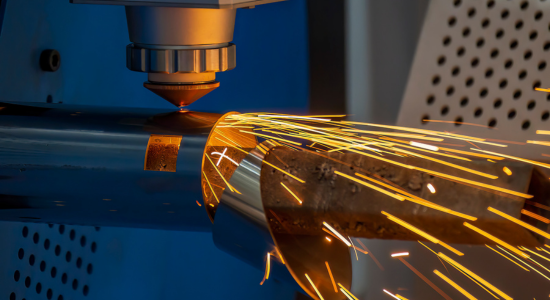

The processing capability of sheet metal parts includes cutting, bending, punching, stamping, and welding, using materials like steel, aluminum, and stainless steel. Advanced technologies like CNC machining and laser cutting ensure high precision, while additional processes like coating or finishing enhance durability and appearance

Additional processes

Additional processes for sheet metal parts include welding, assembly, surface treatments such as painting, coating, or plating, and processes like deburring and edge finishing. These steps improve the strength, appearance, and functionality of the parts, while ensuring smooth surfaces and corrosion resistance. Automated marking, engraving, and quality checks may also be applied to meet specific design and performance requirements