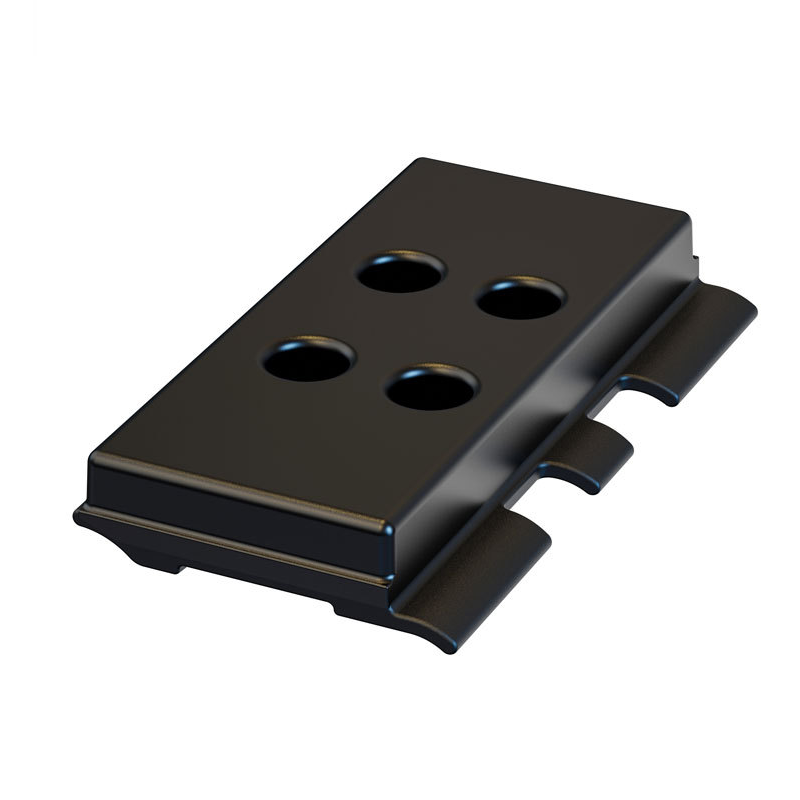

Product Description

Excavator rubber blocks are usually blocky, and their shape and size vary according to the specifications of excavator tracks and specific operational requirements. Generally speaking, one side of the rubber block will have a mounting structure connected with the track, such as a card slot or bolt hole, to facilitate firm installation on the track. On the other side is the working face in contact with the ground, which usually has a variety of patterns, such as block patterns, herringbone patterns, etc., which can enhance the grip of rubber blocks in different terrain.

Product parameters

| SIZE | L | W | H | Φ | Pitch |

|---|---|---|---|---|---|

| RP-CT300A | 300 | 95 | 56 | M12 | 90 |

| RP-CT400A | 400 | 125 | 60 | 12.5 | 135 |

| RP-CT400B | 400 | 125 | 60 | 12.5 | 135 |

| RP-CT400C | 400 | 125 | 60 | 13 | 135 |

| RP-CT400D | 400 | 125 | 60 | 12.5 | 135 |

| RP-CT400E | 400 | 125 | 60 | 13 | 135 |

| RP-CT400F | 400 | 125 | 60 | 12.5 | 135 |

| RP-CT400G | 400 | 125 | 60 | 12.5 | 135 |

| RP-CT400H | 400 | 125 | 60 | 12.5 | 135 |

| RP-CT450A | 450 | 145 | 72 | 15.5 | 154 |

| RP-CT450B | 450 | 145 | 72 | 13 | 154 |

| RP-CT450C | 450 | 145 | 72 | 14.5 | 154 |

| RP-CT450E | 450 | 130 | 72 | 14.5 | 140 |

| RP-CT450F | 450 | 130 | 72 | 12.5 | 140 |

| RP-CT450G | 450 | 130 | 72 | 12.5 | 140 |

| RP-CT500A | 500 | 165 | 82 | 16.5 | 171 |

| RP-CT500B | 500 | 165 | 82 | 17.5 | 175 |

| RP-CT600A | 600 | 180 | 102 | 21 | 190 |

| RP-CT600B | 600 | 180 | 102 | 18.5 | 190 |

| RP-CT600C | 600 | 180 | 102 | 21 | 190 |

| RP-CT600-154A | 600 | 145 | 82 | 15.3 | 154 |

| RP-CT600-171A | 600 | 165 | 89 | 16.2 | 171 |

| RP-ST600A | 600 | 219 | 75 | 18.5/20.5 | 190 |

Product Display

Increased friction: The excavator rubber block is installed at the bottom of the track, and one of its main functions is to increase the friction between the track and the ground. During the excavation operation, sufficient friction ensures that the excavator remains stable under various terrain conditions. For example, when excavators work on slippery muddy land or slopes with a certain slope, the pattern design of rubber blocks can be embedded in the ground to prevent the machine from sliding and ensure operation safety.

Protect tracks and ground: Rubber blocks can protect tracks. When the excavator is working, the track constantly fricts with the ground, and the rubber block can be used as a buffer layer to reduce the wear of the track. At the same time, for some more sensitive ground, such as urban roads, indoor ground or land that has been completed with greening, rubber blocks can reduce the damage of the track on the ground and avoid leaving deep track marks.

Shock absorption and noise reduction: the rubber itself is elastic, and the rubber block can absorb part of the vibration generated by the machine during the walking and operation of the excavator. This not only reduces the risk of damage to the internal parts of the machine due to vibration, but also provides a relatively comfortable operating environment for the operator. Moreover, the rubber block can reduce the noise generated during the operation of the excavator, especially in residential areas or construction areas with strict restrictions on noise, this function is particularly important.

Application Cases

It is widely used in crawler excavator, bulldozer, loader and other equipment. On construction sites, for example, the rubber shoe of an excavator can provide enough grip on soft ground to prevent the machine from sinking. At the same time, during the movement process, the rubber shoe can reduce the damage to the ground, which is particularly important for some construction scenarios that need to protect the ground (such as indoor demolition, landscape restoration, etc.).

Company Introduction

Tate Rubber is a professional manufacturer of rubber parts for the chassis of construction machinery and agricultural machinery. We are committed to providing our customers with professional technical services, quality products and timely and thoughtful service to help them achieve success in their respective fields.

For OEM customers, Tate's excellent technical team provides one-stop technical support. Customers can either use our existing specifications or customize according to their needs. During the design process, we fully communicate with the customer's technical team, design the structure of the track according to the customer's chassis frame and wheel train selection, and design the rubber formula according to the weight, speed and working conditions of the machine. This not only ensures a good match between the chassis and the track, but also ensures the stable and reliable performance and quality of the product.

Service

- Customized design: According to the needs of different customers, research and development and design of specific specifications and performance of rubber tracks. For example, in order to adapt to different types of construction machinery, agricultural machinery, etc., rubber tracks of different sizes, patterns and strengths are designed to meet the requirements of customers in various working conditions.

- Quality control: Establish a strict quality inspection system, from raw material procurement, production and processing to finished products, the whole process of quality control. For example, the hardness, tensile strength, wear resistance of rubber, as well as the strength and toughness of skeleton materials are tested to ensure that products meet relevant standards and customer quality expectations.