Product Description

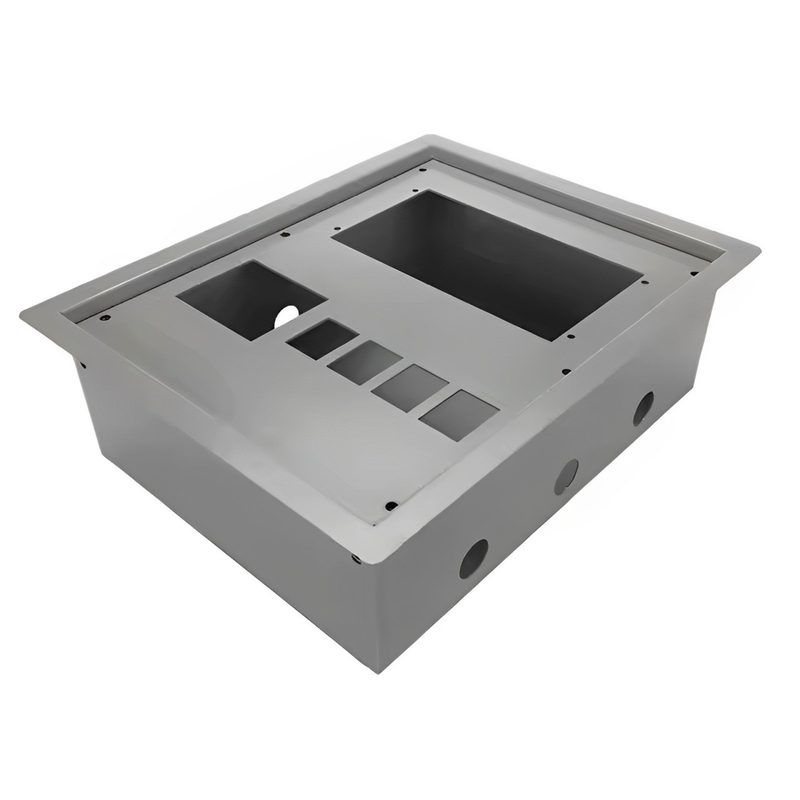

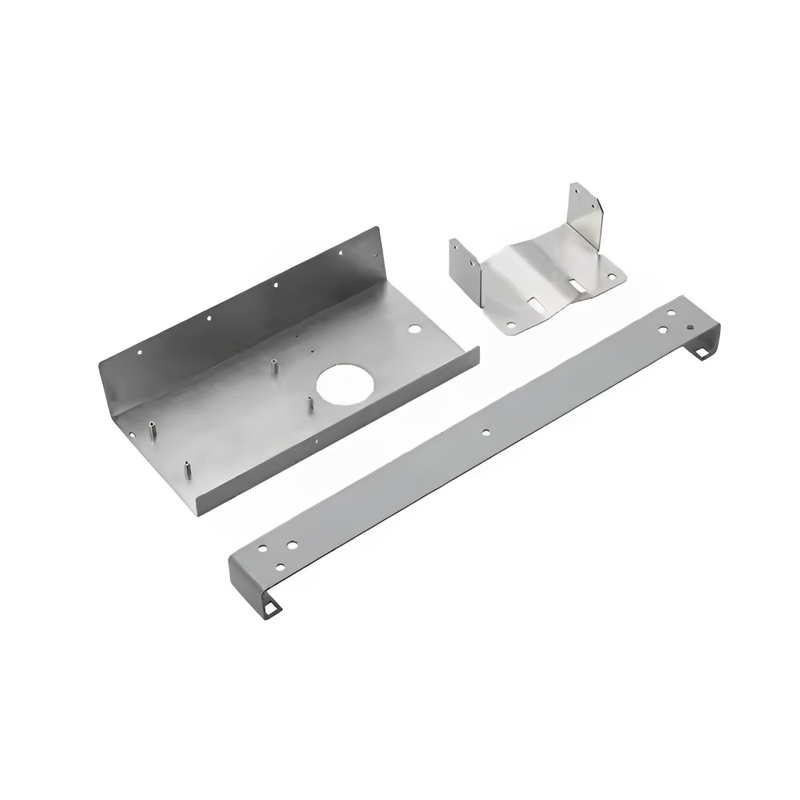

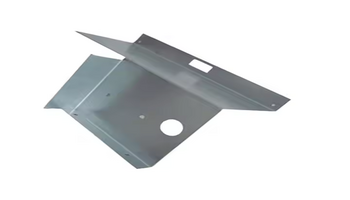

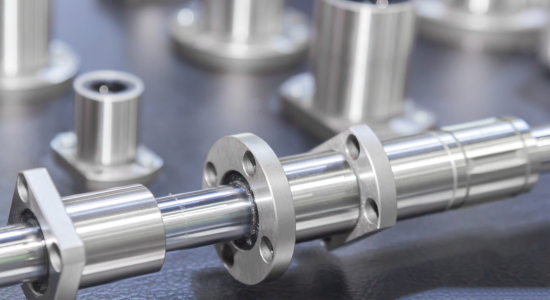

Precision stainless steel stamping parts, made with advanced technology for durability and accuracy, ideal for a wide range of industries. Engineered for reliability, performance, and custom applications, these parts meet high standards and demanding requirements.

Product parameters

| CNC Machining or Not | CNC Machining |

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Stainless steel, Steel Alloys |

| Micro Machining or Not | Micro Machining |

| Model Number | 1 |

| Brand Name | unofactory |

| Material | Steel |

| Product name | Metal Parts |

| Service | Customized OEM |

| Color | Customized Color |

| Quality Control | 100% Inspection |

| Our Service | One-step Service |

| QC Control | 100% QC Steps Inspection |

| OEM/ODM | Accecpted |

| Size | Customized Sizes Acceptable |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmatiol

Process Type

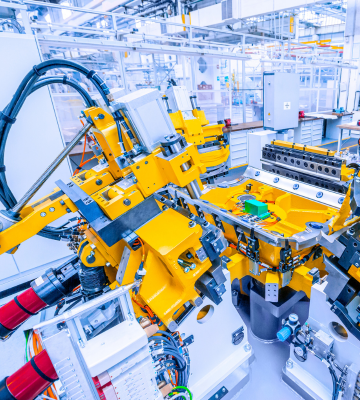

Industrial Machinery

Sheet metal is a critical material in the construction of industrial machinery, including components such as housings, panels, and structural supports. Its strength and ability to be precisely cut, bent, and welded allow manufacturers to produce robust machinery capable of handling heavy loads and extreme conditions

Solar Panels

Sheet metal is used for creating frames for solar panels due to its durability and ability to protect the solar panels from harsh weather conditions or corrosion from moisture. The sheet metal helps ensure that the panels are stable and extends their lifespan, making it suitable for outdoor use

Home Appliances

Sheet metal is used in the production of home appliances such as storage cabinets, shelves, and various household items because it offers durability and aesthetic appeal. It can withstand long-term use, is easy to clean, and is ideal for items that undergo frequent handling or movement in the home

Material

Copper

Aluminum Alloy

Stainless Steel

Quality Control

Quality control of stainless steel stamping parts ensures precision, durability, and performance through advanced inspection tools. We check dimensions, surface finish, and material integrity to meet customer specifications and industry standards, ensuring consistency and flawless functionality for various applications.

Processing capability

The processing capability of stainless steel stamping parts includes precision stamping, cutting, bending, and forming, using advanced machinery to ensure accuracy and high quality. We handle various material thicknesses and custom designs, delivering durable, reliable parts that meet strict tolerances and industry standards.

Additional processes

Additional processes for stainless steel stamping parts include surface treatments such as coating, plating, and polishing, as well as laser engraving and deburring. These processes enhance the durability, appearance, and functionality of the parts, ensuring they meet specific customer requirements and industry standards. Post-processing services also include assembly and prototyping, providing a complete solution that improves performance and efficiency across various applications.