Product Description

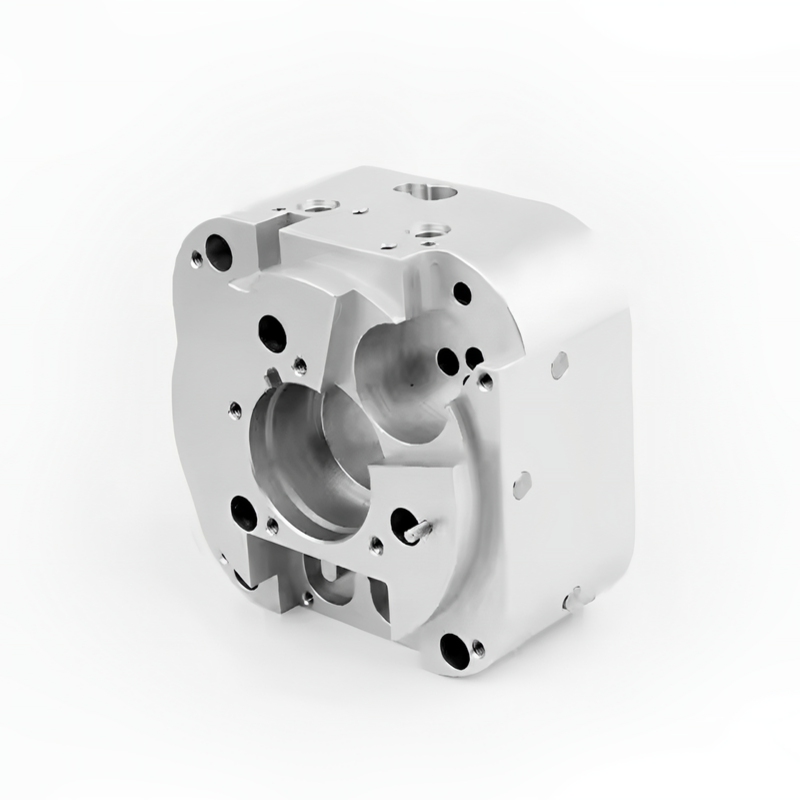

Custom CNC machining delivers precise, tailored manufacturing for complex parts, ensuring high accuracy, durability, and performance. Utilizing advanced technology, we meet the specific needs of various industries with tight tolerances and high-quality results.

Product parameters

| Product name | Custom CNC machining |

| keyword | Precision CNC milling processing |

| Material | Aluminum/brass/plastic/copper/titanium alloy/iron/stainless steel/steel alloy |

| Equipment | Three-axis, four-axis, five-axis machining center |

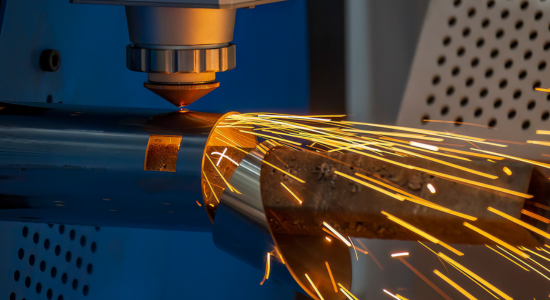

| Process | CNC milling;CNC turning |

| Application | Industrial equipment |

| Sheet format | 2D/(PDF/DWG)3D(IGES/STEP) |

| Surface treatment | Anodizing, electroplating |

| Serve | OEM customization |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Manufacturing Equipment

Parts used in manufacturing machinery, such as parts in automation systems and tools used in the production of other products that require precision in operation to increase productivity.

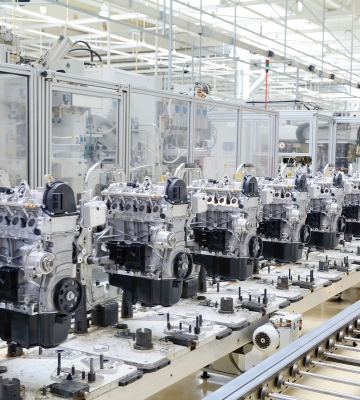

Automotive Manufacturing Machines

Used for producing complex parts like engine components or parts that require high precision in assembly. The Precision 5-Axis Impeller allows for multi-angle cutting, improving accuracy and reducing errors in the production of detailed parts.

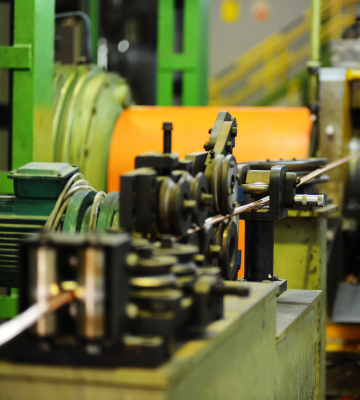

Industrial Machinery

Steel gear drives help machinery operate efficiently by supporting precise movements in the manufacturing process.

Material

Aluminum Alloy

Copper

Stainless Steel

Quality Control

Quality control in custom CNC machining is a rigorous process to ensure maximum precision and performance. Every step, from material selection to final production, is meticulously inspected using advanced measuring tools to guarantee accuracy and adherence to customer specifications. The process also includes durability testing and functionality checks to ensure that the final product is of the highest quality and ready for long-term use.

Processing capability

Custom CNC machining delivers precise, high-accuracy manufacturing for complex parts, working with various materials to meet specific design and performance needs. We ensure tight tolerances, excellent finishes, and reliable functionality for diverse industries.

Additional processes

Additional processes in custom CNC machining include surface treatments such as coating, plating, and polishing to enhance durability and appearance. We also offer engraving, deburring, and assembly services, ensuring the final product meets precise specifications and performs optimally for various applications. These additional steps ensure that parts are finished to the highest standards, providing functionality, aesthetics, and long-term reliability.