Product Description

Rubber shoes are usually installed on the tracks of tracked vehicles or equipment to increase the friction between the track and the ground, to disperse pressure and to protect the track. It is generally blocky structure, and the shape and size vary according to different application scenarios and equipment requirements. Some rubber shoes have patterns designed to enhance their grip on a variety of difficult terrain (such as mud, sand, snow, etc.).

Product parameters

| Specifications of Split-type | |||||||

|---|---|---|---|---|---|---|---|

| SIZE | L | W | A | B | C | D1 | D2 |

| PVS-300 | 300 | 300 | 89 | 57 | 220 | 13.5 | 16 |

| PBR-320 | 320 | 320 | 89 | 57 | 220 | 13.5 | 16 |

| PBR-400 | 400 | 400 | 89 | 57 | 320 | 13.5 | 16 |

| PVS-300-4M | 300 | 300 | 89 | 57 | 220 | 13.5 | 14 |

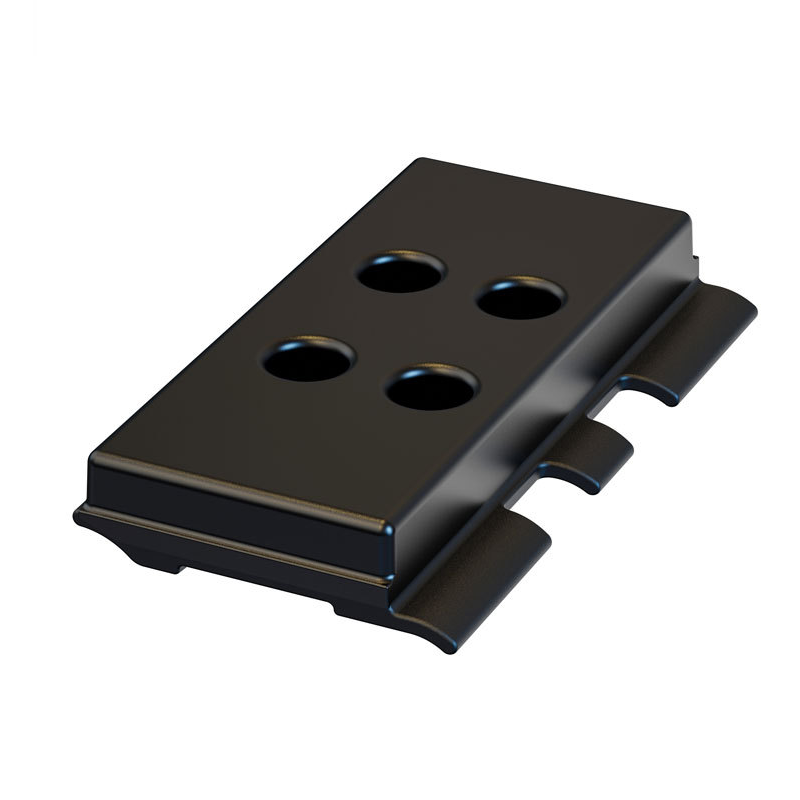

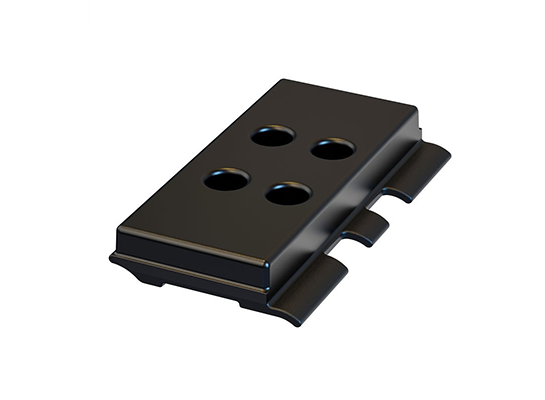

Product Display

Elasticity and flexibility: The rubber material itself has good elasticity, which makes the rubber shoe can effectively cushion the impact from the ground during the equipment driving. For example, when a crawler excavator is working on rough ground, the rubber shoe can absorb the vibration of the machine itself, reduce damage to the internal parts of the equipment, and provide a more comfortable operating environment for the operator.

Wear resistance: In order to cope with long-term friction and wear, rubber shoes are usually made of rubber formulations with better wear resistance. High-quality rubber shoes can travel long distances on various rough surfaces without wearing out too quickly.

Corrosion resistance: Rubber shoes also need to have a certain amount of corrosion resistance, because in some working environments (such as the factory floor containing chemical substances, seaside salt spray environment, etc.), you may be exposed to corrosive substances. Specially formulated rubber can resist the erosion of these chemicals and extend the service life of the shoe.

Application Cases

It is widely used in crawler excavator, bulldozer, loader and other equipment. On construction sites, for example, the rubber shoe of an excavator can provide enough grip on soft ground to prevent the machine from sinking. At the same time, during the movement process, the rubber shoe can reduce the damage to the ground, which is particularly important for some construction scenarios that need to protect the ground (such as indoor demolition, landscape restoration, etc.).

Company Introduction

Tate Rubber is a professional manufacturer of rubber parts for the chassis of construction machinery and agricultural machinery. We are committed to providing our customers with professional technical services, quality products and timely and thoughtful service to help them achieve success in their respective fields.

For OEM customers, Tate's excellent technical team provides one-stop technical support. Customers can either use our existing specifications or customize according to their needs. During the design process, we fully communicate with the customer's technical team, design the structure of the track according to the customer's chassis frame and wheel train selection, and design the rubber formula according to the weight, speed and working conditions of the machine. This not only ensures a good match between the chassis and the track, but also ensures the stable and reliable performance and quality of the product.

Service

- Customized design: According to the needs of different customers, research and development and design of specific specifications and performance of rubber tracks. For example, in order to adapt to different types of construction machinery, agricultural machinery, etc., rubber tracks of different sizes, patterns and strengths are designed to meet the requirements of customers in various working conditions.

- Quality control: Establish a strict quality inspection system, from raw material procurement, production and processing to finished products, the whole process of quality control. For example, the hardness, tensile strength, wear resistance of rubber, as well as the strength and toughness of skeleton materials are tested to ensure that products meet relevant standards and customer quality expectations.