Product Description

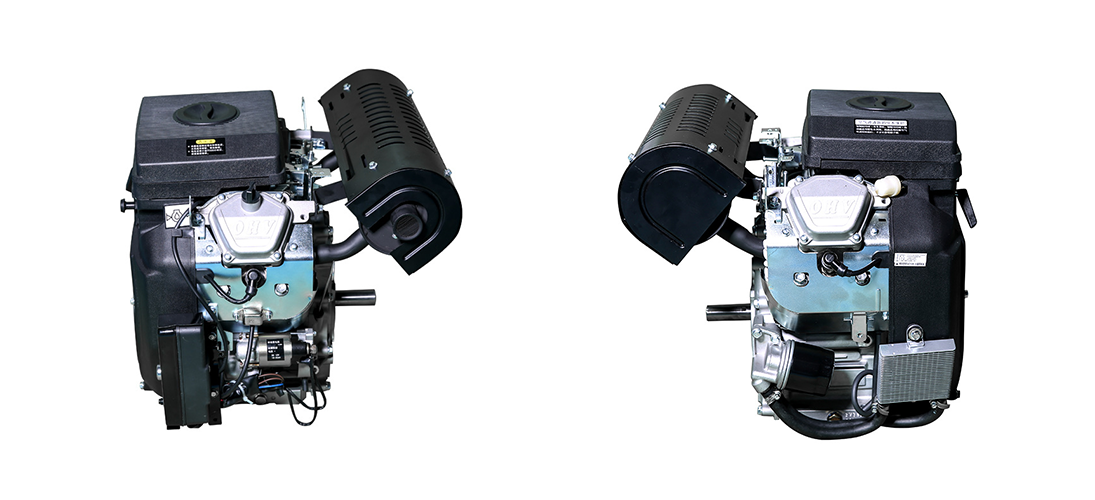

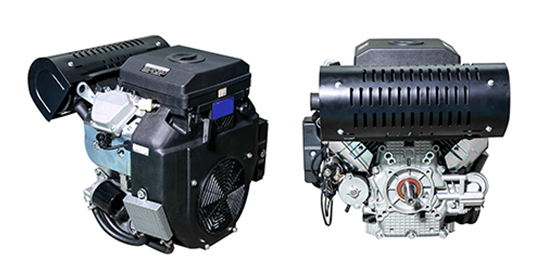

A two-cylinder power gasoline engine is an internal combustion engine that uses gasoline as fuel and has two cylinders. It uses the energy generated by burning gasoline to push the piston movement, and then converts the reciprocating motion of the piston into the rotating motion of the crankshaft, thus output power. Like a normal gasoline engine, it includes four strokes of intake, compression, work and exhaust. In the intake stroke, the piston moves down, the intake valve opens, and the combustible mixture of gasoline and air is drawn into the cylinder; During the compression stroke, the intake valve and exhaust valve are closed, the piston moves upward, and the mixture is compressed; When the power stroke is done, the spark plug ignites the mixture, generates high temperature and high pressure gas to push the piston downward, and drives the crankshaft to rotate and output power through the connecting rod; Exhaust stroke, the exhaust valve opens, the piston moves upward, and the burned exhaust gas is discharged from the cylinder.

Product Features

Power output: Compared with a single cylinder engine, a two-cylinder engine at the same displacement, the power output is more powerful and more stable. The two cylinders work alternately, and the power is closely connected, which reduces the fluctuation of the power output and provides more sufficient power when accelerating and climbing.

Fuel economy: The two-cylinder gasoline engine, through advanced technology, is able to provide enough power at low revs, while maintaining fuel economy at high revs, improving fuel efficiency and allowing the vehicle to run longer.

Working stability: Because the two cylinders work with each other, the vibration and noise of the two-cylinder engine during operation are greatly reduced compared with the single-cylinder engine, and the work is more stable.

Environmental performance: The two-cylinder gasoline engine uses low-emission technology to effectively reduce pollutant emissions and comply with increasingly stringent environmental regulations.

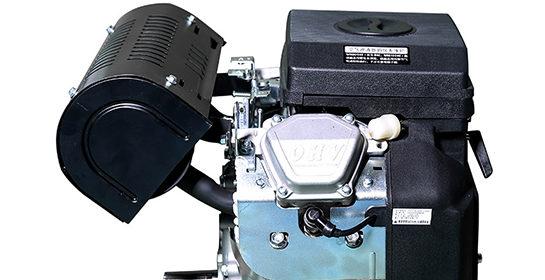

Increase the fuel tank to meet the long-term demand and continue to work for a long time

Improve work efficiency, the generator has manual and electric start to improve work efficiency

Quality assurance, strict selection of materials, quality assurance of low fuel consumption

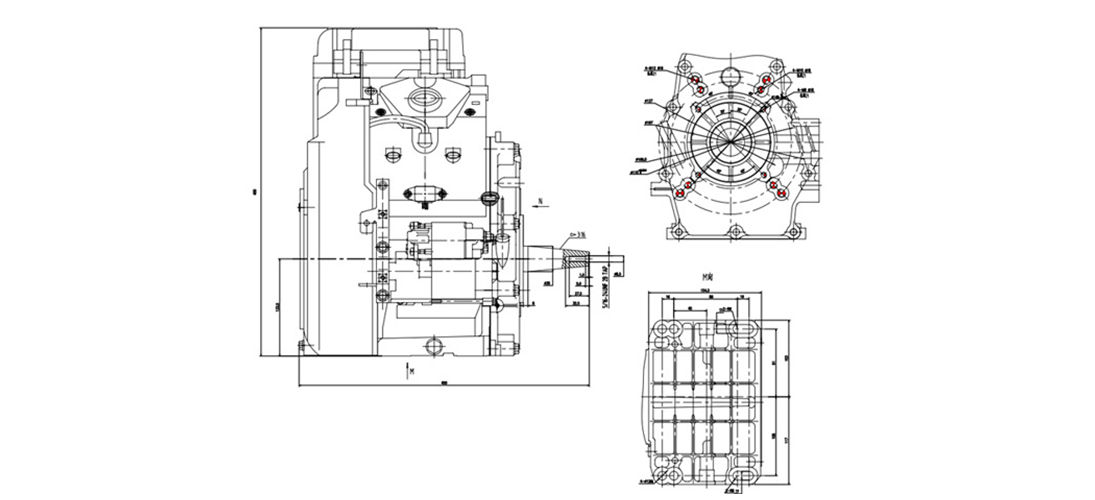

Structure Diagram

Product parameters

| 名称 | 参数 | 名称 | 参数 |

|---|---|---|---|

| Unit type | Gasoline two-cylinder power | Engine type | 2V78F-2 |

| Engine type | V Twin cylinder/four stroke/forced air cooling | ||

| Cylinder diameter x stroke | 78*72mm | displacement | 688ml |

| Ignition system | Compression combustion | Oil consumption | <370g/kw.h |

| Starting mode | Electric starting | Maximum torque | 43.5N.m/2500/rpm |

| Maximum power | 13.5/3600 kw/RPM | Compression ratio | 8.5:1 |

| Air filter | semi-dry | Oil volume | 1.4L |

| Net weight | 47KG | Overall size | 595*550*540mm |

| [Note] Manual measurement error, please refer to the actual. Due to different monitors, and shooting light and other irresistible factors, color difference can not be completely avoided. | |||

Customer Case

Our Factory

Product Certificate

Service

- Experienced in the industry:More than ten years of production experience, quality is more secure, and we are also a set of design, development, production, sales as one of the enterprises. The Group has a small general machinery and power engine factory in Chongqing, which is equipped with a number of automatic assembly lines, perfect quality system and testing facilities, and produces 300,000 general machinery and power engines every year.

- More advanced production equipment:It has more than 200 sets of equipment, including product testing, production line, machining, etc. In addition, there are a number of general machinery and power production lines. Has formed an annual output of 30W production capacity, the company attaches importance to science and technology and research and development, with soft, invention and 15 utility models, and in 2022 to obtain the national high-tech enterprise recognition; Products have CE, Euro 5 and other certifications.

- Strict quality control:From the raw materials, production, shipping and other links have strict inspection, the company has formulated the "integration of the world's advanced technology, to create stronger technology, to serve global users" strategic goals. Adhere to the "unity, struggle, truth-seeking, innovation" business philosophy, adhere to the "product oriented, with integrity to stabilize the market" business purposes. We always put product quality and customer interests first to provide customers with better products and services to achieve mutual benefit and win-win!

- Professional service team:We strive to serve customers, serve the community, and serve everyone is a foothold for our development. We not only provide good products, but also ensure considerate service, and we always strive to provide customers with as much added value as possible.

Pack

Microgenerator packaging is first and foremost designed to protect generators from physical damage, such as collisions, squashing and vibration, during transportation and storage. Because there are many precise parts inside the generator, such as rotors, stators, circuit boards, etc., these parts are easily damaged by external forces. Secondly, in order to prevent moisture and dust, to prevent external environmental factors from adversely affecting the performance of the generator. For example, a humid environment may cause the metal components inside the generator to rust, and dust may block heat dissipation channels or affect electrical insulation performance.

Carton: can easily print product information, identification and transportation precautions. The strength of the carton can be selected according to the weight and transportation requirements of the generator, and double-layer corrugated cartons are generally used to pack the micro generator. This kind of carton has good compression and puncture resistance, and can withstand a certain degree of pressure during stacking and handling.

Wooden box: For some micro-generators with longer distribution distances or higher protection requirements, wooden boxes will be used. The construction of wooden cases is stronger and can provide greater protection. Especially for export products or generators that need to be transported over long distances and in complex environments, wooden boxes can better withstand external pressure and collisions.

Transport

During the transportation process, to ensure the completeness of the transportation process and the safety of the equipment, do the following related work:

- Package inspection: Before shipping the generator, carefully check the package is in good condition. Make sure the inner packaging material (e.g., foam, bubble wrap) is tightly wrapped around the generator and is not loose or displaced. The outer packing (carton or wooden case) should be strong, tightly sealed, and the signs on the packaging (such as fragile sign, moisture proof sign, upward sign, etc.) should be clearly visible.

- Document preparation: Prepare relevant shipping documents, including product manuals, warranty cards, shipping lists, etc. If it is cross-border transportation, it is also necessary to prepare customs declaration documents, certificates of origin and other necessary documents.

- Fixed generator: If the generator is transported in a transport vehicle (such as a truck, a container), it needs to be fixed. Tools such as ropes and wooden wedges can be used to prevent the generator from being damaged by shaking and collision during transportation. For example, in the truck compartment, after the generator is placed in the right position, it is tied with the fixed point of the compartment with a rope to ensure that it does not shift during the vehicle.