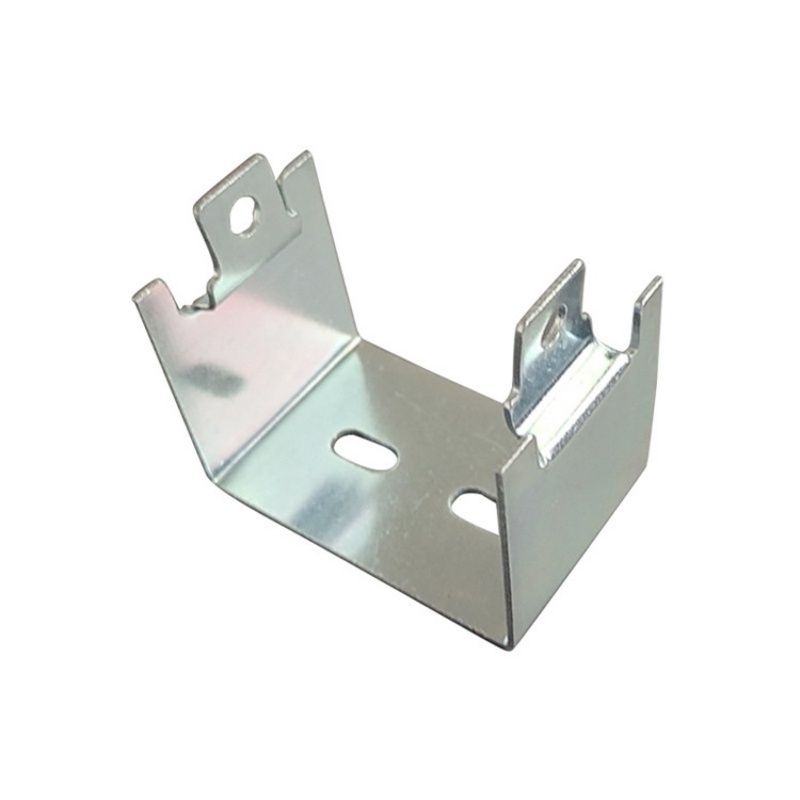

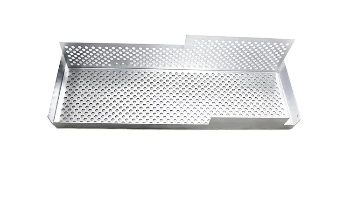

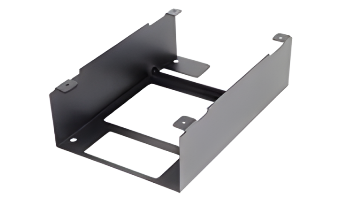

Product Description

Our R&D team works closely with clients to ensure that the products we provide are not only of the highest quality but also incorporate the latest technological advancements. From initial design to final production, we collaborate with you at every step to ensure the end product exceeds your expectations.

When you choose ERIK, you are not just selecting a supplier – you are gaining a reliable partner who will support your business growth and help you succeed. We pride ourselves on our customer-first approach, always ensuring that your needs are met with professionalism, expertise, and precision.

Product parameters

| Service Type: | OEM/ODM customized by customer provide "Drawing" or "Sample" or "Just an Idea" |

| Material: | Steel, Stainless Steel, Aluminum, Copper, SPCC, SGCC, SECC, SPTE etc |

| Surface Treatment: | Powder Coating, Color Anodizing, etc. Multiple choices see Surface Treatment display |

| MOQ: | 1 PCS |

| Lead Time: | *Sample: within 5 days. *Mass Production: within 10-20 days after receiving the deposit *Expedite Order: Service available |

| Package: | Support customization for customer's demand. Generally package material are Plastic bags/Interleave paper + Carton + Plywood Pallet/Crate |

| Trade Terms: | EXW, FOB, CIF, CFR etc |

| Payment Terms: | *New customer: T/T 30% deposit, 70% balance after shipping out *Old customer: 100% Net 30 days |

Custom Process

1. Inquiry

2. Mold design

3. Mold making

4. Stamping

5. Dimension inspection

6. Visual inspection

7. Package

8. Transportation

Process Type

Blanking

The process of cutting out a piece from a larger sheet of metal. The cut piece, called a "blank," is separated from the rest of the material. This is often the first step in the production of parts and is used to produce flat, simple shapes.

Embossing

The process of creating raised or recessed designs on the surface of a metal sheet. This is typically done for decorative purposes or for adding features such as logos or patterns.

Notching

The process of cutting small sections from the edge of a metal sheet to produce a notch or indentation. This is often done to create space for subsequent operations or to reduce weight.

Material

Brass

Aluminum

Steel

Stainless steel

Additional processes

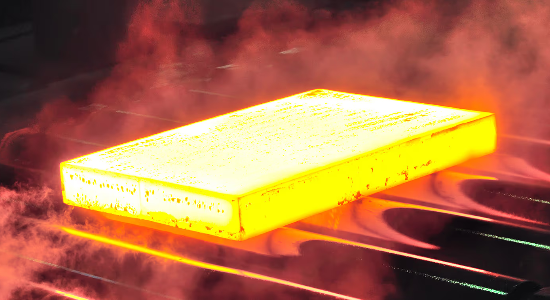

Heat Treatment: For parts that require enhanced durability, strength, or hardness, heat treatment processes such as annealing, tempering, and quenching can be applied to stamped metal. These processes modify the microstructure of the metal, improving its mechanical properties. Annealing involves heating the metal to a specific temperature and then slowly cooling it to relieve stress and increase ductility, making the part easier to work with. Tempering is typically applied to hardened steel parts to reduce brittleness while maintaining hardness and strength. Quenching, on the other hand, rapidly cools the metal (often in water or oil) to lock in hardness. These heat treatment processes are essential for ensuring that OEM metal stamping products meet the performance and durability requirements of industries such as automotive, aerospace, and industrial manufacturing. By tailoring the heat treatment process, manufacturers can optimize the stamped part for specific applications, enhancing both its longevity and reliability under demanding

Deburring and Finishing: To ensure smooth edges and flawless surfaces, we offer deburring and finishing services for OEM metal stamping products. These processes are essential for removing sharp edges, burrs, or any imperfections left after the stamping process. Deburring involves using various methods such as mechanical, manual, or automated processes to smooth out rough edges and prevent injuries or damage during handling and assembly. Finishing may include polishing, brushing, or bead blasting to improve the appearance and functionality of the part, giving it a clean, uniform surface. By incorporating these services, we not only enhance the aesthetic quality of the stamped components but also improve their performance, making them safer and more reliable for use in final applications. Whether for automotive, electronics, or industrial parts, our deburring and finishing services ensure that each stamped component meets the highest standards of quality and precision.