Product Description

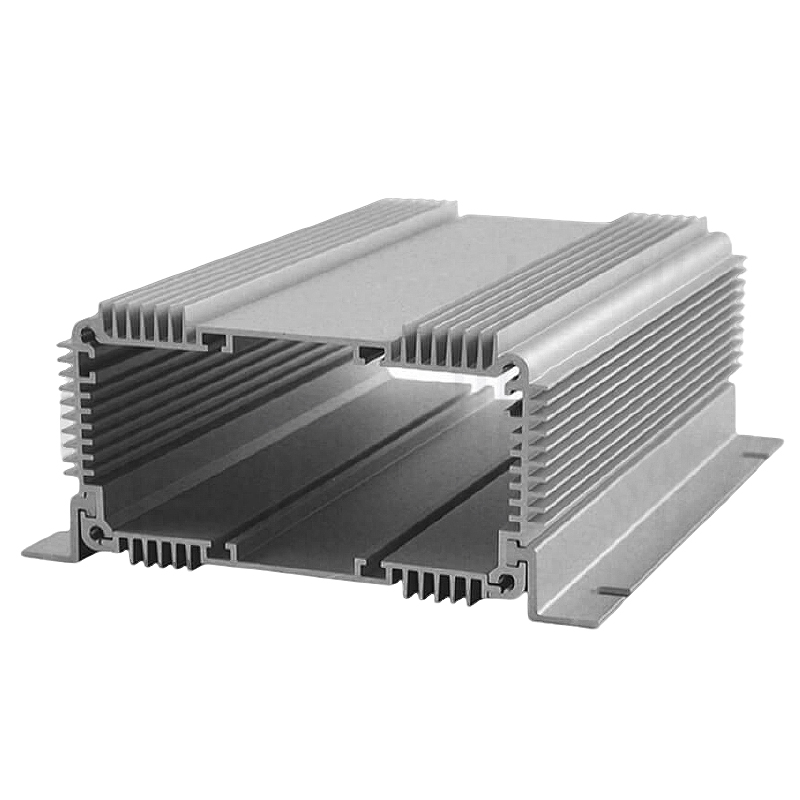

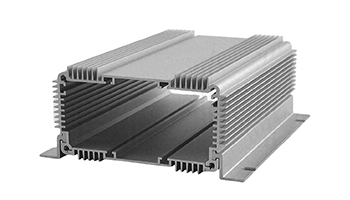

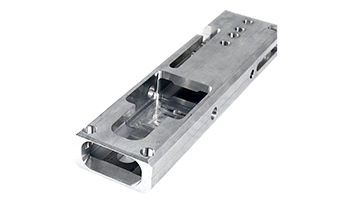

Our high-quality custom aluminum impact extrusion parts are the perfect combination of precision manufacturing and high-quality materials. High-quality aluminum alloy is selected as the raw material, which has the characteristics of light weight, high strength and strong corrosion resistance. The advanced impact extrusion process is adopted. During the processing, the aluminum material is impacted by a high-speed punch, so that the material flows and forms in the mold, which can efficiently produce parts with complex shapes and precise dimensions. This process not only greatly improves the utilization rate of materials, but also gives the parts excellent mechanical properties, ensuring that they can show excellent stability and reliability in various application fields, and meet the diverse customization needs of customers.

Product parameters

| Extruding Equipment | 600 -> 4000 Ton EXTRUDER MACHINES |

| Maximum extrusion size | 480x450 mm (WxH) |

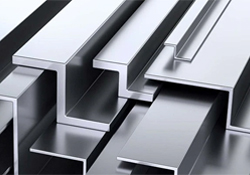

| Main Materials | Aluminum, aluminum alloy |

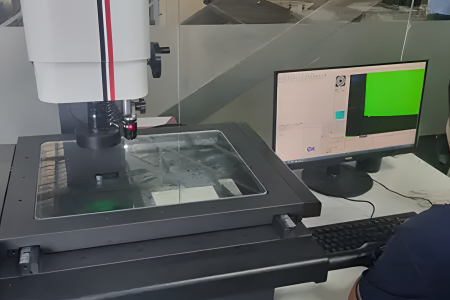

| Inspection | 100% before shipment |

Custom Process

1. Demand communication

2. Solution design

3. Quotation

4. Contract signing

5. Prepayment

6. Production delivery

7. Inspection and acceptance

8. Final payment settlement

Material

Quality Control

Quality standards are important guidelines to ensure that products meet specific requirements for safety, performance, and reliability. For companies like AMG Vietnam that export mechanical products abroad, adhering to strict quality standards is essential to maintaining customer trust and ensuring that products meet the high expectations of industries such as aerospace, automotive, medical devices, and electronics. These standards not only help ensure that products are manufactured correctly, but also help meet international regulations and certifications.

Processing capability

Company is one of the leading enterprises in the field of manufacturing products related to aluminum extrusion.

Extruding Equipment : 600 -> 4000 Ton EXTRUDER MACHINES

We can extrude with maximum dimensions up to: 480x450 mm (WxH)

With us we are always committed to:

Product quality: Specializing in providing extruded

aluminum products with high precision, beautiful

surface finish and good durability.

Professional team: We own experienced, highly skilled

partner companies in the aluminum extrusion

manufacturing industry.

Additional processes

Spray painting is to spray the paint evenly on the surface of the object after atomizing it with a spray gun. The paint forms a continuous film on the surface of the object. After drying and curing, this film adheres to the surface of the object to play a protective and decorative role. The atomization process can make the paint particles small and uniform, thereby ensuring the quality of the coating and making the surface smooth and uniform in color.