Product Description

RoboPlastik CNC – Custom engineering plastic solutions from Nylon, POM & PEEK, designed for high-precision CNC machining of high-quality robotic components. Our advanced materials are tailored for superior durability, heat resistance, and optimal mechanical performance, ensuring reliable functionality in demanding robotic applications.

Product parameters

| Type | Plastic CNC Turning Parts |

| Material | POM, ABS, Nylon, PEEK, Delrin, PTFE, Acrylic |

| Surface treatment | Polishing, Mirror Polished |

| Feature | Custom service |

| Sample | Samples Offered |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

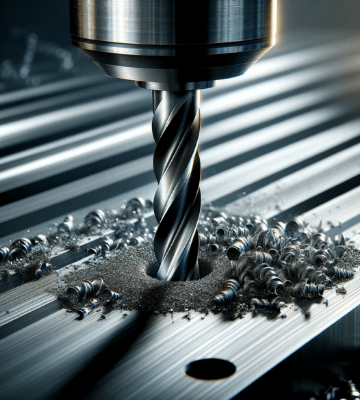

Drilling

Die casting

CNC machining

Material

Aluminum Alloy

Copper

Stainless Steel

Quality Control

Quality control for high-performance Nylon, POM, and PEEK components involves a rigorous process to ensure consistency, precision, and durability. Each material batch undergoes thorough inspection for uniformity in properties such as tensile strength, dimensional accuracy, and thermal resistance. Advanced metrology equipment is utilized to measure tolerances within microns, ensuring that every part meets exacting design specifications.

Processing capability

The processing capability of high-performance Nylon, POM, and PEEK involves advanced CNC machining techniques designed to achieve high precision, complex geometries, and tight tolerances. These materials exhibit excellent machinability, allowing for fine detailing and smooth surface finishes critical in high-performance applications. Specialized cutting tools and optimized machining parameters are employed to reduce tool wear and ensure dimensional stability. Multi-axis CNC milling, turning, and drilling enable the production of intricate parts with consistent accuracy.

Additional processes

Additional processes for high-performance Nylon, POM, and PEEK include a range of post-machining treatments to enhance material properties and ensure optimal performance in specialized applications. These processes may involve surface treatments such as anodizing, which improves wear resistance and surface hardness, or lubrication treatments to reduce friction and extend the lifespan of parts. For parts that require enhanced chemical resistance or UV stability, coatings or specialized finishes can be applied to provide protection against harsh environmental conditions.