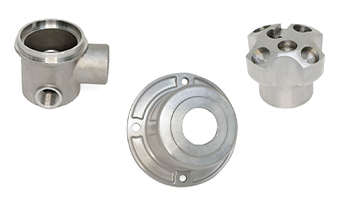

Product Description

Our CNC precision machining parts are characterized by high precision. They use advanced technology, are accurate in size, and are suitable for a variety of machines. From tough metals to special materials, they can be perfectly controlled, with outstanding durability, effectively improving equipment performance, and providing reliable protection for your production needs. They are the only choice for high-end manufacturing.

Product parameters

| Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals, stainless steel, Steel Alloys |

| Machining Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Process | Cnc Turning |

| Surface treatment | Customer's Request |

| Service | Customized OEM |

| Color | Customized Color |

| Size | Customized Size |

| OEM/ODM | Customized Product |

| Lead time | 5-7 days |

Custom Process

1. Send inquiries

2. Drawing or samples

3. Quotation

4. Customer confirmation

5. Places order and pays

6. Mass production

7. Test & packing

8. Shipping & confirmation

Process Type

Material

Stainless steel plate

Steel plate

Aluminum plate

Aluminum alloy plate

Quality Control

· Mitutoyo Digimatic Height Gage Standard Type 0-300mm

· Accuracy and resolution: Accuracy is ±0.02mm, and resolution can be switched between 0.01mm and 0.005mm.

· With coarse/fine feed switching and double-column structure, it can ensure measurement accuracy. It has dual preset, absolute/incremental value switching, zeroing, probe tip diameter compensation, positive/negative switching, data hold, data output, power switch, inch/millimeter conversion and other functions.

· Mitutoyo Crysta-Plus M443 is a manual air-floating CMM.

· Measuring range: X-axis 400mm, Y-axis 400mm, Z-axis 300mm.

· Resolution: 0.0005mm or 0.5μm.

· Accuracy: At 20°C, indication error μm, detection error μm, in line with ISO10360-2 standard.

· High-precision measurement: The scale for detecting the position of each axis is equipped with a high-precision Mitutoyo-specific linear encoder, which has high detection function and high-precision control function, and achieves high-precision measurement through various structures, controls, parts processing and assembly technologies.

The PV-30 profile projector is a precision optical metrology instrument that uses the principle of optical projection to project the profile or surface shape of the workpiece to be measured onto the viewing screen for measurement or comparison.

It has an excellent optical measurement system and can accurately project a magnified image with a profile magnification accuracy of 0.08% and a surface magnification accuracy of 0.12%.

It is usually equipped with an advanced data processing system, such as 3M DRO (DC 3000), which can achieve efficient data acquisition, processing and analysis, facilitate measurement and improve measurement efficiency.

Processing capability

TSUGAMI M08J-II Lathe with Fanuc OiT controller

Opens a new chapter in precision machining. With its high-precision mechanical structure, this machine tool has demonstrated its advantages in the field of rotary body machining. Whether it is a small shaft or a complex rotary part, it can be precisely carved. The Fanuc OiT controller ensures fast command response and smooth operation. The two work together to enable precision manufacturing industries such as aviation and electronics to efficiently produce high-quality parts.

Máy tiện TSUGAMI M08J-II với bộ điều khiển Fanuc OiT

It integrates advanced mechanical technology and FANUC precision control technology, and its high-rigidity body ensures stable processing. It can complete multiple processes such as drilling, tapping, and milling in one go. It can quickly and accurately shape complex precision hardware and small molds. It is widely used in 3C and medical device manufacturing fields, helping companies improve their competitiveness.

Fanuc Oi MF-driven VMC850II/P vertical machining center

Integrates high efficiency and precision. Its control system Fanuc Oi MF has excellent performance, convenient operation, and can accurately execute complex instructions. The machine tool has a stable structure and is suitable for processing various precision parts. It performs well in metal cutting, mold manufacturing and other fields, providing strong support for enterprises to improve production efficiency and ensure processing accuracy.