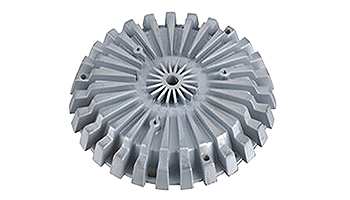

Product Description

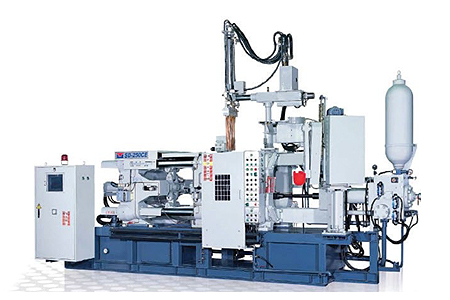

We focus on providing first-class OEM processing services, and our core product is metal casting customized radiators. Our professional team brings together industry elites to deeply explore your needs, starting from the source, and select high-quality metal materials that are suitable for a variety of working conditions; in the casting process, we use cutting-edge technology to carve every detail to ensure accurate dimensions and efficient heat dissipation structure; in terms of appearance, we can flexibly customize it according to your brand style and application scenarios.

Product parameters

| Design | We provide customized size & follow clients idea and designs |

| Materials | Brass, Steel, Metal, Copper, Aluminum, Iron, alloy (contact us if your required material is not listed above) |

| Length/ Size | We provide customized size & follow clients idea and designs |

| Advantage | 1.Quality assurance 2.Fast delivery 3.Affordable price 4.Timely response |

Custom Process

1.Contact customer service

2.Confirm specifications

3.Pay deposit

4.Arrange production

5.Quality inspection

6.Pay the final payment

7.Arrange delivery

8.Confirm receipt of goods

Material

Steel

Aluminum

Iron

Stainless steel

Quality Control

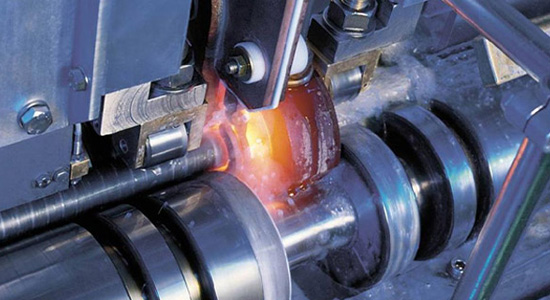

In the field of precision casting, quality control is our lifeline. From the strict selection of raw materials, each batch is tested in multiple ways to ensure purity and performance; to the fine control of the casting process, temperature, pressure, time and other parameters are monitored in real time, and no deviation is allowed. The mold is repeatedly calibrated to ensure accurate dimensions. After molding, the appearance, size, and internal structure are fully non-destructively inspected and measured with high-precision measuring tools. We check every level to deliver high-quality, zero-defect precision casting products to you.

Processing capability

TBD has excellent processing capabilities. In terms of precision control, with advanced equipment and exquisite craftsmanship, the dimensional accuracy can reach micron level, and the form and position tolerances are extremely small, ensuring that the product perfectly fits the design. Complex structures can also be achieved, and parts with fine cavities and ultra-thin walls can be manufactured. In terms of materials, it covers all kinds of metals to meet diverse needs. From tiny precision parts to large industrial components, the processing size span is large. Small batch customization can be flexibly adjusted, and large-scale production can also be completed efficiently, providing high-quality precision castings for various industries.

Additional processes

Quenching: Heating the casting to above the critical temperature, keeping it warm for a certain period of time and then cooling it rapidly to improve the hardness and strength of the casting. For example, in precision casting of molds, quenching treatment can improve the wear resistance and service life of the mold.