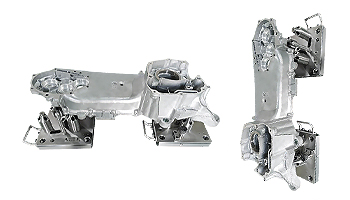

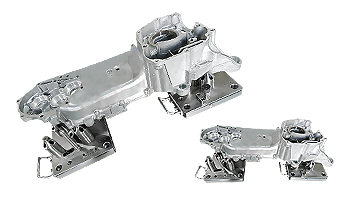

Product Description

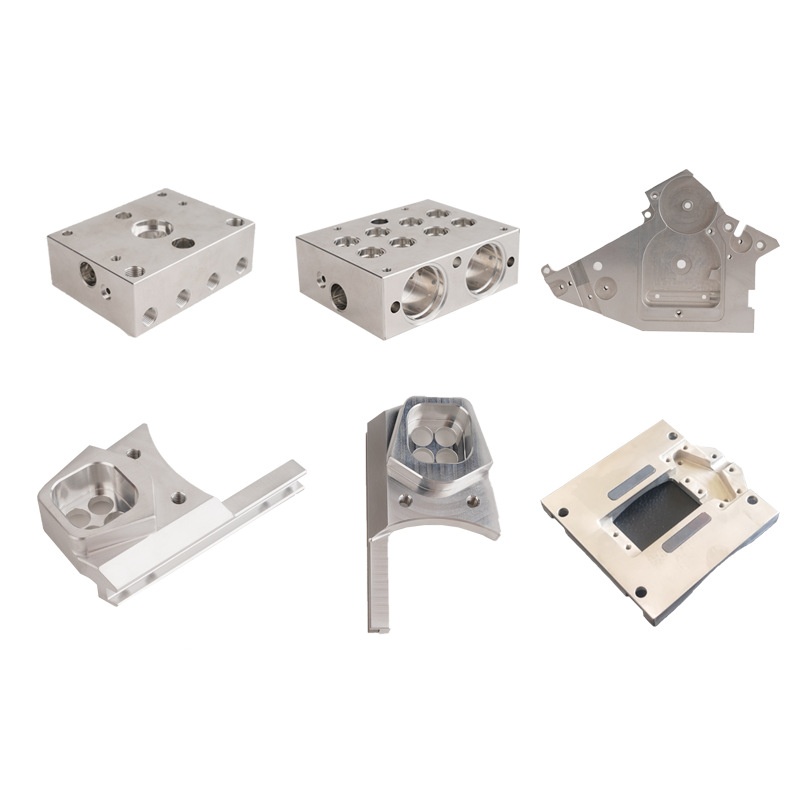

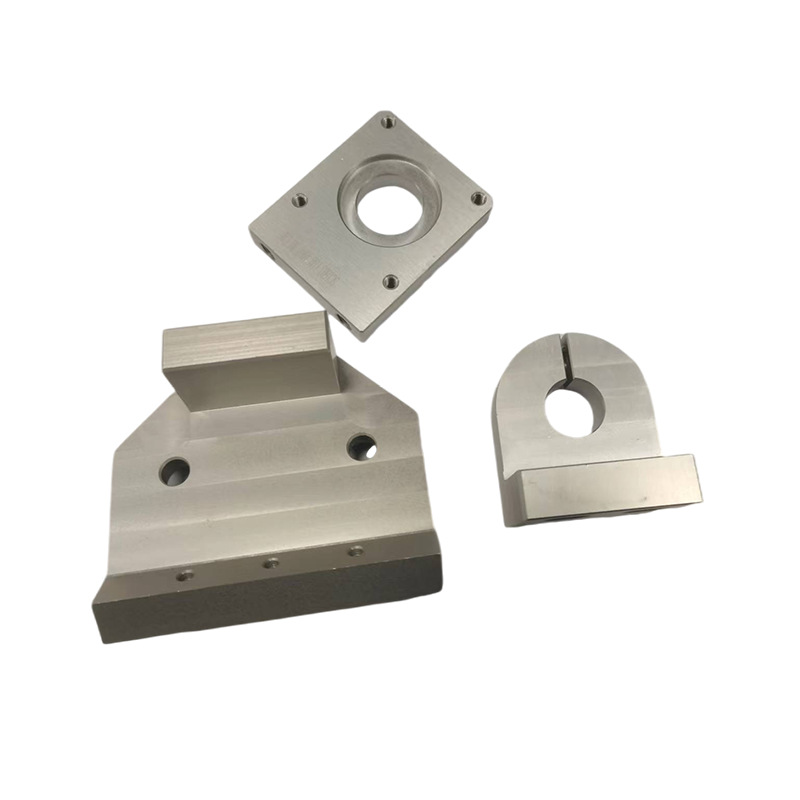

Our services include broaching, drilling, laser machining, milling, turning, and other machining services, making us a one-stop-shop for all your machining needs.

CNC machining services ensure precise and accurate results, with a tolerance of 0.01- +/-0.005mm, suitable for high-precision applications.

Product parameters

| Material | Aluminum, Brass, Bronze, Copper, Hardened Metal, Pre-cious Metal, Stainless Steel, Steel Alloy |

| Process | CNC Machining |

| Heat treatment | Annealing, Normalizing , Nitriding, Tempering , Carbonitriding |

| Tolerance | 0.01- +/-0.005mm |

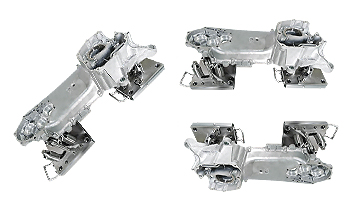

| Application | Industrial Equipment parts |

| Service | Customized OEM CNC Machining |

| MOQ | all Orders Accepted |

| QC Control | 100% QC Steps Inspection |

| Drawing Format | 2D/(PDF/CAD)3D(IGES/STEP) |

| Package | Standard Carton Or Plastic Tray, Sponge Tray, CardboardTray, etc., Can Be Customized According To CustomerRequirements |

| Processing Type | Broaching, DRILLING, Laser Machining, Milling, Turning, Wire EDM |

Custom Process

1. Send inquiries

2. Drawing or samples

3. Quotation

4. Customer confirmation

5. Places order and pays

6. Mass production

7. Test & packing

8. Shipping & confirmation

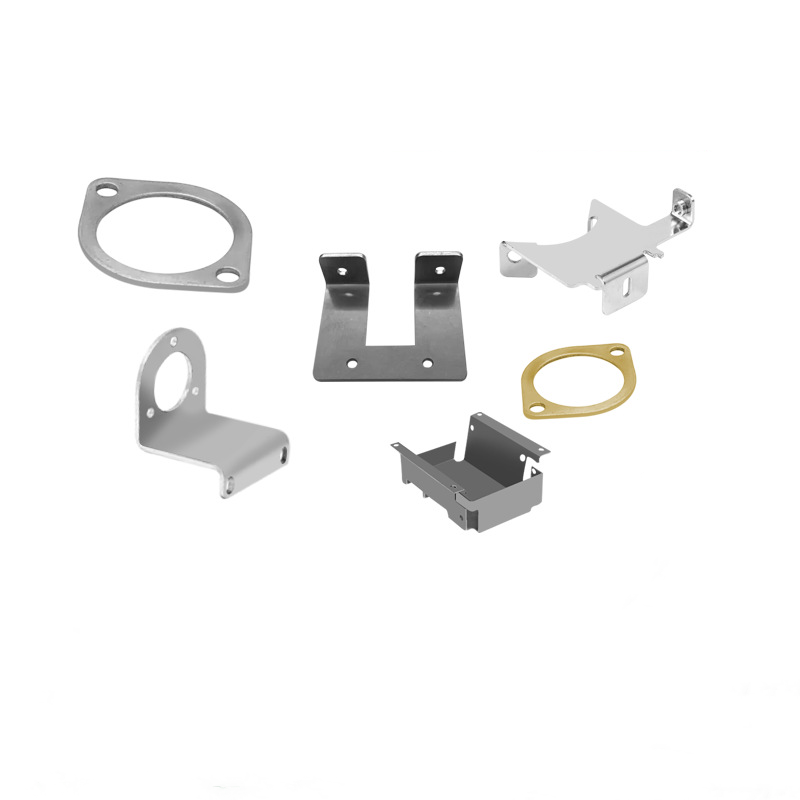

Process Type

Material

Stainless Steel Sheet

Iron carbon sheet

Galvanized steel sheet

Carbon Steel Sheet

Quality Control

The roughness measuring machine model LAB-20200106-01 is an instrument used to measure the surface roughness of an object.

High-precision measurement: It uses advanced sensing technology and measurement algorithms to accurately measure the roughness value of the surface of an object. It can measure a variety of roughness parameters, such as arithmetic mean roughness Ra, maximum height Rz, average height Ry, etc.

The PV-30 profile projector is a precision optical metrology instrument that uses the principle of optical projection to project the profile or surface shape of the workpiece to be measured onto the viewing screen for measurement or comparison.

It has an excellent optical measurement system and can accurately project a magnified image with a profile magnification accuracy of 0.08% and a surface magnification accuracy of 0.12%.

It is usually equipped with an advanced data processing system, such as 3M DRO (DC 3000), which can achieve efficient data acquisition, processing and analysis, facilitate measurement and improve measurement efficiency.

The roughness measuring machine model LAB-20200106-01 is an instrument used to measure the surface roughness of an object.

High-precision measurement: It uses advanced sensing technology and measurement algorithms to accurately measure the roughness value of the surface of an object. It can measure a variety of roughness parameters, such as arithmetic mean roughness Ra, maximum height Rz, average height Ry, etc.

Processing capability

TSUGAMI M08J-II Lathe with Fanuc OiT controller

Opens a new chapter in precision machining. With its high-precision mechanical structure, this machine tool has demonstrated its advantages in the field of rotary body machining. Whether it is a small shaft or a complex rotary part, it can be precisely carved. The Fanuc OiT controller ensures fast command response and smooth operation. The two work together to enable precision manufacturing industries such as aviation and electronics to efficiently produce high-quality parts.

Fanuc Oi MF-driven VMC850II/P vertical machining center

Integrates high efficiency and precision. Its control system Fanuc Oi MF has excellent performance, convenient operation, and can accurately execute complex instructions. The machine tool has a stable structure and is suitable for processing various precision parts. It performs well in metal cutting, mold manufacturing and other fields, providing strong support for enterprises to improve production efficiency and ensure processing accuracy.

It integrates advanced mechanical technology and FANUC precision control technology, and its high-rigidity body ensures stable processing. It can complete multiple processes such as drilling, tapping, and milling in one go. It can quickly and accurately shape complex precision hardware and small molds. It is widely used in 3C and medical device manufacturing fields, helping companies improve their competitiveness.