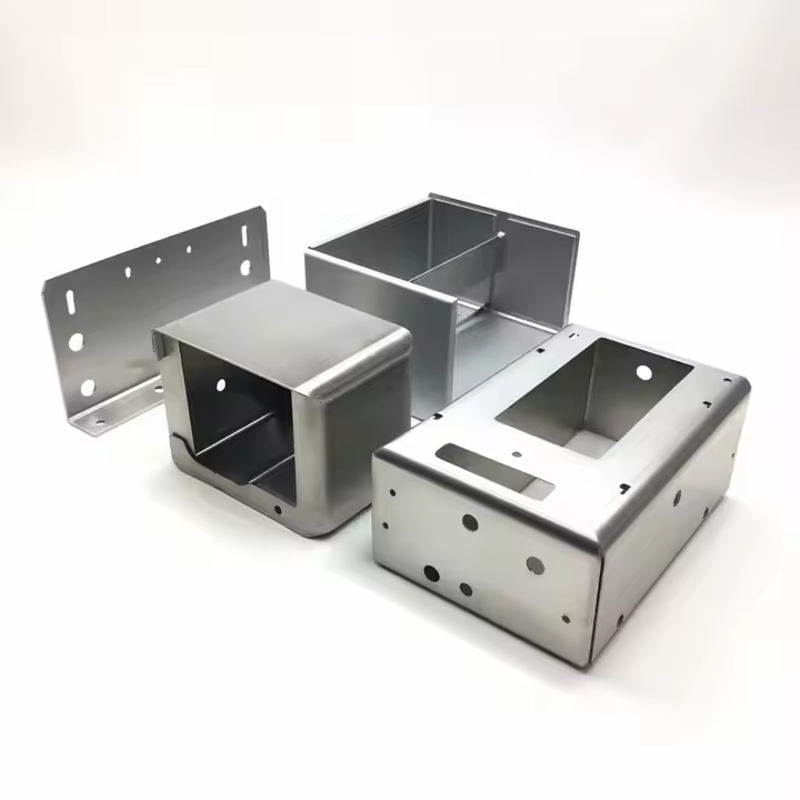

Product Description

CNC machining parts in custom aluminum provide precision and versatility for a variety of applications. Using advanced CNC technology, these parts are manufactured to meet exact specifications with tight tolerances. Aluminum’s lightweight yet durable properties make it ideal for industries like aerospace, automotive, and electronics. The process supports intricate designs, ensuring accuracy and fine detailing. Customization options include surface finishes, such as anodizing or polishing, to meet specific needs. CNC machining delivers high-quality, cost-effective parts with quick turnaround times.

Product parameters

| List | Details |

|---|---|

| Product name | CNC Machining Parts |

| Material Capabilities | Material Capabilities |

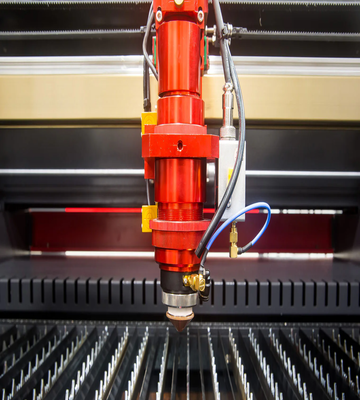

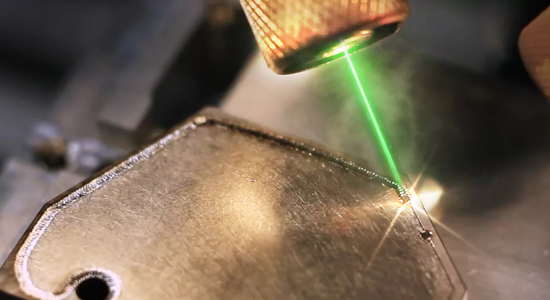

| Type | Broaching, DRILLING, Etching / Chemical Machining, Laser Machining, Milling, Other Machining Services, Turning, Wire EDM, Rapid Prototyping |

| Keyword | CNC Machining Large Panel Parts |

| Feature | Precision Durable |

| Service | OEM ODM Service |

| Quality | 100% Tested |

| PAYMENT | T/T 30%Deposit 70%Before Delivery |

Custom Process

1.Send inquiries

2.Drawings or samples

3. Quotation

4.Customer confirmation

5. Places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

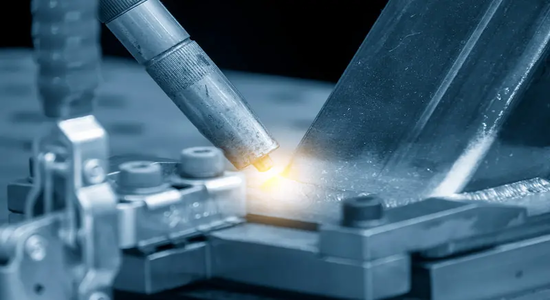

Process Type

Turning

Milling & Drilling

Turning

Material

Aluminum Sheet

Brass Sheet

Copper Sheet

Quality Control

QC of CNC machining parts in custom aluminum involves precise measurement and inspection of dimensions to ensure tight tolerances. Surface finishes are checked for smoothness, consistency, and quality. Material properties are verified to meet specifications for strength and durability. Functional tests confirm the part performs as intended in its application. Each part undergoes detailed inspection for any defects, such as burrs or deformities. Final verification ensures compliance with customer requirements and industry standards.

Processing capability

CNC machining parts in custom aluminum offer high precision and flexibility for a variety of applications. The process supports complex geometries, intricate designs, and tight tolerances, ensuring accuracy in every part. Aluminum’s lightweight nature makes it ideal for industries like aerospace, automotive, and electronics. CNC machines can perform milling, turning, drilling, and tapping, allowing for the creation of detailed components. The material can be machined into different shapes, including flat, curved, or multi-dimensional forms.

Additional processes

Surface finishes such as anodizing, polishing, and bead blasting enhance the appearance and durability of aluminum parts. CNC technology allows for rapid prototyping and small-batch production, reducing lead times. It also supports large-scale manufacturing with consistent quality across all parts. Customization options include threading, slotting, and engraving, to meet specific client needs. The process minimizes material waste, optimizing both cost and production efficiency. CNC machining ensures repeatability, with each part produced to the exact same standards. It’s ideal for creating lightweight, durable components with high-performance specifications.