Product Description

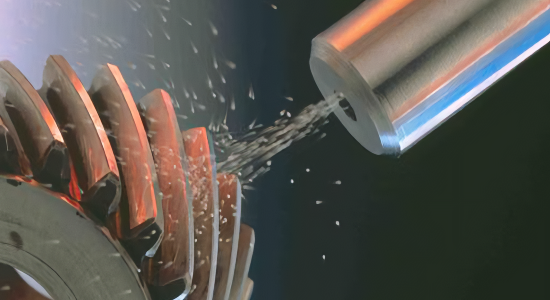

CNC micro milling, drilling, and turning services for stainless steel, brass, and copper materials, utilizing advanced Wire EDM technology to ensure high-precision parts with complex geometries. Our customizable solutions cater to various industries, including automotive, aerospace, electronics, and medical, where precision and durability are critical.

Product parameters

| Product name | Custom CNC machining |

| keyword | Precision CNC milling processing |

| Material | Aluminum/brass/plastic/copper/titanium alloy/iron/stainless steel/steel alloy |

| Equipment | Three-axis, four-axis, five-axis machining center |

| Process | CNC milling;CNC turning |

| Application | Industrial equipment |

| Sheet format | 2D/(PDF/DWG)3D(IGES/STEP) |

| Surface treatment | Anodizing, electroplating |

| Serve | OEM customization |

Custom Process

1. Customer inquiry

2.Send drawing/sample

3. Mold making

4. Machine processing

5. Quality Control

6. Packing

7. Transportation

8. After-sale support

Process Type

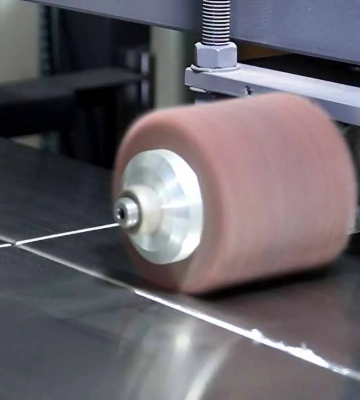

Deburing

Die Casting

Polishing

Material

Aluminum Alloy

Zinc Alloy

Alloy Steel

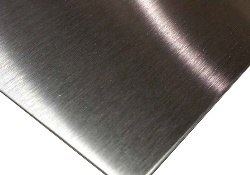

Stainless Steel

Quality Control

Quality control for our Custom CNC Prototype Services, including micro milling and drilling, is conducted through a rigorous multi-stage inspection process to ensure each part meets exact specifications. We utilize advanced measuring tools such as coordinate measuring machines (CMM), high-precision calipers, and microscopes to verify dimensions, surface finish, and tolerances. Our team is trained to perform in-process checks during production and final inspections to guarantee consistency, accuracy, and defect-free results.

Processing capability

Our Custom CNC Prototype Services for micro milling and drilling offer exceptional processing capability for a wide range of materials, including stainless steel, brass, copper, and specialized alloys. We can produce parts with intricate geometries, tight tolerances, and high surface finish precision, ensuring accuracy down to the micron level. Our equipment supports both low-volume prototyping and high-volume production, delivering consistent quality across complex designs.

Additional processes

In addition to micro milling and drilling, our Custom CNC Prototype Services offer a variety of additional processes to enhance the functionality and precision of your parts. These include Wire EDM cutting for intricate shapes and fine detailing, surface grinding for superior finish and flatness, and precision turning for cylindrical components. We also provide secondary processes such as deburring, polishing, and heat treatment to improve part performance and durability.