Product Description

Our services include rapid prototyping, micro-machining, and customized surface treatment, allowing us to provide tailored solutions for each customer's specific project, including those with unique requirements from a user.

Product parameters

| Milling enclosure | 1.300 x 670 x 625 mm |

| Horizontal milling enclosure | 800 x 750 x 850 mm |

| Turning dimensions | D481 * L1.275 mm |

| Tolerance | 0.02 to 0.10 mm |

| Raw material | Aluminum, Titanium, Copper, Stainless Steel, Steel Alloy, Inconel, cast iron |

| Process | CNC Turning, CNC Milling, CNC Machining, Grinding, EDM Wire Cutting |

| Service | One Stop Service. Machining-assembly |

| Size | Size Customized |

| File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF etc. |

| MOQ | 10pcs |

| Service Project | To provide production and technical service, mould development and processing, etc |

Custom Process

1. Send inquiries

2. Drawing or samples

3. Quotation

4. Customer confirmation

5. Places order and pays

6. Mass production

7. Test & packing

8. Shipping & confirmation

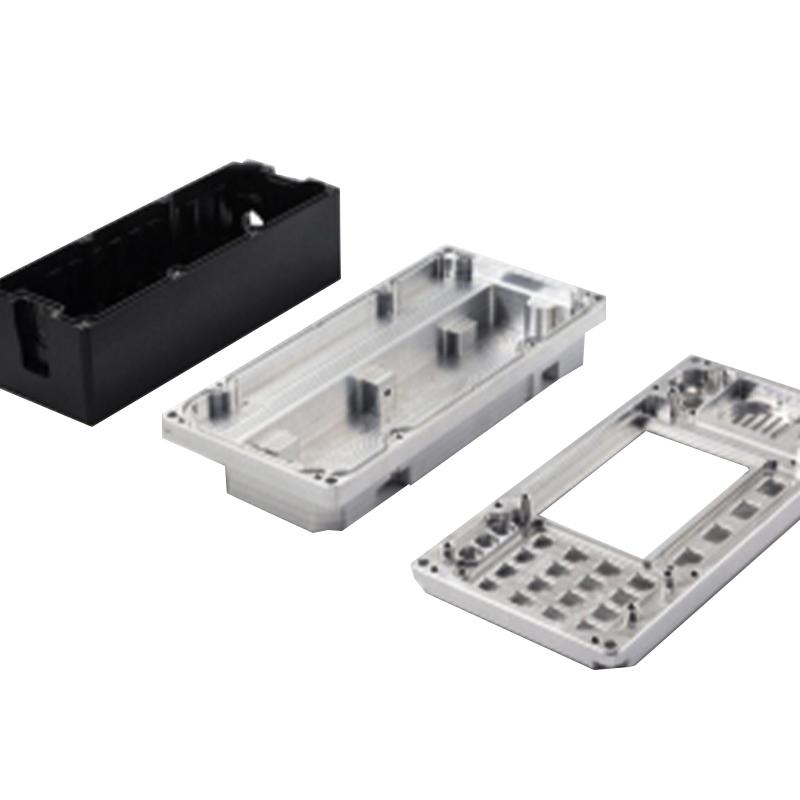

Process Type

Tooling & Molding

Plastic injection & die casting molds,plastic molding, printing,assembly

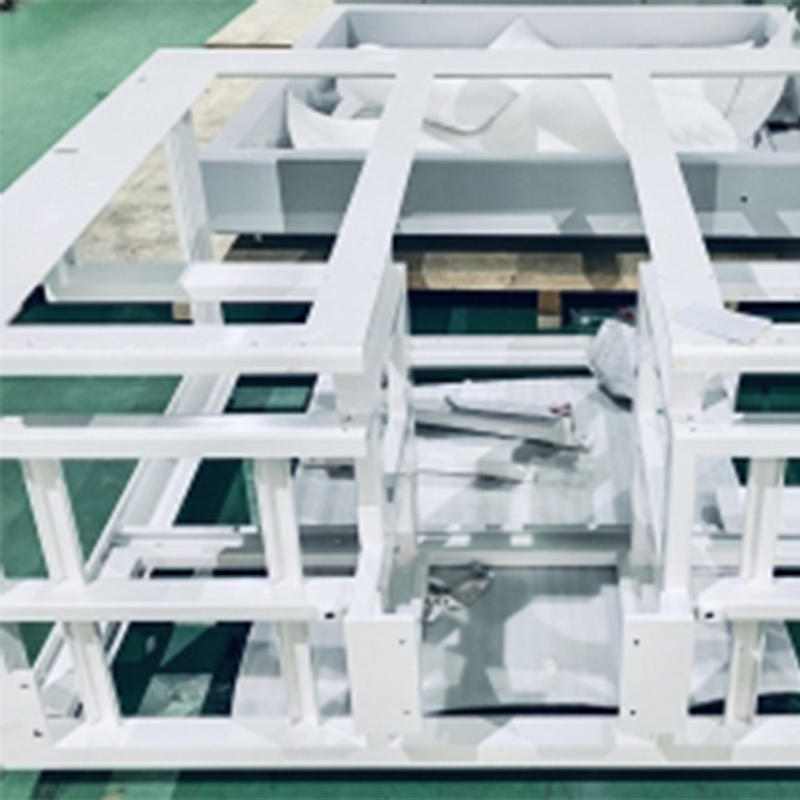

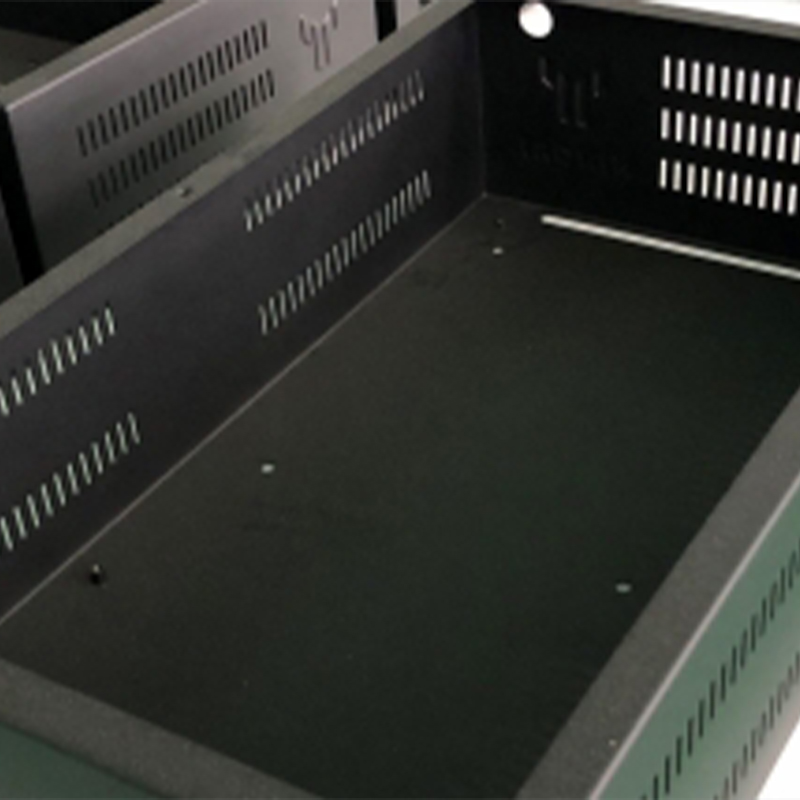

Sheet Metal

Sheet Metal &Frame Fabrication, Surface Treatment

Precision Machining

One-off to mass production Anodizing & coating

Material

Aluminum

Copper

Stainless Steel

Steel Alloy

Quality Control

CMM machine stands for Coordinate Measuring Machine. It is a tool that can measure the dimensions of machine/tool parts using coordinate technology. The dimensions available for measurement include height, width and depth in X, Y and Z axis. The physical geometry and dimensions of the object are measured by a contact probe mounted on the moving axis of the machine.CMM has better speed and accuracy to measure parts repeatedly. It can also increase productivity while reducing the possibility of errors in the measurement process.

Vision measuring machines can recognize positioned workpieces and automatically load the corresponding program. Coordinate systems can be automatically created, and autofocus and automatic lighting settings can be achieved. This not only reduces the operator's workload, but also makes the measurement process free from operator influence and achieves the best repeatability. Whether it is used in automotive, electronics or plastic processing, vision measuring machines are particularly suitable for accurately detecting distance, radius or angle dimensions.

Processing capability

The vertical machining center, with its vertically arranged spindle, shows unique processing advantages. With three- and four-axis linkage functions, it can accurately process complex contours. With high-precision ball screws, the positioning accuracy can reach ±0.003mm. The worktable has a strong load-bearing capacity and can stably process workpieces of various sizes. It is particularly good at processing plate and disc parts, and is widely used in mold manufacturing, electronic equipment production and other industries, providing efficient and reliable processing solutions for precision manufacturings

The vertical machining center, with its vertically arranged spindle, shows unique processing advantages. With three- and four-axis linkage functions, it can accurately process complex contours. With high-precision ball screws, the positioning accuracy can reach ±0.003mm. The worktable has a strong load-bearing capacity and can stably process workpieces of various sizes. It is particularly good at processing plate and disc parts, and is widely used in mold manufacturing, electronic equipment production and other industries, providing efficient and reliable processing solutions for precision manufacturing.

CNC precision surface grinding grinds the workpiece surface with a high-speed rotating grinding wheel to achieve high-precision processing. With advanced CNC systems, the flatness can reach ±0.001mm and the surface roughness can reach Ra0.05μm. It can process a variety of metal and non-metal materials, such as hardened steel, ceramics, etc. Whether it is a flat surface, a cylindrical surface or a complex molding surface, it can be accurately ground. It can effectively eliminate material surface defects, provide ultra-precision surface quality for products, and meet high-end manufacturing needs.

Additional processes

We offers painting service with various materials for industry application.

Powder coating line with 02 separate treatment processes for aluminum and steel, applied Chromium (III) for Aluminum and Zinc phosphate for steel, both be passed FDA, RoHS compliance.

Spray painting offers to products with complicated texture requirement, multiple coatings.

Anodic coating type II, class 1, 2 with multi color applicable, be made between 5 and 22μm, this is highly effective solution for aluminum surface protection.

Anodic coating type III, be made between 25 and 40μm.

Chromate conversion coating, is also called Alodine coating, Irridite coating. Curently producing several types as CT3796, CT3700 or Yellow Alodine,…

Silk screen printing is widely used in sheet metal forming, can be applied in a variety of color and on flat or curved surfaces.

Sandblasting is one of solution to prepare surface of aluminum before painting or anodizing.