Mô tả sản phẩm

Dịch vụ tiện và phay CNC tùy chỉnh OEM của chúng tôi đáp ứng các yêu cầu cụ thể, cho phép tạo ra các bộ phận bằng thép không gỉ, nhôm, đồng thau và các bộ phận kim loại khác độc đáo với các tùy chọn về kích thước và màu sắc tùy chỉnh.

Thông số sản phẩm

| Dung sai | 0.02 đến 0.10 mm |

| Nguyên liệu | Nhôm, Titan, Đồng, Thép không gỉ, Hợp kim thép, Inconel, gang |

| Quy trình | Tiện CNC, Phay CNC, Gia công CNC, Mài, Cắt dây EDM |

| Dịch vụ | Dịch vụ một cửa. Gia công-lắp ráp |

| Kích thước | Kích thước tùy chỉnh |

| Định dạng tệp | Solid Works, Pro/Engineer, AutoCAD(DXF,DWG), PDF,TIF, v.v. |

| MOQ | 10 chiếc |

| Dự án dịch vụ | Cung cấp dịch vụ sản xuất và kỹ thuật, phát triển và gia công khuôn mẫu, v.v. |

| Vỏ phay | 1.300 x 670 x 625 mm |

| Vỏ phay ngang | 800 x 750 x 850 mm |

| Kích thước tiện | D481 * L1.275 mm |

Quy trình tùy chỉnh

1. Gửi yêu cầu

2. Bản vẽ hoặc mẫu

3. Báo giá

4. Xác nhận của khách hàng

5. Đặt hàng và thanh toán

6. Sản xuất hàng loạt

7. Kiểm tra trước khi đóng gói

8. Vận chuyển và xác nhận

Loại quy trình

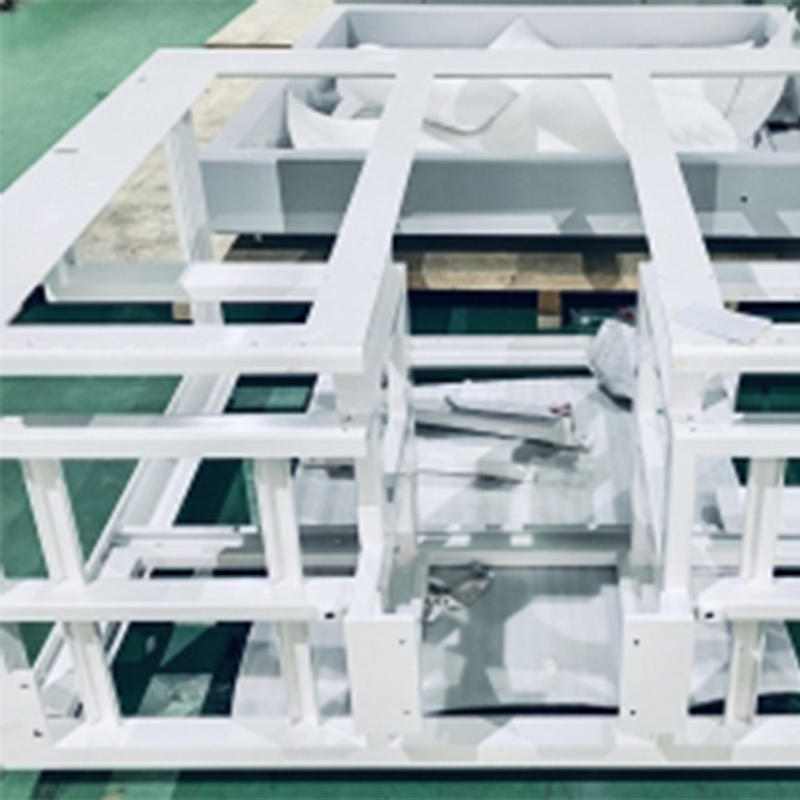

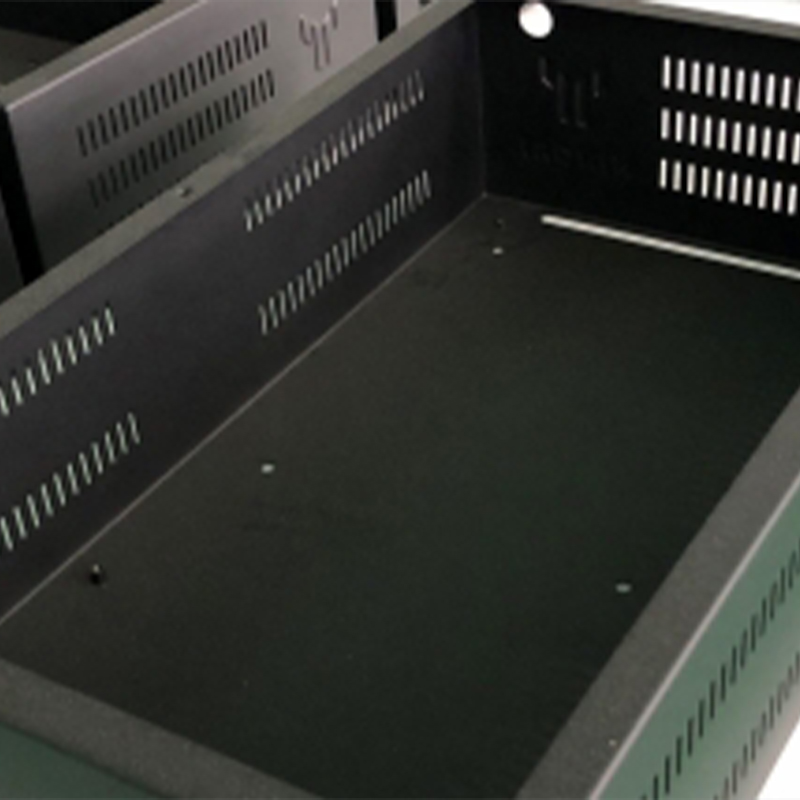

Tấm kim loại

Chế tạo khung và tấm kim loại, xử lý bề mặt

Công cụ & Khuôn mẫu

Khuôn ép nhựa & khuôn đúc khuôn mẫu, khuôn nhựa, in ấn, lắp ráp

Gia công chính xác

Anodizing & phủ từ sản xuất hàng loạt một lần

Chất liệu

Titan

Đồng

Thép không gỉ,

Hợp kim thép

Kiểm soát chất lượng

Máy đo thị giác có thể nhận dạng phôi gia công được định vị và tự động tải chương trình tương ứng. Hệ thống tọa độ có thể được tự động tạo ra và có thể đạt được chế độ tự động lấy nét và cài đặt ánh sáng tự động. Điều này không chỉ làm giảm khối lượng công việc của người vận hành mà còn giúp quá trình đo lường không bị ảnh hưởng bởi người vận hành và đạt được khả năng lặp lại tốt nhất. Cho dù được sử dụng trong ô tô, điện tử hay chế biến nhựa, máy đo thị giác đặc biệt phù hợp để phát hiện chính xác các kích thước khoảng cách, bán kính hoặc góc.

Máy CMM là viết tắt của Coordinate Measurement Machine (Máy đo tọa độ). Đây là một công cụ có thể đo kích thước của các bộ phận máy móc/công cụ bằng công nghệ tọa độ. Các kích thước có thể đo bao gồm chiều cao, chiều rộng và chiều sâu theo trục X, Y và Z. Hình dạng vật lý và kích thước của vật thể được đo bằng đầu dò tiếp xúc gắn trên trục chuyển động của máy. CMM có tốc độ và độ chính xác tốt hơn để đo các bộ phận nhiều lần. Nó cũng có thể tăng năng suất đồng thời giảm khả năng xảy ra lỗi trong quá trình đo.

Khả năng xử lý

Mài bề mặt chính xác CNC mài bề mặt phôi bằng bánh mài quay tốc độ cao để đạt được độ chính xác cao. Với hệ thống CNC tiên tiến, độ phẳng có thể đạt ±0,001mm và độ nhám bề mặt có thể đạt Ra0,05μm. Nó có thể xử lý nhiều loại vật liệu kim loại và phi kim loại, chẳng hạn như thép cứng, gốm sứ, v.v. Cho dù là bề mặt phẳng, bề mặt hình trụ hay bề mặt đúc phức tạp, nó đều có thể được mài chính xác. Nó có thể loại bỏ hiệu quả các khuyết tật bề mặt vật liệu, cung cấp chất lượng bề mặt cực kỳ chính xác cho sản phẩm và đáp ứng nhu cầu sản xuất cao cấp.

Thông qua liên kết của các trục X, Y và Z, nó thể hiện khả năng xử lý tuyệt vời. Với sự hỗ trợ của hệ thống CNC tiên tiến, độ chính xác định vị đạt ±0,005mm và nó có thể phay chính xác các đường viền hai chiều và ba chiều phức tạp. Nó có thể xử lý nhiều loại vật liệu, từ kim loại đến nhựa kỹ thuật. Bàn làm việc có nhiều kích cỡ khác nhau để thích ứng với các phôi có kích thước khác nhau. Với dao phay quay tốc độ cao và hiệu suất cắt cao, nó được sử dụng rộng rãi trong sản xuất máy móc, chế tạo mô hình và các lĩnh vực khác để tạo ra các bộ phận có độ chính xác cao cho nhiều sản phẩm khác nhau.

Gia công chính xác CNC EDM dựa trên việc nung chảy hoặc khí hóa vật liệu ở nhiệt độ cao bằng cách phóng điện để đạt được gia công. Với sự trợ giúp của công nghệ CNC tiên tiến, nó có thể đạt được độ chính xác cao ±0,002mm. Nó phù hợp với các vật liệu khó cắt như hợp kim chịu nhiệt và hợp kim titan. Nó có thể gia công các khoang và lỗ có hình dạng phức tạp. Phương pháp gia công này không có lực cắt cơ học, có thể giảm biến dạng và có thể gia công các vật liệu khó gia công bằng các phương pháp truyền thống, cung cấp một giải pháp đáng tin cậy cho sản xuất chính xác.

Quy trình khác

Chúng tôi cung cấp dịch vụ sơn với nhiều loại vật liệu khác nhau cho ứng dụng công nghiệp.

Dây chuyền sơn tĩnh điện với 02 quy trình xử lý riêng biệt cho nhôm và thép, ứng dụng Crom (III) cho Nhôm và Kẽm phosphat cho thép, cả hai đều đạt tiêu chuẩn FDA, RoHS.

Sơn phun cung cấp cho các sản phẩm có yêu cầu về kết cấu phức tạp, nhiều lớp phủ.

Lớp phủ anot loại II, loại 1, 2 có nhiều màu áp dụng, được tạo ra từ 5 đến 22μm, đây là giải pháp hiệu quả cao để bảo vệ bề mặt nhôm.

Lớp phủ anot loại III, được tạo ra từ 25 đến 40μm.

Lớp phủ chuyển đổi cromat, còn được gọi là lớp phủ Alodine, lớp phủ Irridite. Hiện đang sản xuất một số loại như CT3796, CT3700 hoặc Yellow Alodine,…

In lụa được sử dụng rộng rãi trong định hình kim loại tấm, có thể được áp dụng với nhiều màu sắc và trên bề mặt phẳng hoặc cong.

Phun cát là một trong những giải pháp để chuẩn bị bề mặt nhôm trước khi sơn hoặc anot hóa.