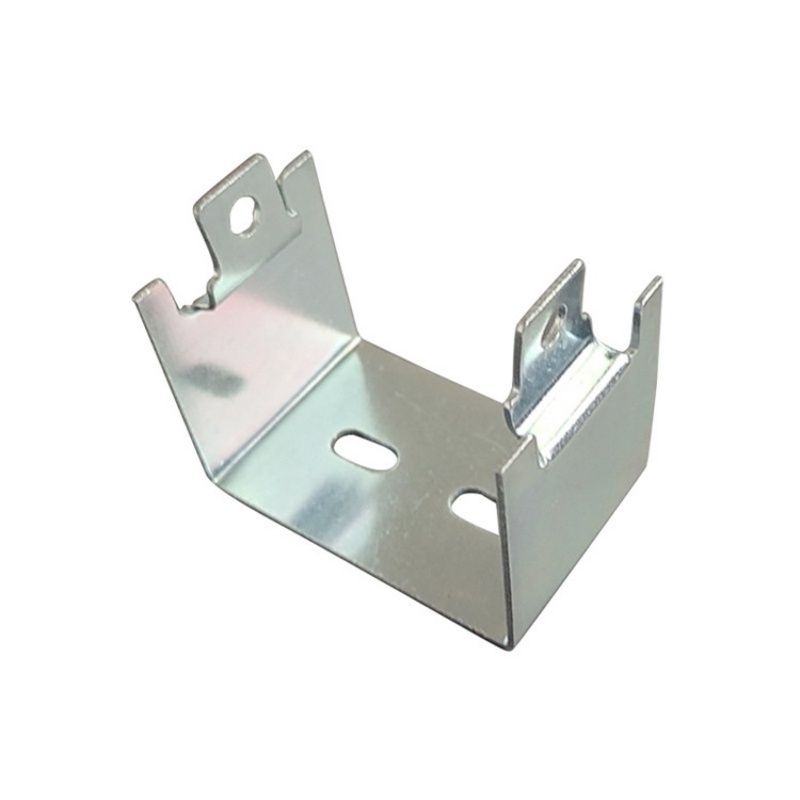

Product Description

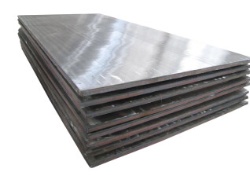

OEM metal parts are custom made with high-quality materials such as stainless steel and aluminum, ensuring superior durability and strength for various applications. These parts are ideal for mobile phones, electronic devices, tool cases, and other precision-required industries. Our advanced manufacturing processes, including stamping, machining, and surface treatments, guarantee high performance and a perfect fit for each component.

Product parameters

| MOQ | 1000 | |||

| Type | Other | |||

| Material | Stainless steel | |||

| Product name | Stamping Parts | |||

Custom Process

1. Inquiry

2. Mold design

3. Mold making

4. Stamping

5. Dimension inspection

6. Visual inspection

7. Package

8. Transportation

Process Type

Blanking

The process of cutting out a piece from a larger sheet of metal. The cut piece, called a "blank," is separated from the rest of the material. This is often the first step in the production of parts and is used to produce flat, simple shapes.

Embossing

The process of creating raised or recessed designs on the surface of a metal sheet. This is typically done for decorative purposes or for adding features such as logos or patterns.

Notching

The process of cutting small sections from the edge of a metal sheet to produce a notch or indentation. This is often done to create space for subsequent operations or to reduce weight.

Material

Brass

Aluminum

Steel

Stainless steel

Quality Control

Quality control of OEM metal components is a crucial part of our manufacturing process, ensuring that every part meets the highest standards of performance and durability. From the selection of raw materials to the final inspection, we apply rigorous testing and inspection procedures to guarantee dimensional accuracy, material integrity, and surface quality. Our experienced quality control team utilizes advanced measurement tools and equipment to identify and correct any potential defects before the parts are delivered.

Processing capability

Our processing capability for OEM metal components encompasses a wide range of advanced techniques to produce high-precision parts. Using cutting-edge technologies such as stamping, CNC machining, laser cutting, and forming, we are able to create complex geometries and intricate designs with tight tolerances. We work with a variety of materials, including stainless steel, aluminum, and other alloys, ensuring that each component meets the specific requirements of the client.

Additional processes

In addition to core manufacturing processes, we offer a range of supplementary services for OEM metal components to ensure they meet the highest standards of functionality and appearance. These include surface treatments such as anodizing, powder coating, electroplating, and passivation, which enhance corrosion resistance and improve aesthetics. We also provide heat treatment for increased strength, as well as welding, assembly, and packaging services to deliver fully integrated and ready-to-use components.