Product Description

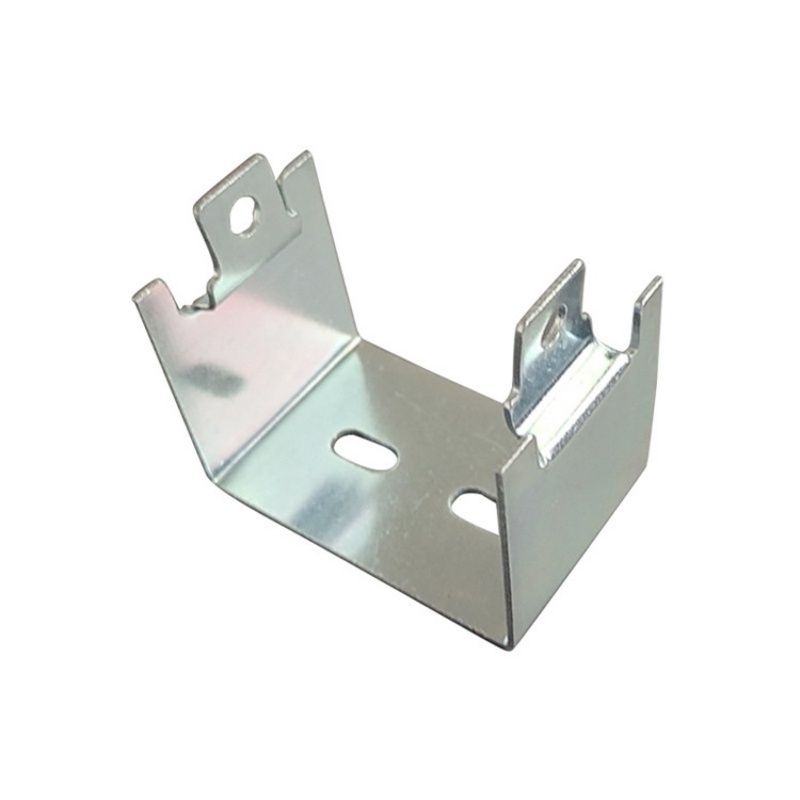

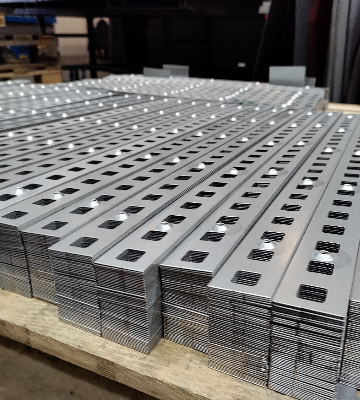

Custom stainless steel and aluminum sheet metal stamping works are produced to meet specific designs, utilizing advanced technology to ensure high precision and consistency. These stamping processes allow for intricate and complex shapes, making them ideal for a wide range of industries, including automotive, aerospace, electronics, and construction.

Product parameters

| SIZE | 1/4 3/8 1/2 5/8 3/4 |

| Material | Aluninum |

| MOQ | 10PCS |

| Sample: | Available |

| Package: | 6PCS in a small bag |

| Material: | Viton,Plastic |

Custom Process

1. Inquiry

2. Mold design

3. Mold making

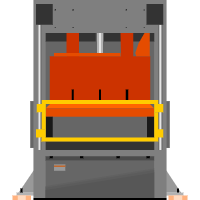

4. Stamping

5. Dimension inspection

6. Visual inspection

7. Package

8. Transportation

Process Type

Punching

Involves creating holes or cutouts in the workpiece using a punch and die set. The punch forces the material into the die to create the desired hole shape.

Trimming

Involves removing excess material from the edges of a stamped part, typically to refine its shape or size. This process is often performed after the initial stamping operations.

Embossing

The process of creating raised or recessed designs on the surface of a metal sheet. This is typically done for decorative purposes or for adding features such as logos or patterns.

Material

Brass

Aluminum

Steel

Stainless steel

Quality Control

The quality control of Precision Metal Fabrication Parts involves a comprehensive process to ensure the highest standards of accuracy and durability. From the selection of raw materials to the final inspection, every step is carefully monitored to maintain precision. Advanced measurement tools and techniques, such as CNC machines and laser measuring systems, are used to verify that each part meets the exact specifications. Thorough testing is conducted to assess the strength, corrosion resistance, and overall performance of the parts, ensuring they function reliably in their intended applications.

Processing capability

The processing capability of Precision Metal Fabrication Parts is centered on advanced technologies and precision techniques that allow for the creation of intricate, high-quality components. Utilizing CNC machining, laser cutting, stamping, and welding, the process ensures exceptional accuracy and flexibility for a wide range of materials such as stainless steel, aluminum, and carbon steel.

Additional processes

The additional processes for Precision Metal Fabrication Parts include a variety of finishing and enhancement techniques designed to improve the functionality, appearance, and durability of the components. These processes may involve surface treatments such as powder coating, anodizing, or plating to increase corrosion resistance and provide a smooth, uniform finish. Heat treatment is also commonly applied to improve the material's strength and hardness.