Product Description

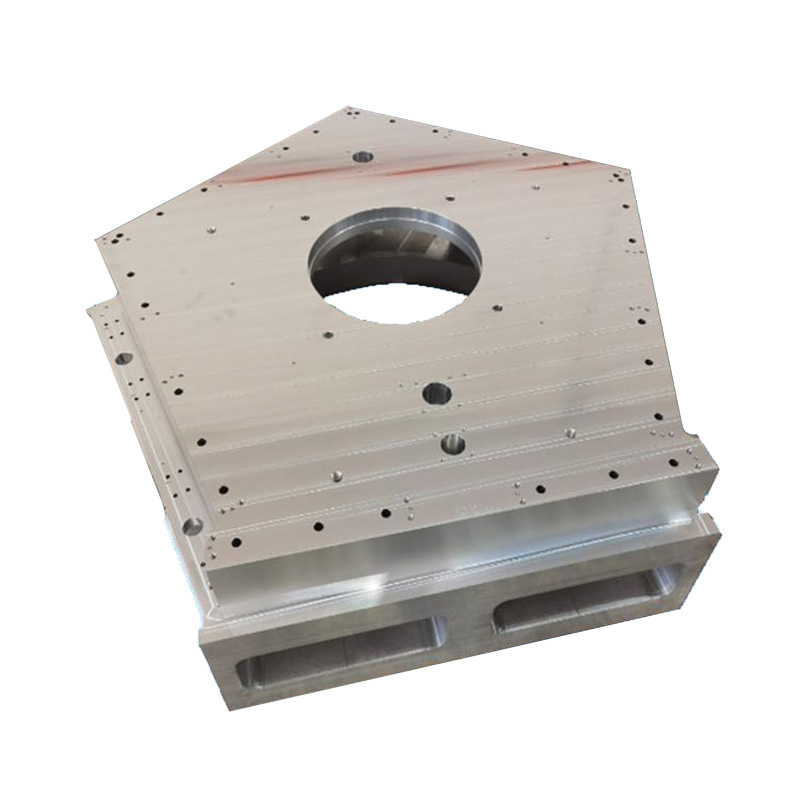

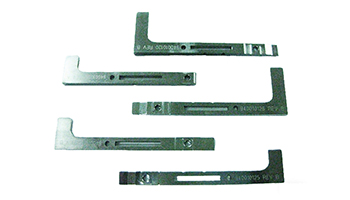

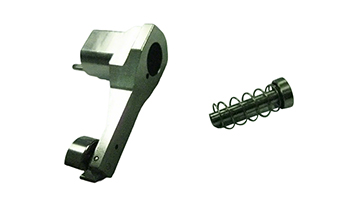

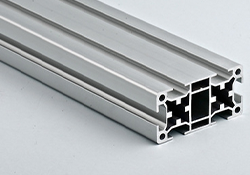

In the field of mechanical processing, precision and customization are the keys to success. We focus on professional non-standard customized metal CNC processing parts, and carve every detail with ingenuity. We select high-quality metal materials and use advanced CNC processing technology. No matter how complex the design is, we can turn it from a drawing into a high-precision object, providing exclusive customized solutions for your project.

Product parameters

| CNC Machining or Not | Cnc Machining |

| Material | Steel , Iron ,Stainless steel, Aluminum, Brass, Copper etc. |

| Certificate | ISO 9001:2015 |

| Quality Assurance | Professional testing personnel will do 100% checking |

Custom Process

1.Requirements communication

2.Scheme design

3.Quotation accounting

4.Contract signing

5.Raw material procurement

6.Processing and Manufacturing

7.Quality Inspection

8.Delivery acceptance

Process Type

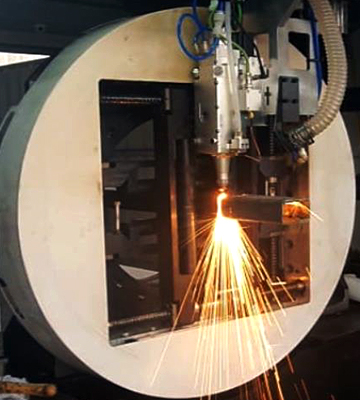

Laser cutting

With the help of the high temperature generated by the focused high-energy laser beam, the material is instantly melted or vaporized, and the sheet is cut with extremely high precision, with narrow and smooth cuts.

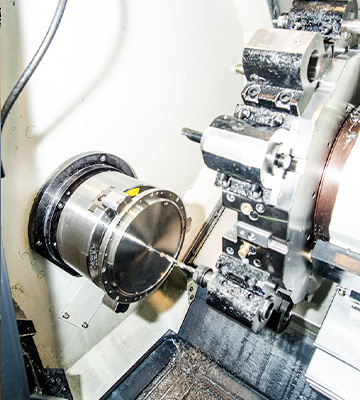

CNC Turning

CNC turning technology is a manufacturing process that uses computer digital control technology to accurately control lathes and perform precision cutting on rotating parts to achieve complex shapes and high-precision dimensional requirements.

Welding process

The welding process is a processing technology that uses heating, pressure, or a combination of both, with or without filler materials, to achieve atomic bonding of the welded parts and thereby connect the components into one body.

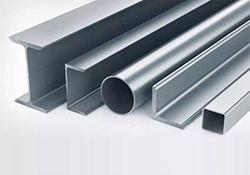

Material

Aloi Tembaga

Aloi Aluminium

Aluminium

Keluli tahan karat

Quality Control

In terms of quality control, we rely not only on advanced technical equipment, but also on a team of well-trained professionals. The technicians have a precise grasp of every processing parameter, and the inspectors carefully analyze every data. With their professional qualities and high sense of responsibility, they ensure that every product that flows out of our factory meets the highest quality standards.

Processing capability

CNC Milling Machine:

"CHEVALIER" CNC MACHINE CENTER (EM 2033 L) 1 UNITS

"CHEVALIER" CNC MACHINE CENTER (QP 2040 L) 1 UNIT

CNC MACHINE CENTER (CV 7 A) 2 UNIT

"SUNMILL" CNC MACHINE CENTRE (JHV 1500) 1 UNIT

CNC DOUBLE COLUMN MACHINIG CENTER (BMC 2012 A) 1 UNIT

"CHEVALIER" CNC MACHINE CENTER (QP1620-L) 1 UNIT

"IPM" VERTICAL MACHINING CENTER(MV-116D) 1 UNIT

"WELE LB 321" CNC DOUBLE COLUMN MACHINE CENTER 1 UNIT ( 5 FACE)

"WELE LB 421" CNC DOUBLE COLUMN MACHINE CENTER 1 UNIT ( 5 FACE)

Additional processes

Phosphating process is a process of forming phosphate chemical conversion film by chemical and electrochemical reaction, which is mainly used for metal surface treatment. This process can generate an insoluble phosphate film on the metal surface, significantly improving the metal's corrosion resistance, enhancing the adhesion between paint and other coatings and the metal substrate, and also improving the metal's wear resistance to a certain extent. The phosphating process is easy to operate and has low cost. It is widely used in many industries such as automobiles, machinery manufacturing, and home appliances.