Product Description

Our metal fabricators are dedicated to providing high-quality metal processing services. We specialize in customizing stainless steel and sheet metal products, from complex design to precision production, and we strictly control every step. Whether it is various types of welding parts or professional welding services, we can meet your diverse metal manufacturing needs with exquisite craftsmanship and reliable quality.

Product parameters

Size | Customer's Drawings |

Material | Steel , Iron ,Stainless steel, Aluminum, Brass, Copper etc. |

Surface treatment | Painting\Powder Coating\Plating\Polishing |

Our Service | Professional OEM ODM Custom Metal Fabrication |

Service | Custom Fabrication Services |

Custom Process

1.Requirements communication

2.Scheme design

3.Quotation accounting

4.Contract signing

5.Raw material procurement

6.Processing and Manufacturing

7.Quality Inspection

8.Delivery acceptance

Process Type

Welding process

The welding process is a processing technology that uses heating, pressure, or a combination of both, with or without filler materials, to achieve atomic bonding of the welded parts and thereby connect the components into one body.

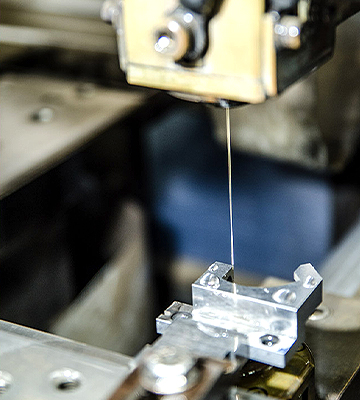

Laser cutting

With the help of the high temperature generated by the focused high-energy laser beam, the material is instantly melted or vaporized, and the sheet is cut with extremely high precision, with narrow and smooth cuts.

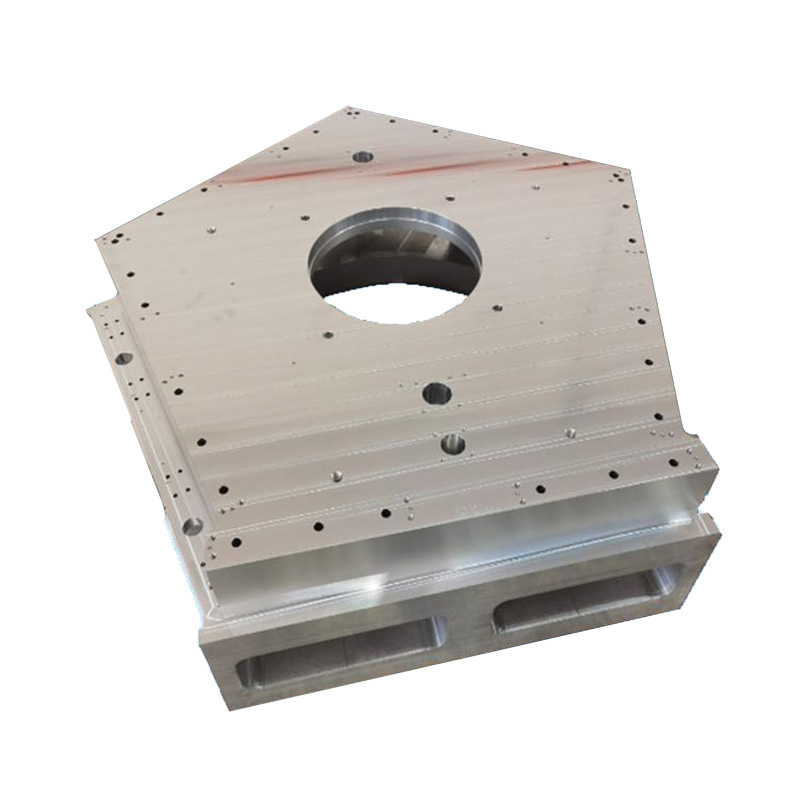

CNC Turning

CNC turning technology is a manufacturing process that uses computer digital control technology to accurately control lathes and perform precision cutting on rotating parts to achieve complex shapes and high-precision dimensional requirements.

Material

Stainless steel

Aluminum Alloy

Aluminum

Copper Alloy

Quality Control

Quality control is crucial in the production of precision customized sheet metal welded parts. Strict screening and testing are carried out from the source of raw materials to ensure that the materials meet the standards. On the production line, technicians use their superb skills and advanced equipment technology to monitor and accurately operate each process in real time. After welding is completed, high-precision instruments are used to fully test the finished products according to strict standards, without missing any minor defects. Products that have passed rigorous inspections are finally delivered to ensure excellent quality and reliable performance.

Processing capability

CNC Milling Machine:

"CHEVALIER" CNC MACHINE CENTER (EM 2033 L) 1 UNITS

"CHEVALIER" CNC MACHINE CENTER (QP 2040 L) 1 UNIT

CNC MACHINE CENTER (CV 7 A) 2 UNIT

"SUNMILL" CNC MACHINE CENTRE (JHV 1500) 1 UNIT

CNC DOUBLE COLUMN MACHINIG CENTER (BMC 2012 A) 1 UNIT

"CHEVALIER" CNC MACHINE CENTER (QP1620-L) 1 UNIT

"IPM" VERTICAL MACHINING CENTER(MV-116D) 1 UNIT

"WELE LB 321" CNC DOUBLE COLUMN MACHINE CENTER 1 UNIT ( 5 FACE)

"WELE LB 421" CNC DOUBLE COLUMN MACHINE CENTER 1 UNIT ( 5 FACE)

Additional processes

Internal powder coating process

We use an in-house powder spraying process to evenly adhere the powder to the surface of the workpiece using the principle of electrostatic adsorption. This process is environmentally friendly and efficient, with strong coating adhesion and good corrosion resistance. After high-temperature curing, the formed coating is flat and smooth, with long-lasting and bright colors, providing all-round protection and aesthetic protection for the product.