Huraian Produk

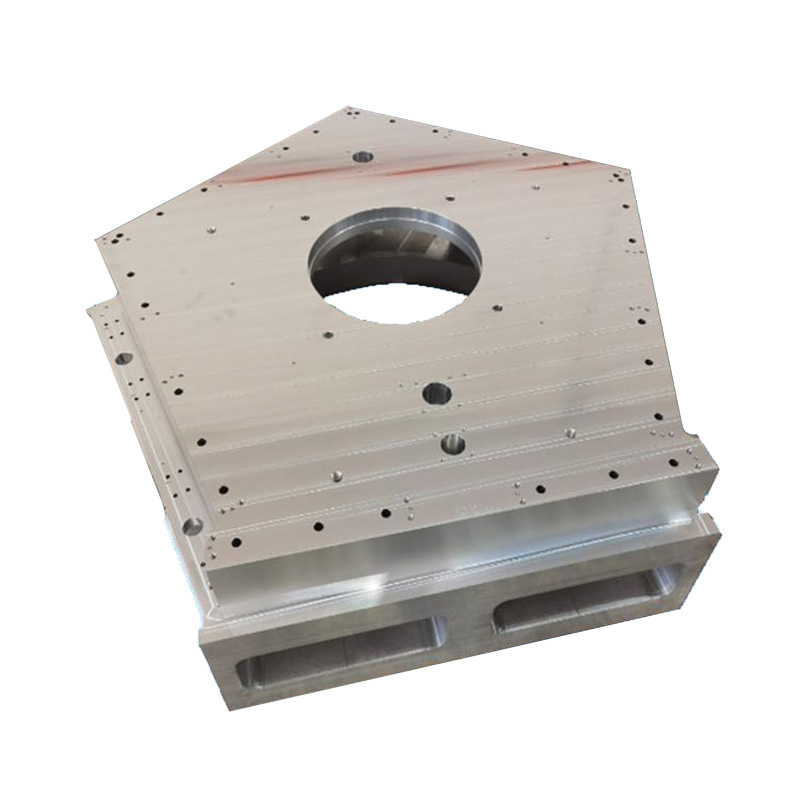

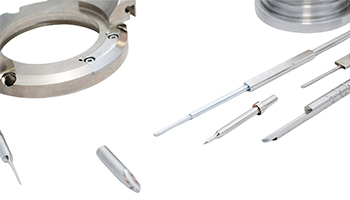

Kami pakar dalam perkhidmatan pemprosesan CNC tersuai dan pakar dalam pemprosesan CNC pelbagai bahagian logam. Dengan peralatan canggih dan ketukangan yang indah, kami boleh mengawal butiran pemprosesan dengan tepat dan merealisasikan dengan sempurna sebarang keperluan reka bentuk yang kompleks. Daripada bahan mentah kepada produk siap, pemeriksaan kualiti yang ketat dijalankan untuk memastikan setiap bahagian logam mempunyai kualiti yang sangat baik untuk memenuhi keperluan pengeluaran anda yang pelbagai.

Parameter produk

| Rawatan permukaan | Keperluan pelanggan |

| Memproses | Pemesinan CNC Pengilangan Memusing |

| Bahan | Keluli, besi, keluli tahan karat, aluminium, loyang, tembaga, dll. |

| warna | Warna tersuai |

| Saiz | Keperluan pelanggan |

| Servis | OEM tersuai |

Proses Suai

1.Komunikasi keperluan

2.Reka bentuk skema

3.Perakaunan sebutharga

4.Tandatangan kontrak

5.Perolehan bahan mentah

6.Pemprosesan dan Pembuatan

7.Pemeriksaan Kualiti

8.Penerimaan penghantaran

Material

Keluli tahan karat

Aluminium

Aloi Aluminium

Aloi Tembaga

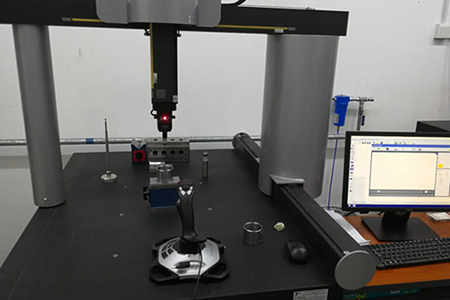

Kawalan Kualiti

Dalam bidang pemesinan ketepatan, kami yakin bahawa kualiti datang daripada butiran. Daripada pemilihan bahan mentah yang ketat, kepada setiap proses dalam pemprosesan, kepada beberapa pusingan ujian produk siap, proses kawalan kualiti kami adalah seperti instrumen ketepatan, yang dikaitkan bersama dan tidak membenarkan kesilapan sedikit pun. Setiap bahagian yang diproses yang meninggalkan kilang adalah bukti usaha berterusan kami untuk mencapai kualiti.

Kemampuan proses

Starvisi FG-3226

Paksi-X: 3200 mm

Paksi-Y : 2600 mm

Paksi Z : 1000 mm

Beban Meja : 13000 Kg

Kelajuan Spindle : 6000 rpm

Kebolehulangan : +/- 0.003 mm

Ketepatan Kedudukan : +/- 0.005/ 300 mm

: +/- 0.015 mm /Perjalanan Penuh

Proses tambahan

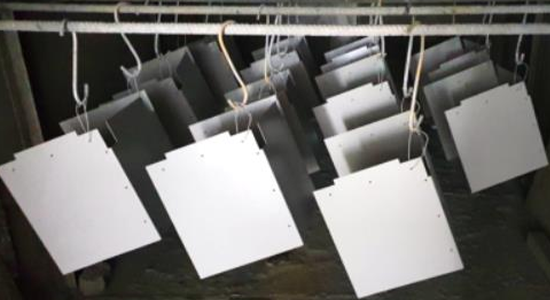

Proses salutan serbuk dalaman

Kami menggunakan proses penyemburan serbuk dalaman untuk melekatkan serbuk secara sekata pada permukaan bahan kerja menggunakan prinsip penjerapan elektrostatik. Proses ini mesra alam dan cekap, dengan lekatan salutan yang kuat dan rintangan kakisan yang baik. Selepas pengawetan suhu tinggi, salutan yang terbentuk adalah rata dan licin, dengan warna yang tahan lama dan cerah, memberikan perlindungan menyeluruh dan perlindungan estetik untuk produk.