Product Description

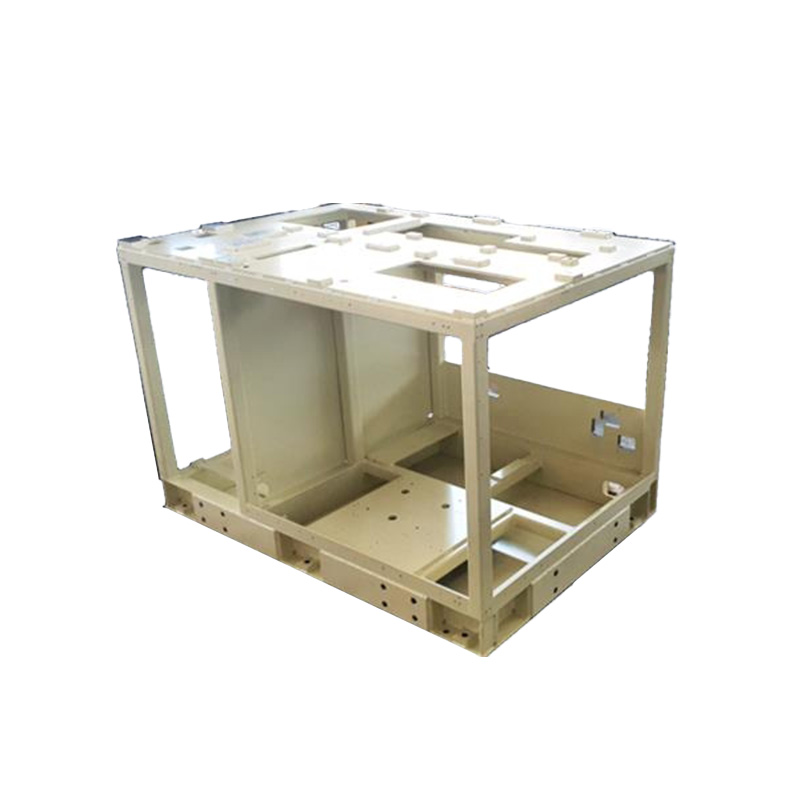

In the field of modern industrial manufacturing, precision and quality are the keys to success. We specialize in customizing sheet metal products and provide a full range of professional services to meet your project needs. Anodized aluminum bending and welding services are one of our core advantages. We use advanced CNC technology to accurately bend anodized aluminum materials, and control the angle error within a very small range to ensure that every bend meets the design standards. At the same time, we use precision welding technology to ensure that the welds are uniform and firm, and improve the overall appearance and durability of the product. High-precision sheet metal manufacturing services are even more refined, relying on high-precision processing equipment and a strict quality control system to meet your stringent requirements for product precision and help your project stand out.

Product parameters

| Product name | Sheet Metal Fabrication |

| Surface treatment | Galvanizing, Polishing, Anodizing, Powder coating, etc. |

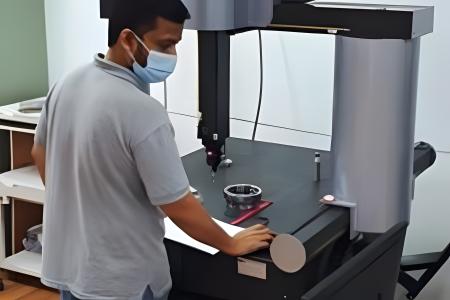

| QC Control | 100% Dimensional Inspection |

| Certificate | ISO 9001:2015 |

Custom Process

1.Requirements communication

2.Scheme design

3.Quotation accounting

4.Contract signing

5.Raw material procurement

6.Processing and Manufacturing

7.Quality Inspection

8.Delivery acceptance

Process Type

Welding process

The welding process is a processing technology that uses heating, pressure, or a combination of both, with or without filler materials, to achieve atomic bonding of the welded parts and thereby connect the components into one body.

Laser cutting

With the help of the high temperature generated by the focused high-energy laser beam, the material is instantly melted or vaporized, and the sheet is cut with extremely high precision, with narrow and smooth cuts.

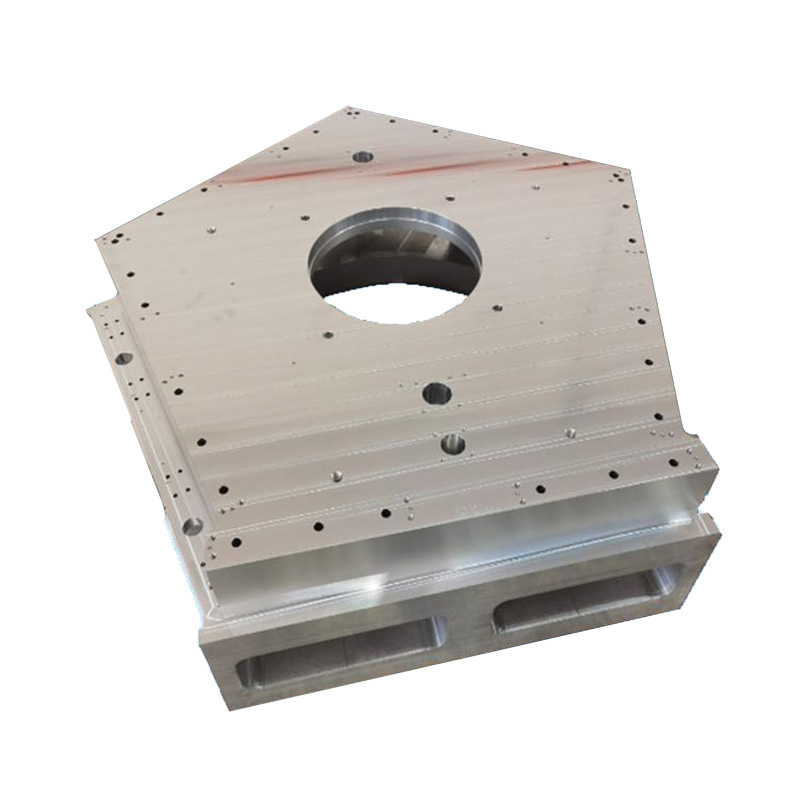

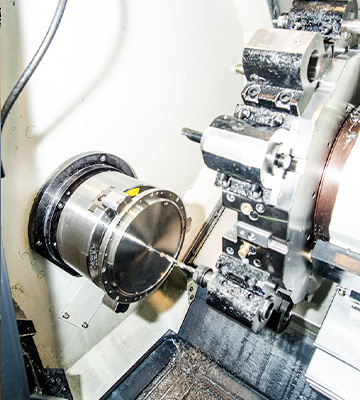

CNC Turning

CNC turning technology is a manufacturing process that uses computer digital control technology to accurately control lathes and perform precision cutting on rotating parts to achieve complex shapes and high-precision dimensional requirements.

Material

Stainless steel

Aluminum

Aluminum Alloy

Copper Alloy

Quality Control

In the field of precision machining and non-standard precision sheet metal welding, quality is our uncompromising commitment. From the strict selection of raw materials at the beginning, to the precise control of each process during processing, to multiple rounds of fine testing after welding, we have built a strict and complete quality control system. With a professional team and advanced technology, we strictly monitor the entire production process to ensure that each product meets high-precision standards and win the trust and praise of customers with excellent quality.

Processing capability

Momentum Vertical Lathes ( MVL-12)

Max. Tuning/Swing Diameter : Ø 1,600 mm

Table Diameter : Ø 1,250 mm

Max. Turning Height : 1,150 mm

Horizontal Travel (X Axis) : 1,000 mm

Vertical Travel (Z Axis) : 1,000 mm