Product Description

We specialize in providing high-quality casting services, excel in investment casting, and can create all kinds of non-standard precision castings. Through advanced CNC processing technology, we can precisely carve mechanical parts to ensure accurate dimensions and excellent performance. From casting to processing, we can meet your needs for high-precision mechanical parts in one stop and provide reliable guarantee for your project.

Product parameters

| Item | casting services |

| Material | metal |

| Surface treatment | Anodizing, Powder coating, Spray painting, Etc. |

| Size | As per drawing |

Custom Process

Demand communication

Product Design

Mold making

Material preparation

Process determination

Foundry production

Post-processing

Inspection and delivery

Process Type

High-pressure die casting

High-pressure die casting is a metal casting process that uses high pressure to quickly inject molten metal into the mold cavity and cool it to form. It has the advantages of high production efficiency, good casting precision, and good surface quality. It is widely used in the automotive, aviation and other industries.

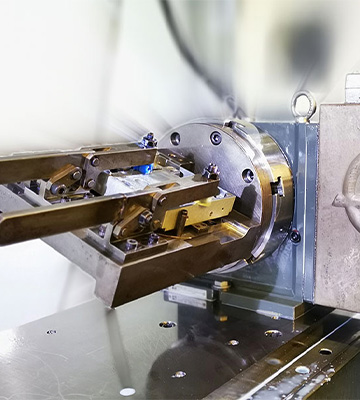

Turning process

Turning is a machining process in which the workpiece rotates and the turning tool moves and cuts on a lathe. It can perform a variety of turning operations such as external circles, internal holes, threads, and end faces. It has high machining accuracy and good surface quality, and can process a variety of materials.

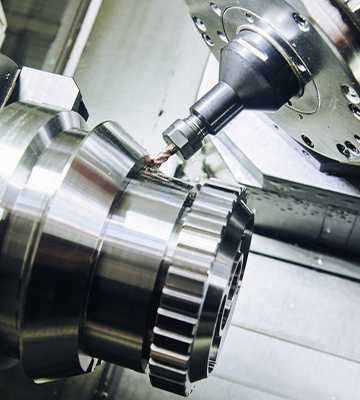

Milling process

Milling is a type of mechanical processing, in which the rotation of the milling cutter is the main motion, and the movement of the workpiece or the milling cutter is the feed motion. It can process various shapes such as planes, grooves, and forming surfaces. It has a variety of tools, high processing accuracy and efficiency, and is widely used in the field of mechanical manufacturing.

Material

Steel

Brass

Copper

Aluminum

Quality Control

1.Expertise and Experience: With years of experience in the industry, Sena Diecasting has honed its skills and expertise, making us a trusted name in diecasting.

2.Advanced Technology: We utilize the latest technology and equipment to ensure that our diecasting processes meet the highest standards of quality and efficiency.

3.Comprehensive Services: From diecasting to finishing and plating, Sena Diecasting offers a full range of services to meet all your needs.

Processing capability

High Pressure Diecasting

Machine Tonnage

1. High Pressure Diecasting Machine Tonnage from 135 tons up to 1,000 tons

2. Toshiba (135T/350T/800T)

3. Toyo (650T/900T/1,000T)

Others Facilities

Stress Relieved Oven、Melt and Hold Furnace、Crucible Furnace、Oil heater、Vacuum System、Fanuc Robot Spray、Fanuc Handling Robot

Additional processes

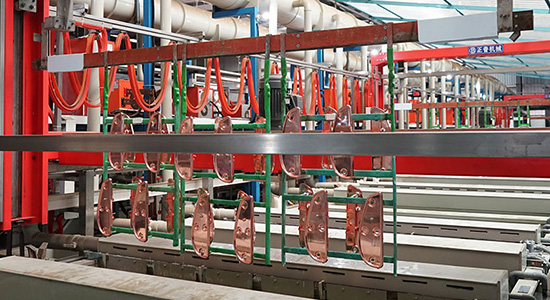

Chromium plating process

Generally, it includes pre-treatment such as degreasing and rust removal, and then the chromium ions in the chromium salt solution are reduced to metallic chromium on the surface of the workpiece through electroplating and other methods to form a chromium plating layer. There may be post-treatment such as passivation to improve corrosion resistance. The process can obtain a bright, wear-resistant and corrosion-resistant coating.