Product Description

Genesis Smith founded in year 2015, was first located in a shop lot in Sungai Jawi, Penang. We continued to grow and in year 2018, we moved to current 12,000 square feet facility with a full-fledged machine shop in-house which allowing us to provide a complete sheet metal and machining fabrication solutions to our customers.

We provide the delicateness design and highest quality service in precision machining, first article fabrication quantities to mass production quantities, out-source surface finishing and other fabrication services which enable to offer complete solution.

Product parameters

| Processing | CNC turning, CNC milling, CNC machining, Grinding, EDM wire cutting |

| Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Titanium | |

| Plastic:POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | |

| Surface Treatment | Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

| File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,etc. |

| Quality Assurance | ISO9001, IATF 16949, SGS, RoHs, |

Custom Process

1. Send Drawing

2. Inquiry

3. Negotiation

4. Production

5. Quality Inspection

6. Packaging

7. Transportation

8. After-Sales Support

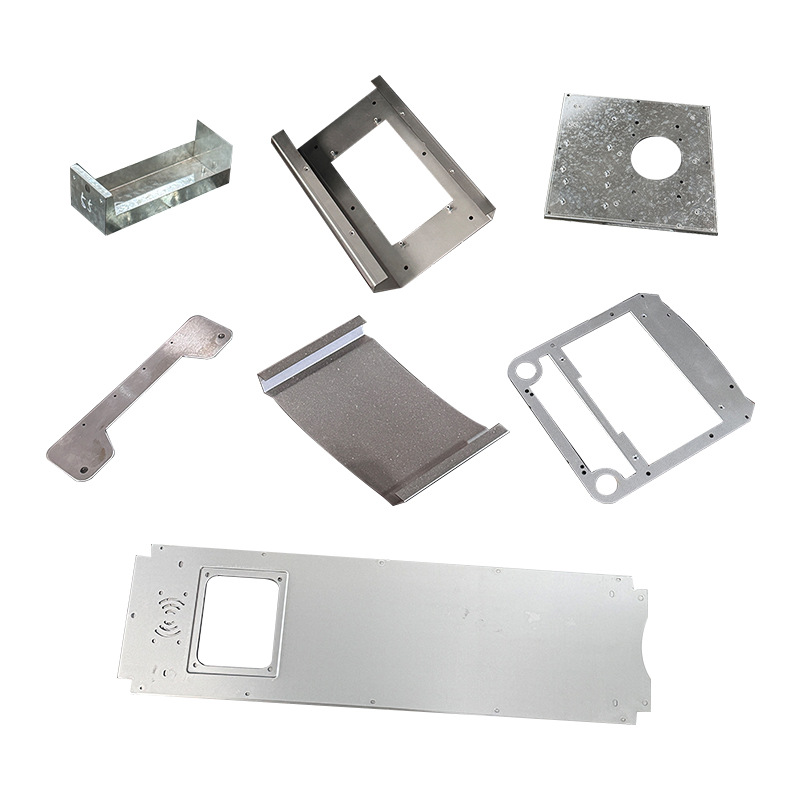

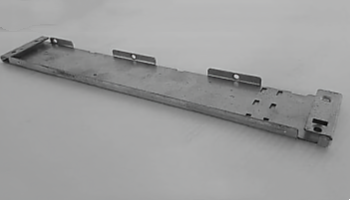

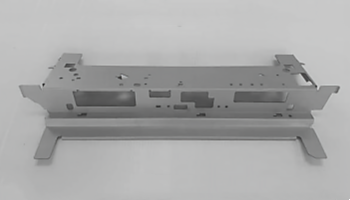

Process Type

Blanking

Piercing

Bending

Material

Stainless steel

Carbon Steel

Aluminum Alloy

Plastic

Processing capability

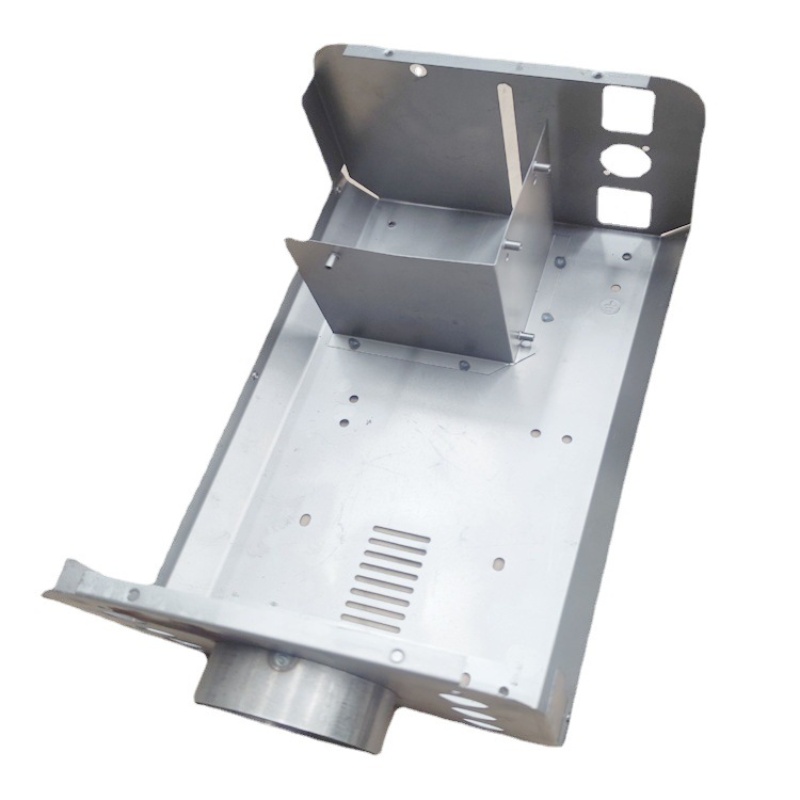

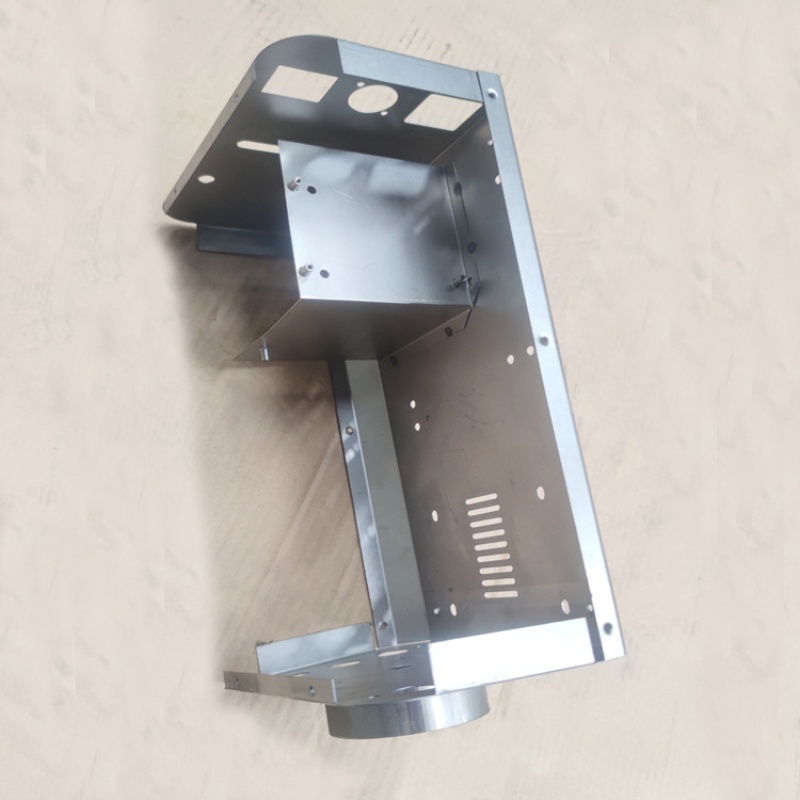

Primary Sheet Metal Processes

- Laser cut (Sheet & Tube)

- Laser press

- Bending

Machining Processes

- CNC Milling & Turning

- Conventional Milling & Turning

- Precision Grinding

Secondary Processes

- Manual Deburring

- Orbital & Hairline Polish

- Threading (Tapping)

- Clinching

- Sand Blast

- Assembly

- Riveting

- Laser Engraving

Additional processes

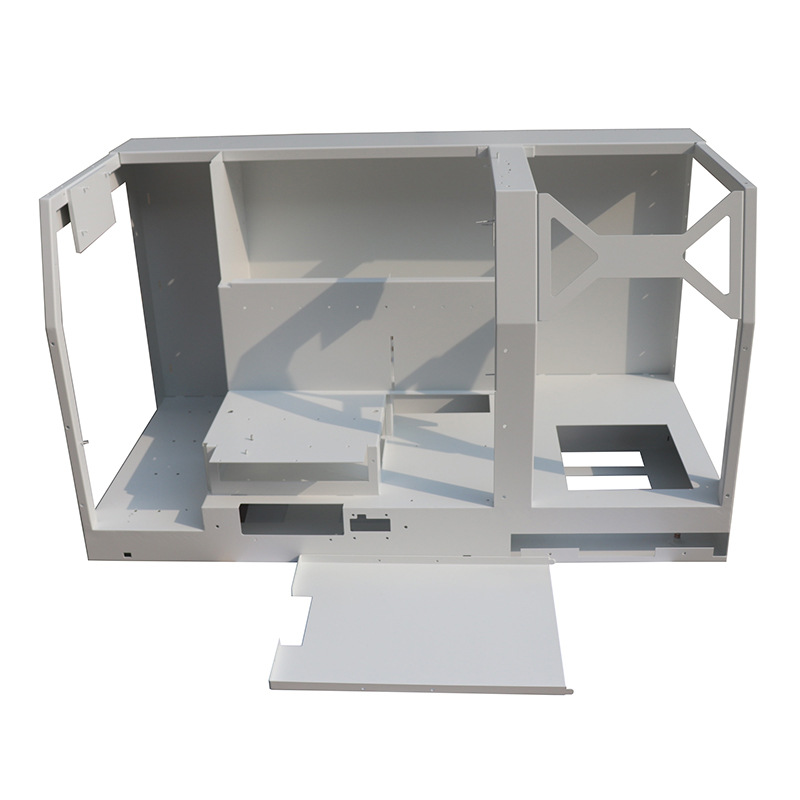

Powder Coating

Powder coating is a highly durable finishing process that involves applying a dry powder to the surface of a part, which is then cured under heat to form a hard, resilient layer. This process creates a smooth, even coating that is more resistant to scratches, chips, and fading compared to traditional paint. Powder coating is ideal for components exposed to harsh environments, as it provides superior protection against corrosion, weathering, and wear. Additionally, powder coating is available in a wide range of colors and textures, making it a versatile option for both functional and aesthetic applications. At Genesis Smith, we ensure a precise and uniform application, delivering a high-quality finish that enhances the longevity and appearance of your parts.

Wet Painting

Wet painting, also known as liquid painting, is a finishing process where liquid paint is applied to a part using spray, dip, or brush methods. This technique allows for a wide variety of finishes, including glossy, matte, and textured surfaces, with an extensive range of color choices. Wet painting provides an excellent finish for parts that require smooth, even coverage and is often used when a high-quality, professional appearance is essential. Unlike powder coating, wet painting can be applied to parts of complex shapes and sizes, offering flexibility in design. Genesis Smith’s wet painting service is carried out with precision, ensuring consistency, smooth application, and a high-standard finish for every component we treat.