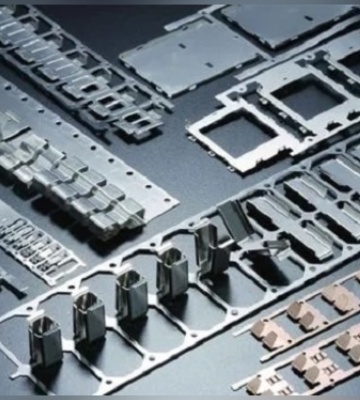

Product Description

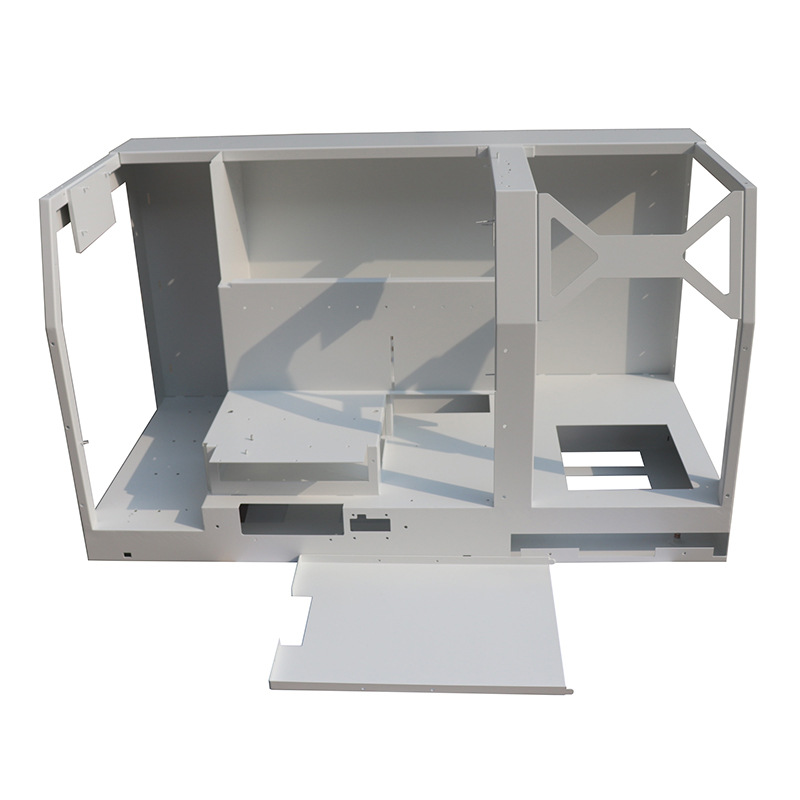

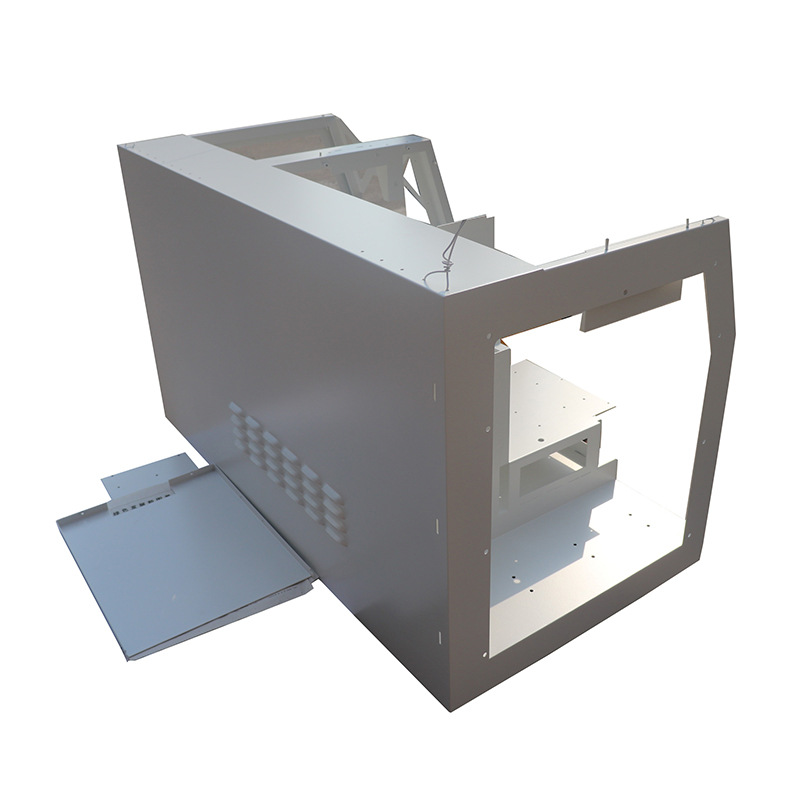

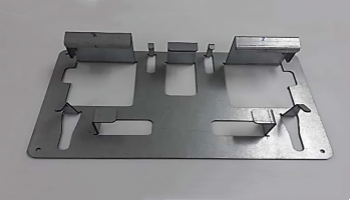

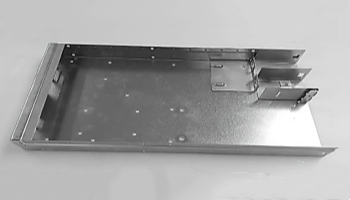

We Provide Sheet Metal and Machining Fabrication Solutions. We have a talents, experiences and experts team work geared to provide complete engineering solution, fabrication of precision machining parts, sheet metal parts, welded structures, sub-assembly module and we share our experience in design and development service into a comprehensive range of products.

Genesis Smith have been awarded with ISO 9001:2005 Certification, an internationally recognized standard that ensures our products and services meet the clients needs through an effective Quality Management System.

Product parameters

| Processing | CNC turning, CNC milling, CNC machining, Grinding, EDM wire cutting |

| Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. |

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | |

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | |

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | |

| Titanium | |

| Plastic:POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | |

| Surface Treatment | Anodizing,Brushing,Galvanized,laser engraving, Silk printing,polishing,Powder coating,etc |

| File Formats | Solid Works,Pro/Engineer, AutoCAD(DXF,DWG), PDF,etc. |

| Quality Assurance | ISO9001, IATF 16949, SGS, RoHs, |

Custom Process

1. Send Drawing

2. Inquiry

3. Negotiation

4. Production

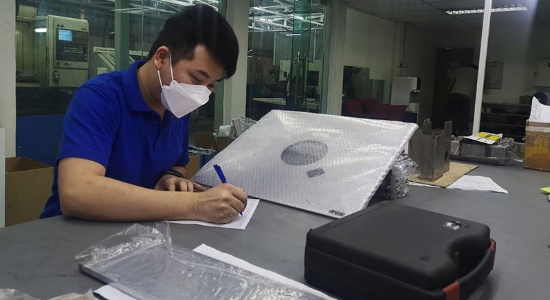

5. Quality Inspection

6. Packaging

7. Transportation

8. After-Sales Support

Process Type

Embossing

Coining

Deep Drawing

Material

Stainless steel

Carbon Steel

Aluminum Alloy

Plastic

Processing capability

Primary Sheet Metal Processes

- Laser cut (Sheet & Tube)

- Laser press

- Bending

Machining Processes

- CNC Milling & Turning

- Conventional Milling & Turning

- Precision Grinding

Secondary Processes

- Manual Deburring

- Orbital & Hairline Polish

- Threading (Tapping)

- Clinching

- Sand Blast

- Assembly

- Riveting

- Laser Engraving

Additional processes

Powder Coating

Powder coating is a highly durable finishing process that involves applying a dry powder to the surface of a part, which is then cured under heat to form a hard, resilient layer. This process creates a smooth, even coating that is more resistant to scratches, chips, and fading compared to traditional paint. Powder coating is ideal for components exposed to harsh environments, as it provides superior protection against corrosion, weathering, and wear. Additionally, powder coating is available in a wide range of colors and textures, making it a versatile option for both functional and aesthetic applications. At Genesis Smith, we ensure a precise and uniform application, delivering a high-quality finish that enhances the longevity and appearance of your parts.

Powder Coating Oven

L-6000mm x W-3000mm x H-3000mm

Our state-of-the-art Powder Coating Oven, with dimensions of L-6000mm x W-3000mm x H-3000mm, is designed to efficiently cure large and complex components with precision and consistency. The spacious interior allows us to accommodate a wide range of part sizes, ensuring that even oversized or intricate pieces receive uniform heat distribution for optimal curing. This advanced oven is equipped with temperature control systems that ensure precise and even heat application, allowing the powder coating to bond effectively and form a durable, long-lasting finish. Whether for small or large production runs, our Powder Coating Oven delivers high-quality results, enhancing the performance and appearance of your parts while meeting the highest standards of durability and finish.