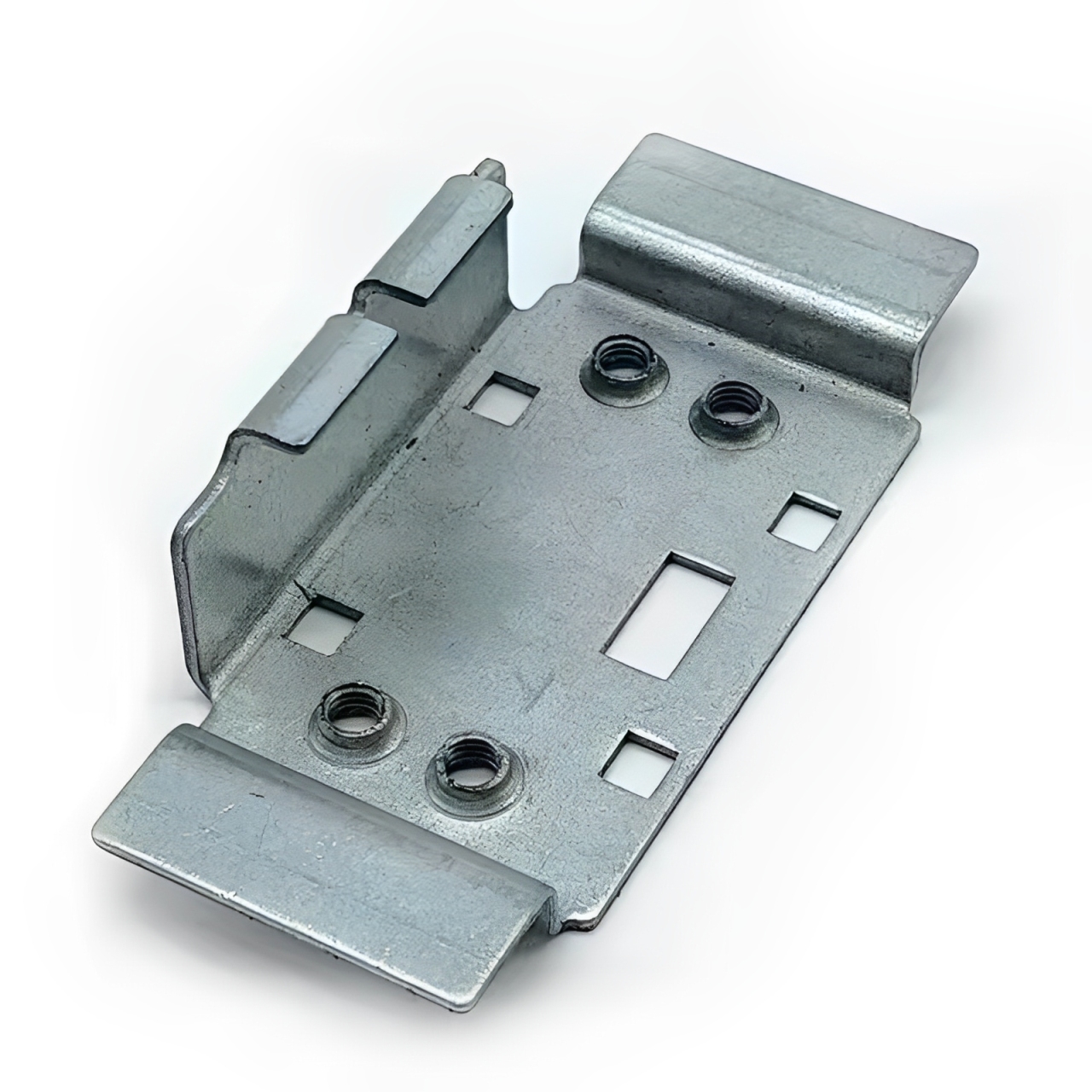

Product Description

The custom high-precision seal housing is perfectly designed for durability, efficiency, and long service life. Using advanced CNC machining, it ensures precise dimensions and high-quality materials for a variety of industrial and mechanical applications. Each piece is carefully crafted to meet stringent standards, providing the highest level of reliability and performance in critical processes.

Product parameters

| Product Size (Diameter * Height) | 360*360*42 |

| Feature | Long Service Life Precision Durable Eco-friendly Sustainable |

| Service | OEM Customized |

| Advantage | Professional Technology High Quality |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmatiol

Process Type

Laser Cutting and TIG Welding

Punching and MIG Welding

CNC Bending and Spot Welding

Material

Aluminu Alloy

Stainless Steel

Brass

Copper

Quality Control

The quality control process for Customized Seal Housing CNC Parts ensures precise dimensions, durability, and optimal performance. Each component undergoes thorough inspections, including material verification, dimensional accuracy checks with advanced measuring tools, and surface finish assessments. Rigorous testing is conducted to guarantee the parts meet industry standards and specific customer requirements.

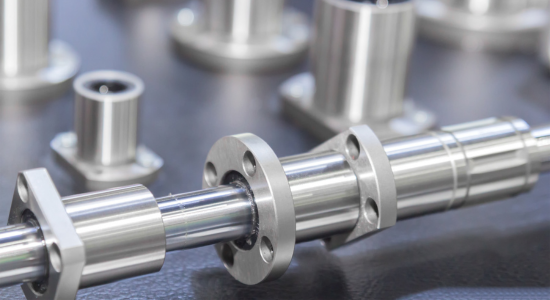

Processing capability

The processing capability of Customized Seal Housing CNC Parts includes precision machining for complex shapes, tight tolerances, and high-quality surface finishes. Utilizing advanced CNC technology, we can produce parts from a variety of materials with high efficiency and consistency. Our capabilities extend to various machining processes, including milling, turning, drilling, and tapping, ensuring each component meets exact specifications.

Additional processes

The additional processes for Customized Seal Housing CNC Parts include heat treatment for enhanced strength and durability, surface coating for improved corrosion resistance, and assembly services for integrated solutions. We also offer polishing, deburring, and cleaning to ensure smooth finishes and precise functionality. Depending on customer requirements, we can incorporate further customizations such as threading, engraving, and other specialized treatments to ensure the parts meet the highest industry standards and perform flawlessly in their intended applications.