Product Description

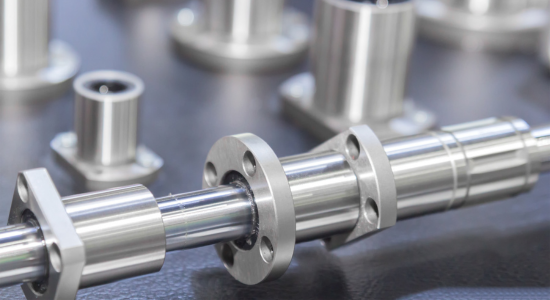

Custom CNC gear parts with high precision, durability, and reliability are designed to meet the specific requirements of various industrial and mechanical applications. Manufactured using advanced CNC machining technology, these parts are crafted with meticulous attention to detail, ensuring exceptional performance in even the most demanding environments. With the ability to handle complex geometries and tight tolerances, these custom gears provide superior strength, smooth operation, and extended lifespan.

Product parameters

| Product Size (Diameter * Height) | 360*360*42 |

| Feature | Long Service Life Precision Durable Eco-friendly Sustainable |

| Service | OEM Customized |

| Advantage | Professional Technology High Quality |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmatiol

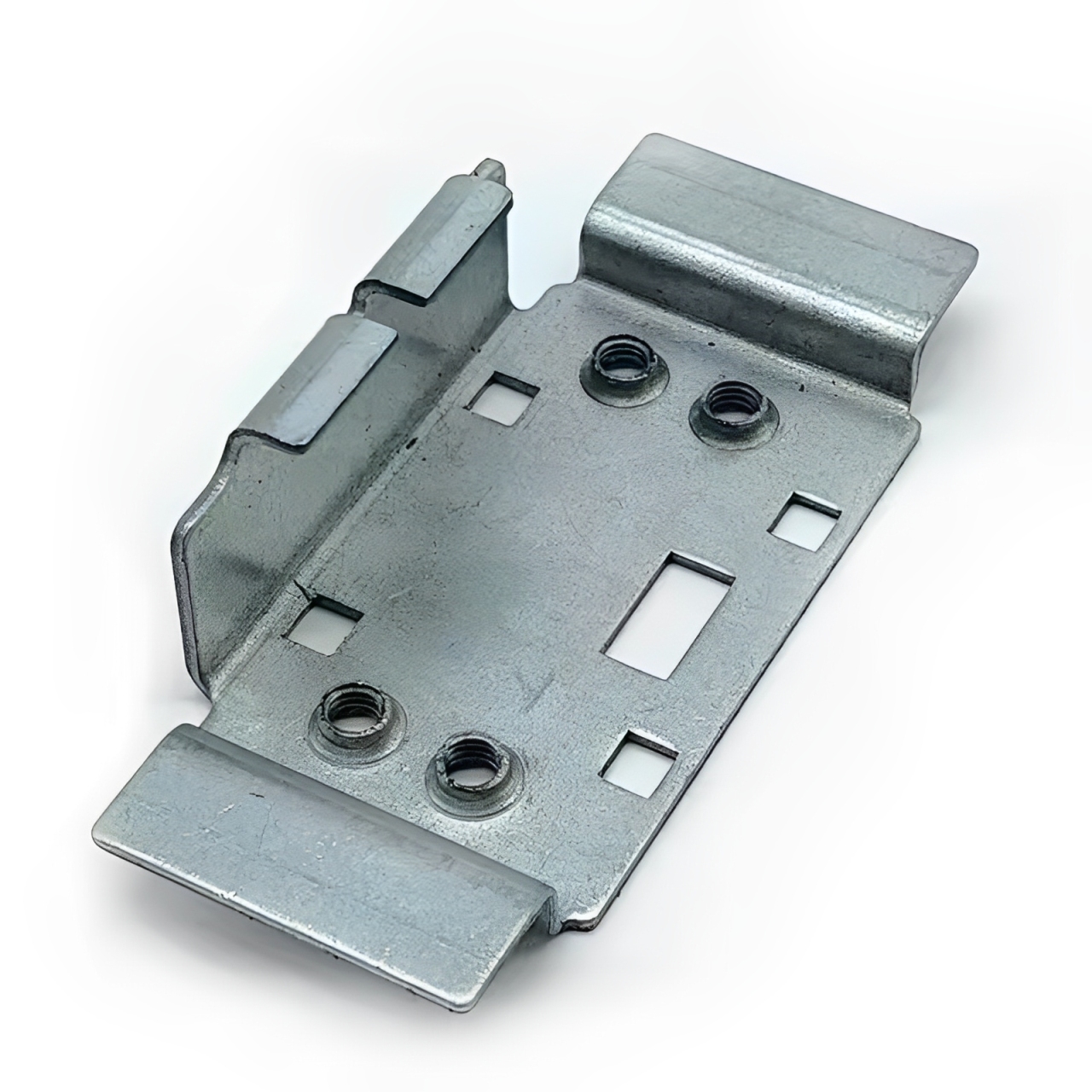

Process Type

Laser Cutting and TIG Welding

Punching and MIG Welding

CNC Bending and Spot Welding

Material

Aluminu Alloy

Stainless Steel

Brass

Copper

Quality Control

The quality control of Custom CNC Gear Parts involves a comprehensive approach to ensure each part meets the highest standards of precision and performance. From the initial material selection to the final inspection, every step is carefully monitored. Advanced measuring instruments, such as coordinate measuring machines (CMM), are used to verify dimensional accuracy and ensure tight tolerances. Each gear undergoes surface finish inspections to confirm smooth operation and minimal wear.

Processing capability

The processing capability of Custom CNC Gear Parts combines advanced CNC machining techniques with high precision to create complex, custom designs with tight tolerances. Our capabilities include machining gears with various tooth profiles, such as spur, helical, and bevel gears, using state-of-the-art equipment to ensure accuracy. We are capable of working with a wide range of materials, including metals like steel, aluminum, and brass, and can accommodate both small and large production runs.

Additional processes

The additional processes for Custom CNC Gear Parts include heat treatment to enhance strength and wear resistance, surface coatings for improved corrosion protection, and fine polishing to achieve a smooth finish for optimal performance. We also provide assembly services, ensuring that gears are integrated with other components seamlessly. Depending on the requirements, processes such as balancing, threading, and gear tooth finishing are applied to ensure precision and flawless functionality.