Product Description

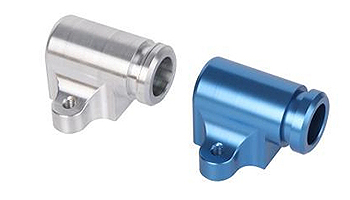

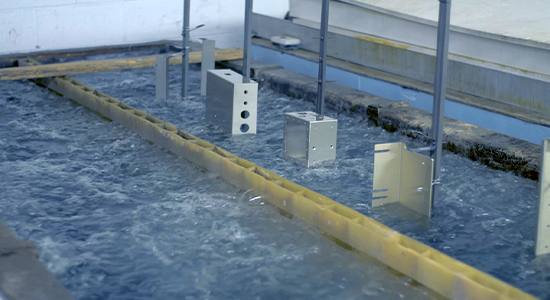

We specialize in custom CNC machining services, focusing on anodized aluminum technology to achieve high-precision milling and spare turning of metal parts. As an experienced manufacturer, we strictly control the production process and can customize various precision parts according to your needs to meet your diverse needs with excellent quality.

Product parameters

| Application | Industrial Equipment |

| Color | Customized Color |

| Service | Customized OEM |

| In-house facilities | 3 Axis CNC turning— 10 Set Swiss Lathe— 5 Set |

Custom Process

1. Demand communication

2. Solution design

3. Quotation

4. Contract signing

5. Prepayment

6. Production delivery

7. Inspection and acceptance

8. Final payment settlement

Material

Steel

Aluminum

Copper

Stainless steel

Quality Control

Implementation of Quality Standards in AMG Vietnam:

To meet these standards, AMG Vietnam would likely follow a structured quality management system, incorporating the following:

Incoming Material Inspection: To ensure raw materials meet required specifications.

In-Process Inspections: Monitoring critical stages of production to detect and correct defects early.

Processing capability

CNC Machine Workshop is a specialized facility where Computer Numerical Control (CNC) machines are used to manufacture high-precision parts and components. In this type of workshop. CNC machines are the main tools for performing intricate . Precise machining operations, such as milling, turning, drilling, and grinding, with minimal human intervention

Additional processes

Many manifolds need to be surface treated after manufacturing. For metal manifolds, the most common treatment is anodizing. For example, anodizing of aluminum alloy intake manifolds can improve their surface hardness, wear resistance and corrosion resistance.