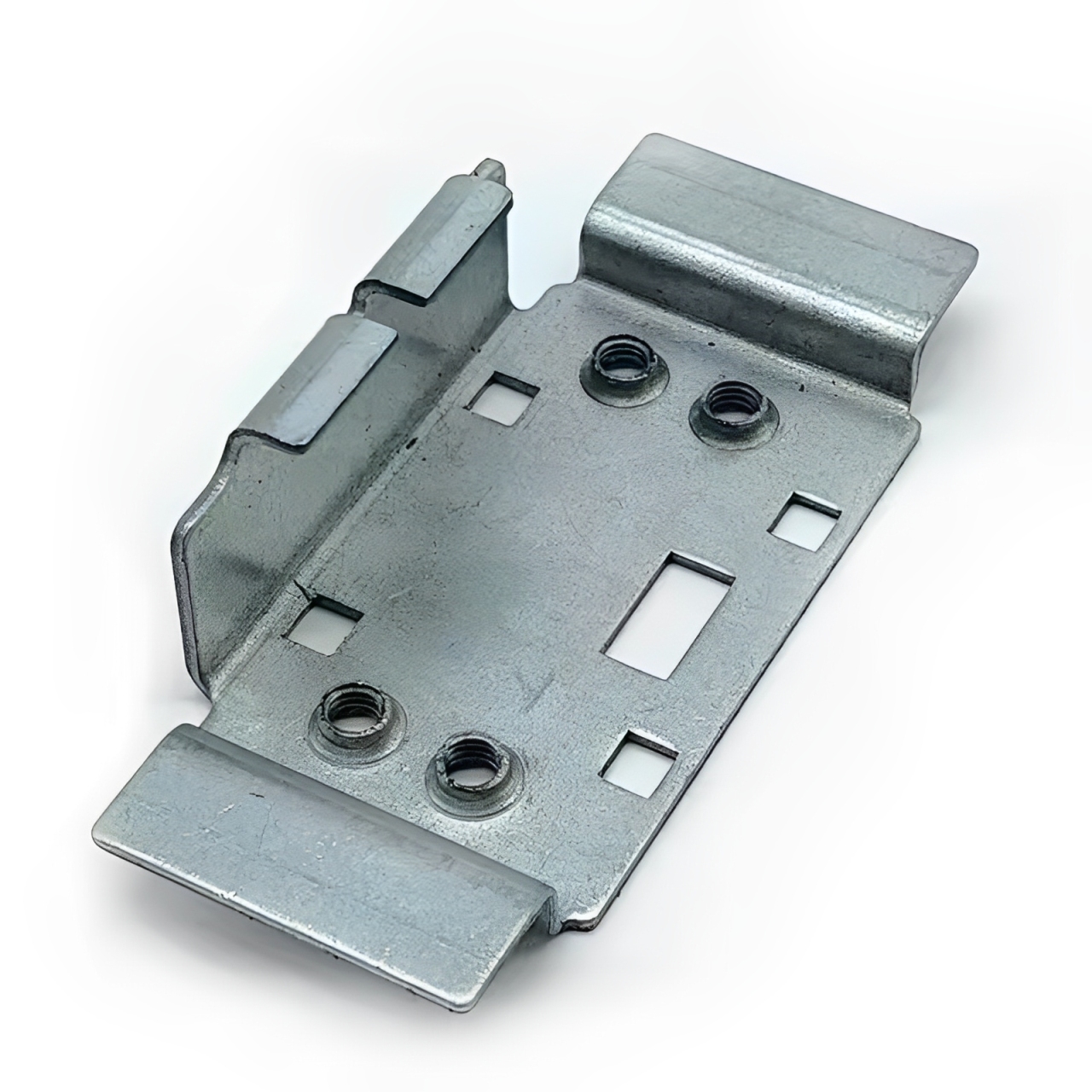

Product Description

Precision CNC Services: We are experts in machining a wide variety of metals, including aluminum, stainless steel, and other alloys, providing high-quality turning, milling, and rapid prototyping solutions. Our state-of-the-art CNC equipment allows for precision cutting, shaping, and machining of complex geometries with tight tolerances. Whether you're looking for custom parts, prototypes, or small to large-scale production runs, we deliver efficient, reliable, and cost-effective solutions.

Product parameters

| Processing | CNC turning, CNC milling, | |||

| Materials | Aluminum: 2000 series, 6000 series, 7075, 5052, etc. | |||

| Stainless steel: SUS303, SUS304, SS316, SS316L, 17-4PH, etc. | ||||

| Steel: 1214L/1215/1045/4140/SCM440/40CrMo, etc. | ||||

| Brass: 260, C360, H59, H60, H62, H63, H65, H68, H70, Bronze, Copper | ||||

| Titanium: Grade F1-F5 | ||||

| Plastic: Acetal/POM/PA/Nylon/PC/PMMA/PVC/PU/Acrylic/ABS/PTFE/PEEK etc. | ||||

| Surface Treatment | Anodized, Bead Blasted, Silk Screen, PVD Plating, Zinc/Nickel/Chrome/Titanium Plating, Brushing, Painting, Powder Coated, | |||

| Passivation, Electrophoresis, Electro Polishing, Knurl, Laser/Etch/Engrave etc. | ||||

| Tolerance | +/-0.002~+/-0.005mm | |||

| Surface Roughness | Min Ra 0.1~3.2 | |||

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmatiol

Process Type

Laser Cutting and TIG Welding

Punching and MIG Welding

CNC Bending and Spot Welding

Material

Aluminu Alloy

Stainless Steel

Brass

Copper

Quality Control

At Precision CNC Service, quality control is at the heart of everything we do. From the initial selection of materials to the final inspection, we employ rigorous standards to ensure every part meets the highest level of precision and functionality. Our team uses advanced measurement tools and testing techniques throughout the machining process to verify that each component adheres to exact specifications.

Processing capability

Precision CNC Service offers advanced machining capabilities, specializing in high-precision turning, milling, and rapid prototyping for a wide range of materials, including aluminum, stainless steel, and other metals. Using state-of-the-art CNC equipment, we are able to produce components with tight tolerances and complex geometries, meeting the most demanding specifications. Our versatile capabilities allow us to handle both small and large production runs, ensuring efficiency and accuracy throughout.

Additional processes

At Precision CNC Service, we offer a variety of additional processes to complement our core machining services. These include advanced surface treatments, such as anodizing, plating, and polishing, to enhance the durability, corrosion resistance, and overall finish of the parts. Our team also provides custom coatings for improved wear resistance and longevity, along with post-machining inspection to ensure each component meets exact specifications. With these additional processes, we are able to deliver a fully finished product that meets both functional and aesthetic requirements, ensuring superior quality and performance in every part.