Product Description

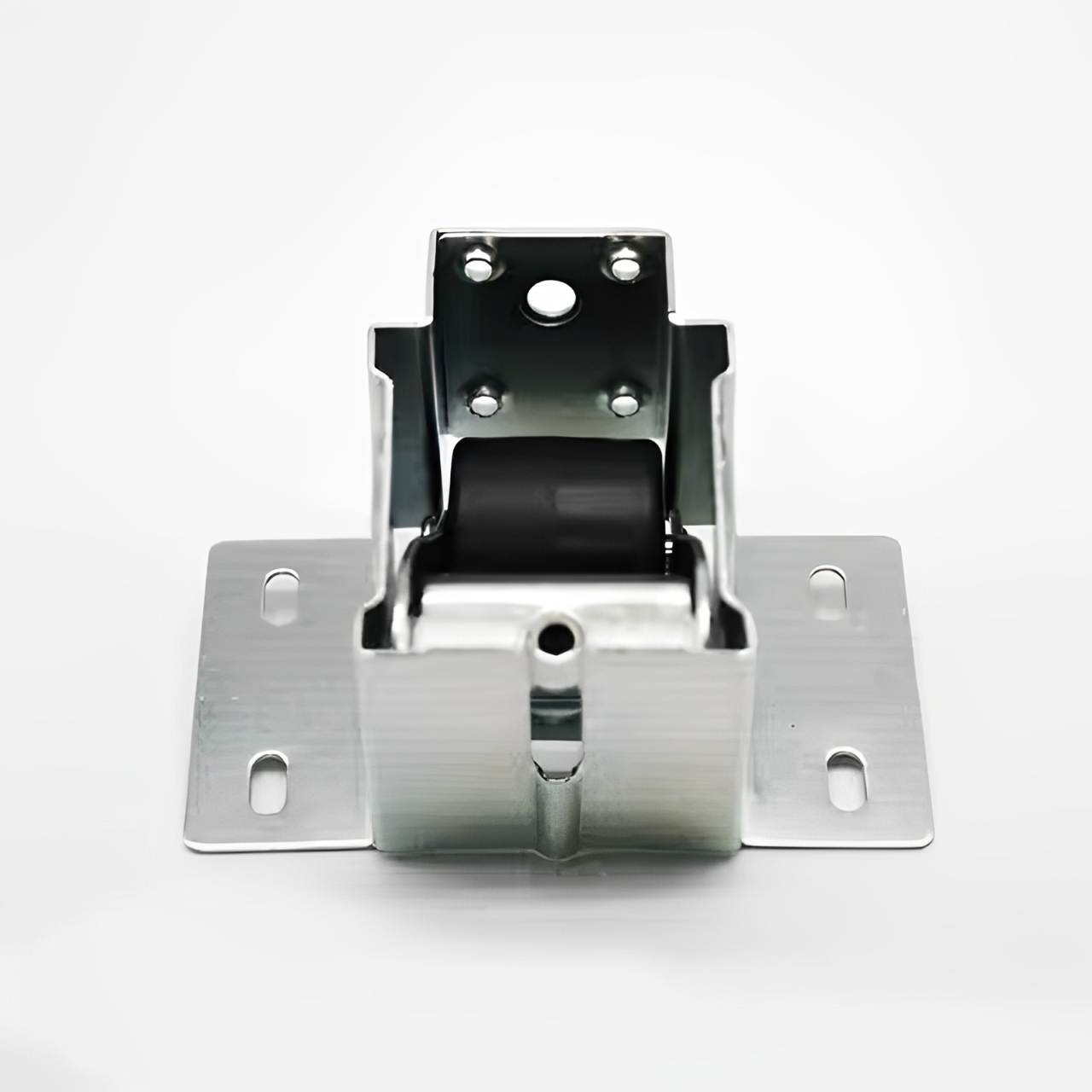

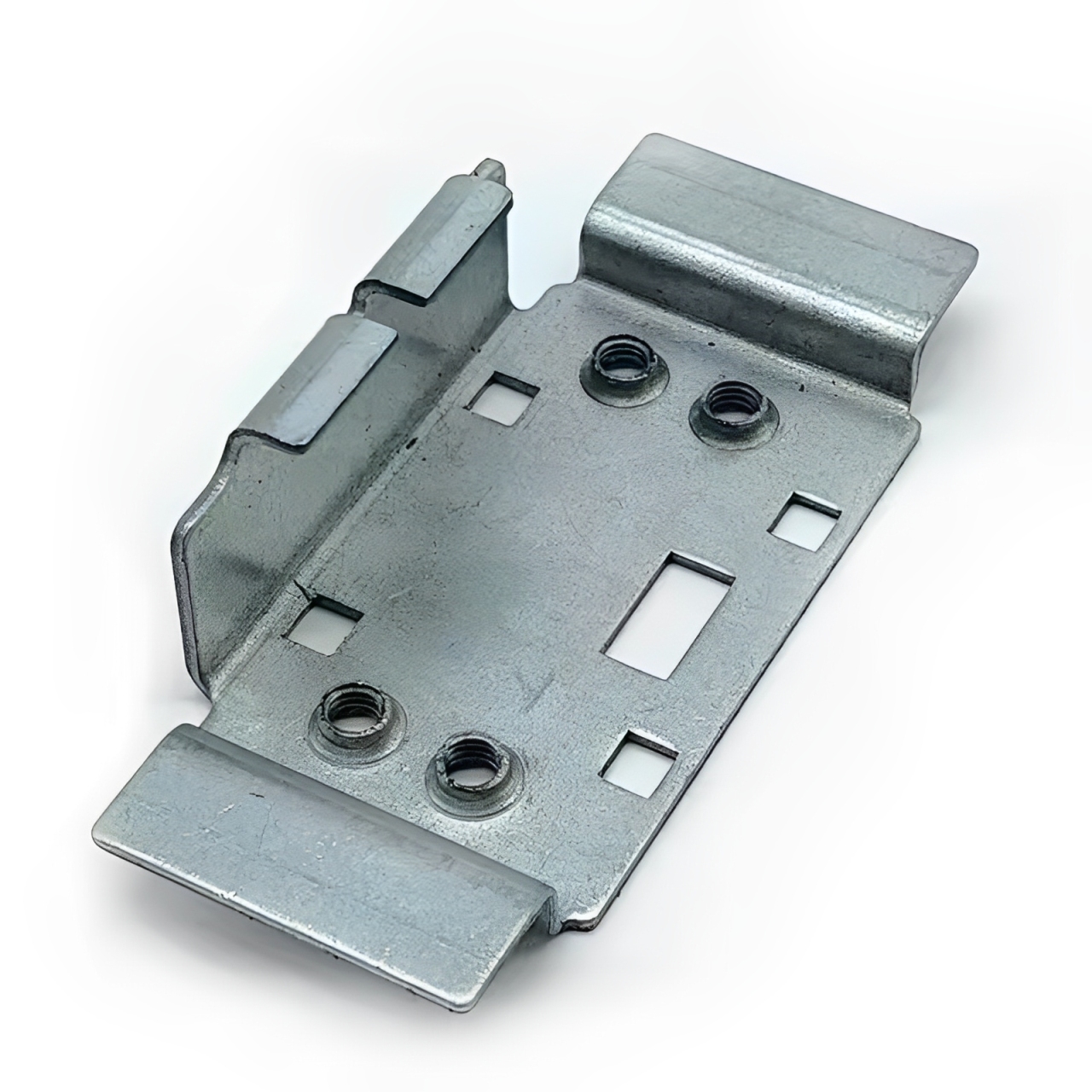

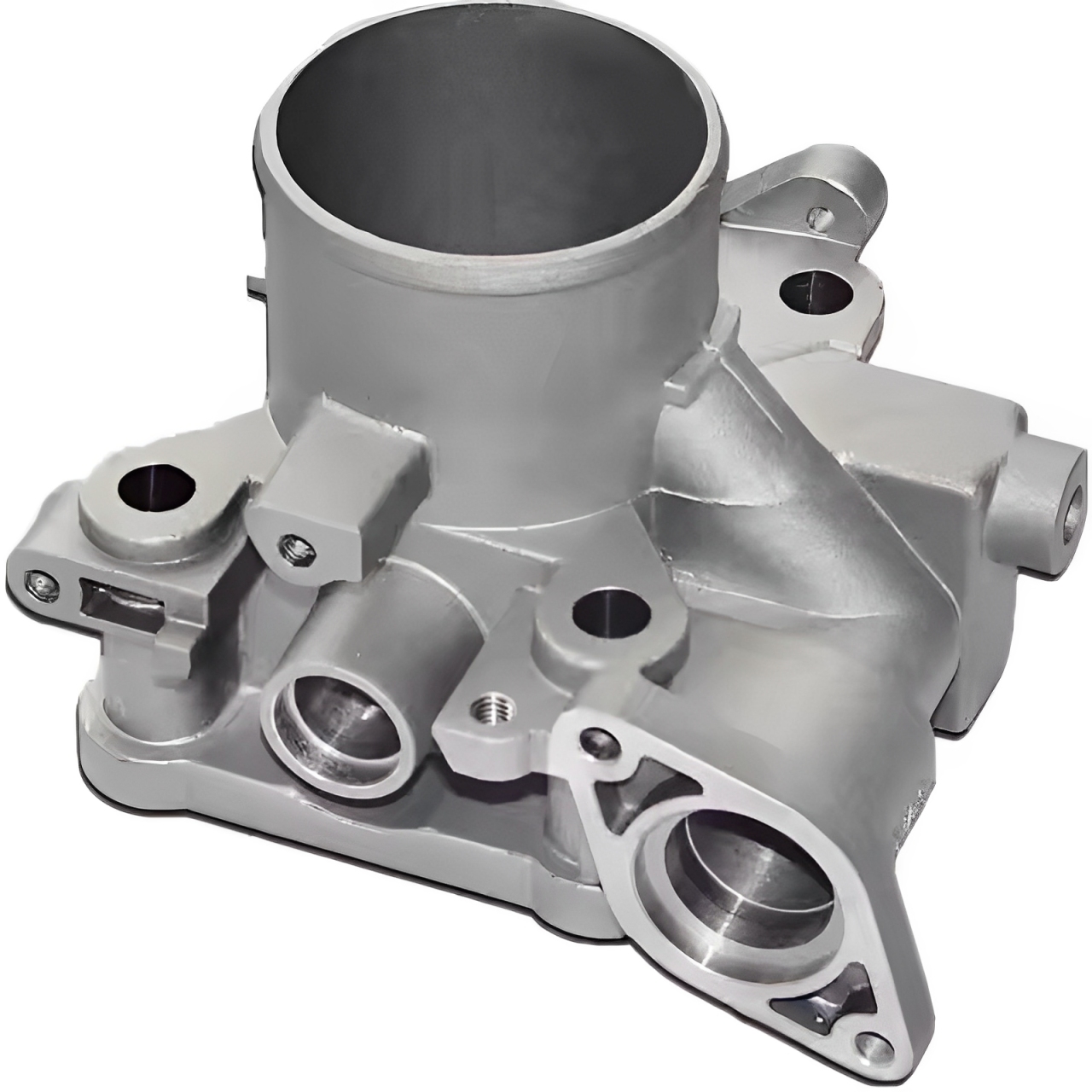

Precision Metal Processing: Offering expert metal bending, welding, and stamping services to meet the highest standards of precision. Our processes ensure accurate, high-quality, and durable results, designed to meet the demanding needs of various industrial applications. From design to production, we focus on delivering reliable solutions that optimize performance and longevity, ensuring that each part meets exact specifications and withstands the toughest conditions.

Product parameters

| Product name | Precision Metal Processing |

| Model number | MS01-01 |

| place of origin | china |

| color | silver |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmatiol

Process Type

TIG Welding (Tungsten Inert Gas Welding)

This process uses a tungsten electrode and an electric arc to melt the edges of parts, with argon gas protecting the weld area from oxidation. It is ideal for welding thin metals and requires high precision

MIG Welding (Metal Inert Gas Welding)

This process involves feeding a wire electrode into the weld area, with a shielding gas (such as carbon dioxide) protecting the weld from contamination. It is suitable for high-speed and efficient welding operations.

Spot Welding

A process where heat and pressure are applied to a specific spot to join metal parts, often used for welding thin sheet metals, commonly found in the automotive industry.

Material

Aluminu Alloy

Stainless Steel

Brass

Copper

Quality Control

Quality Control of Precision Metal Processing ensures that every part undergoes rigorous inspection throughout the entire production process. From material selection to the final product, we apply advanced measurement tools and techniques to guarantee the highest level of accuracy and consistency. Each part is tested for dimensional precision, structural integrity, and performance reliability, ensuring it meets the specific requirements of the customer.

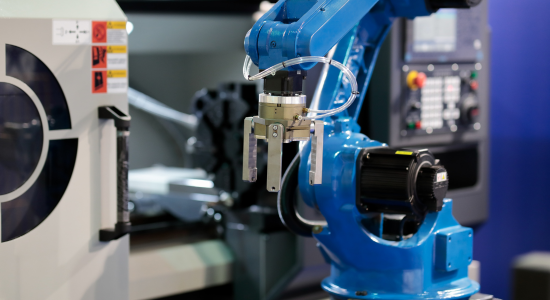

Processing capability

Processing capability of Precision Metal Processing includes advanced techniques for metal bending, welding, and stamping, utilizing state-of-the-art equipment to deliver highly accurate and reliable components. We work with a wide range of materials, such as stainless steel, aluminum, and other alloys, ensuring optimal performance and durability. Our capabilities extend to custom fabrication, surface finishing, and heat treatments, allowing us to provide solutions that meet the precise specifications of each project.

Additional processes

Additional processes of Precision Metal Processing include a variety of specialized techniques designed to enhance the functionality and quality of the parts. These include advanced surface treatments such as anodizing, powder coating, and electroplating, which improve corrosion resistance and aesthetic finish. We also offer heat treatments to achieve desired mechanical properties like hardness and strength.