Product Description

The cable wire harness for heavy cars is designed to manage and distribute power to various electrical systems in large vehicles. It includes durable wires, connectors, and terminals that ensure reliable performance under demanding conditions. This harness supports heavy-duty applications like engine control, lighting, HVAC, and power distribution. Built to withstand vibrations, high temperatures, and moisture, it offers long-lasting durability. Easy to install and configure, it minimizes wiring errors and improves vehicle safety. Compatible with various heavy vehicle models, it ensures optimal electrical efficiency and protection against damage.

Product parameters

| List | Details |

|---|---|

| Brand Name | cable wire harness for heavy car |

| Insulation Material | PVC |

| Application | Automotive, industrial |

| Conductor Material | Copper |

| Model Number | Twisted Pair |

| Type | LOW VOLTAGE |

| Standard | IEC 61076-2-101 |

| Insulation resistance | 10 M OHM |

Custom Process

1. send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

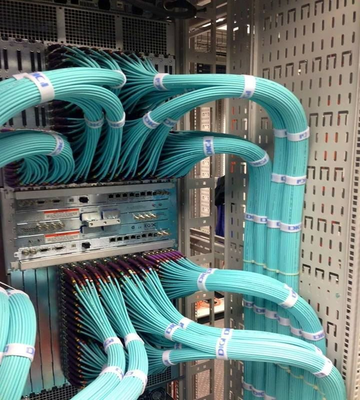

Process Type

Machining part wiring

involves creating electrical connections in a mechanical component. It starts with designing the layout of wiring paths, ensuring proper insulation and clearance. The wiring is then carefully routed through the part, with attention to securing and protecting it from damage. Connections are made using terminals or soldering, followed by testing for functionality. Finally, the part undergoes quality checks to verify electrical performance and safety standards.

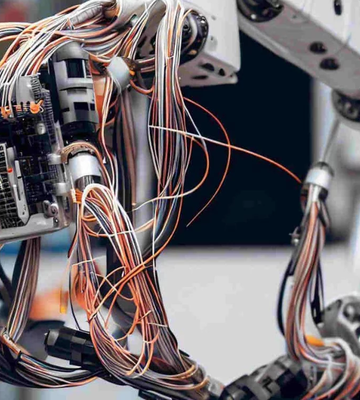

Robot part wiring

begins with designing the wiring schematic based on the robot’s components and functions. Wires are routed through the robot’s structure, ensuring minimal interference with movement. Each connection is securely terminated with connectors or soldering. The wiring is then insulated and protected from mechanical stress, heat, and environmental factors. Finally, all electrical systems are tested for proper functionality and safety compliance.

Electrical part wiring

starts with planning the circuit design and determining wire specifications. Wires are cut, stripped, and routed to connect the components as per the design. Connections are made securely using terminals, connectors, or soldering, ensuring proper insulation. The wiring is organized to prevent interference and potential damage. Finally, the electrical system is tested for continuity, functionality, and safety compliance.

Material

Copper

Nickel

Aluminum

Processing capability

The processing capability of a cable wire harness for heavy cars is crucial for managing the high electrical demands of large vehicles. It efficiently distributes power to essential systems such as engine control, lighting, air conditioning, and safety features. Designed to handle high voltage and current, the harness ensures stable operation of the vehicle’s electrical components, including sensors, motors, and communication systems.

The harness is built with advanced insulation materials to protect against extreme temperatures, moisture, and vibrations, which are common in heavy vehicles. It ensures reliable signal transmission, preventing electrical interference that could disrupt critical systems. Additionally, the harness features high-quality connectors and terminals that provide secure connections, reducing the risk of faults and improving overall performance.

Additional processes

Its modular design allows for flexible customization based on vehicle specifications, making it compatible with various heavy car models. The robust construction of the wire harness ensures longevity, reducing maintenance needs and minimizing the chances of system failures. With its processing capability, the harness enables seamless integration of modern technologies such as telematics, advanced braking systems, and powertrain management.