คำอธิบายผลิตภัณฑ์

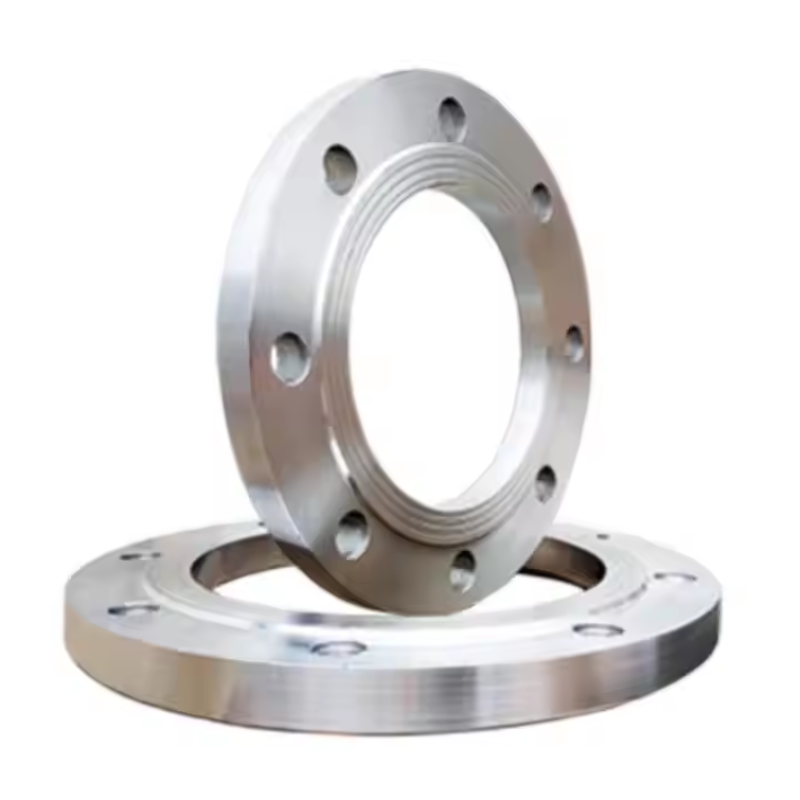

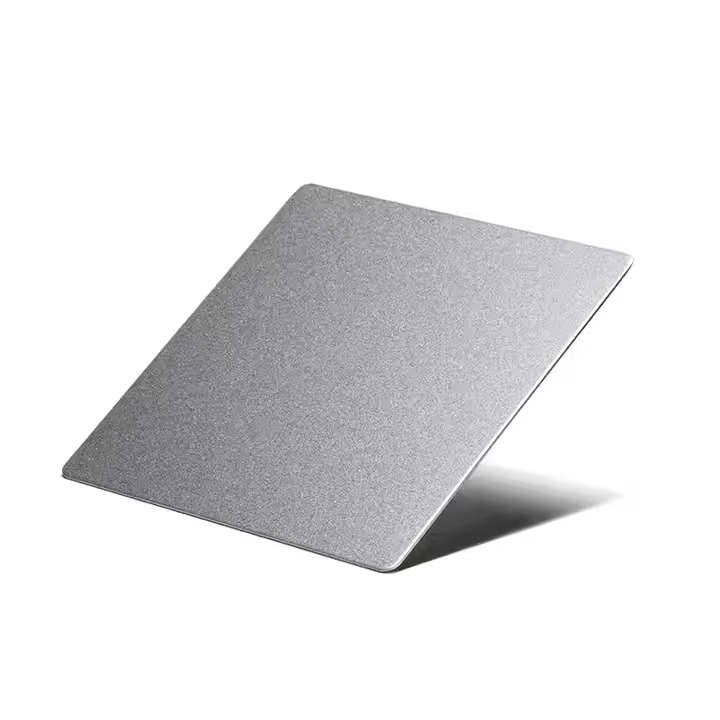

ชิ้นส่วนตีขึ้นรูปที่แม่นยำเป็นชิ้นส่วนที่มีความแข็งแรงสูง ซึ่งผลิตขึ้นผ่านกระบวนการตีขึ้นรูปที่แม่นยำเพื่อประสิทธิภาพที่ดีที่สุด ชิ้นส่วนเหล่านี้ทำจากโลหะคุณภาพสูงเพื่อให้มั่นใจในความทนทานและความน่าเชื่อถือในการใช้งานที่ต้องการความทนทานสูง เหมาะสำหรับอุตสาหกรรมต่างๆ เช่น ยานยนต์ อากาศยาน และเครื่องจักร พวกมันมีความทนทานสูงและต้านทานการสึกหรอได้ดี กระบวนการตีขึ้นรูปช่วยให้ได้ขนาดที่แม่นยำและคุณสมบัติของวัสดุที่ดีขึ้น ด้วยการควบคุมคุณภาพที่สม่ำเสมอ ชิ้นส่วนเหล่านี้จึงตรงตามมาตรฐานอุตสาหกรรมที่เข้มงวด การออกแบบที่เบาแต่แข็งแกร่งช่วยเพิ่มประสิทธิภาพโดยรวมของระบบและยืดอายุการใช้งาน.

พารามิเตอร์ผลิตภัณฑ์

| รายการ | รายละเอียด |

|---|---|

| ชื่อผลิตภัณฑ์ | ชิ้นส่วนตีขึ้นรูปที่แม่นยำ |

| วัสดุ | โลหะผสมเหล็ก |

| การใช้งาน | ชิ้นส่วนเครื่องจักร |

| การบำบัดพื้นผิว | ขัดเงา |

| กระบวนการ | การตีขึ้นรูป + การแมชีนิ่ง (ถ้าจำเป็น) + การบำบัดพื้นผิว |

| บริการ | OEM ODM ที่กำหนดเอง |

| ความคลาดเคลื่อน | ตามคำขอแบบของลูกค้า |

| การควบคุมคุณภาพ | การตรวจสอบที่เข้มงวด 100% |

กระบวนการที่กำหนดเอง

1. ส่งคำถามหรือการสอบถาม

2. ส่งแบบหรือ Drawing

3. ใบเสนอราคา

4. การยืนยันจากลูกค้า

5. สั่งซื้อและชำระเงิน

6. เริ่มทำการผลิต

7. ทดสอบก่อนบรรจุภัณฑ์

8. การจัดส่งและการยืนยัน

ประเภทกระบวนการ

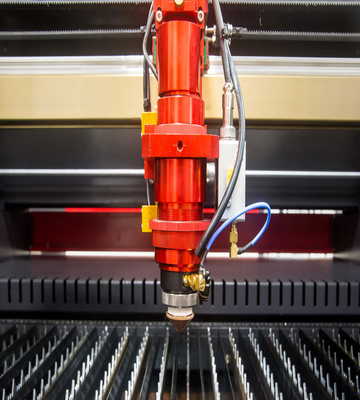

การตัดเลเซอร์

การกัดและการเจาะ

การกลึง

วัสดุ

อลูมิเนียม

ทองเหลือง

ทองแดง

การควบคุมคุณภาพ

กระบวนการควบคุมคุณภาพ (QC) สำหรับชิ้นส่วนตีขึ้นรูปที่แม่นยำประกอบด้วยการตรวจสอบวัสดุอย่างละเอียดเพื่อให้มั่นใจว่าเป็นไปตามข้อกำหนด ความแม่นยำของขนาดจะได้รับการตรวจสอบด้วยอุปกรณ์วัดที่ทันสมัย การทดสอบความแข็งแรงและความทนทานจะทำผ่านการทดสอบการดึงและความแข็ง คุณภาพผิวจะได้รับการตรวจสอบเพื่อหาข้อบกพร่องหรือความผิดปกติ ชิ้นส่วนจะได้รับการบำบัดด้วยความร้อนเพื่อเพิ่มคุณสมบัติทางกลและประสิทธิภาพ การตรวจสอบสุดท้ายจะรับประกันว่าชิ้นส่วนแต่ละชิ้นตรงตามมาตรฐานอุตสาหกรรมที่เข้มงวดก่อนการบรรจุและการจัดส่ง.

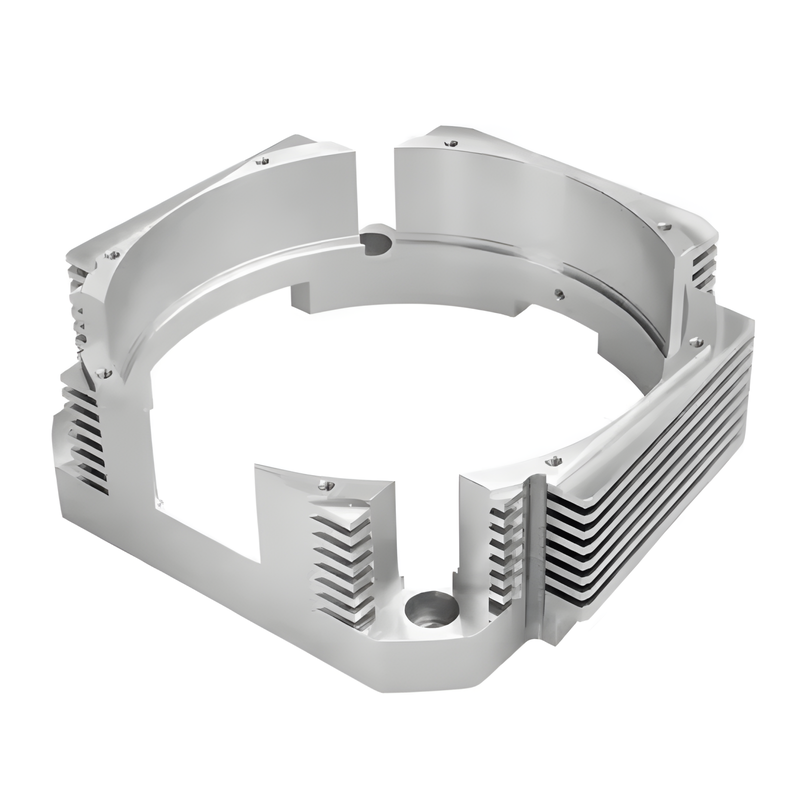

ความสามารถในการประมวลผล

ความสามารถในการประมวลผลของชิ้นส่วนตีขึ้นรูปที่แม่นยำนั้นเกี่ยวข้องกับเทคนิคการตีขึ้นรูปขั้นสูงเพื่อการขึ้นรูปที่แม่นยำและการปรับปรุงวัสดุ เครื่องตีขึ้นรูปที่อุณหภูมิสูงช่วยเพิ่มความแข็งแรงและความทนทาน เครื่อง CNC ช่วยให้ได้ขนาดที่แม่นยำและพื้นผิวที่เรียบเนียน กระบวนการบำบัดด้วยความร้อนจะช่วยปรับปรุงความแข็งและความทนทานของวัสดุ การใช้หุ่นยนต์อัตโนมัติช่วยให้การผลิตมีความสม่ำเสมอและมีประสิทธิภาพสูง กระบวนการทั้งหมดช่วยให้สามารถผลิตในปริมาณมากได้โดยยังคงรักษามาตรฐานคุณภาพที่ยอดเยี่ยม.