Product Description

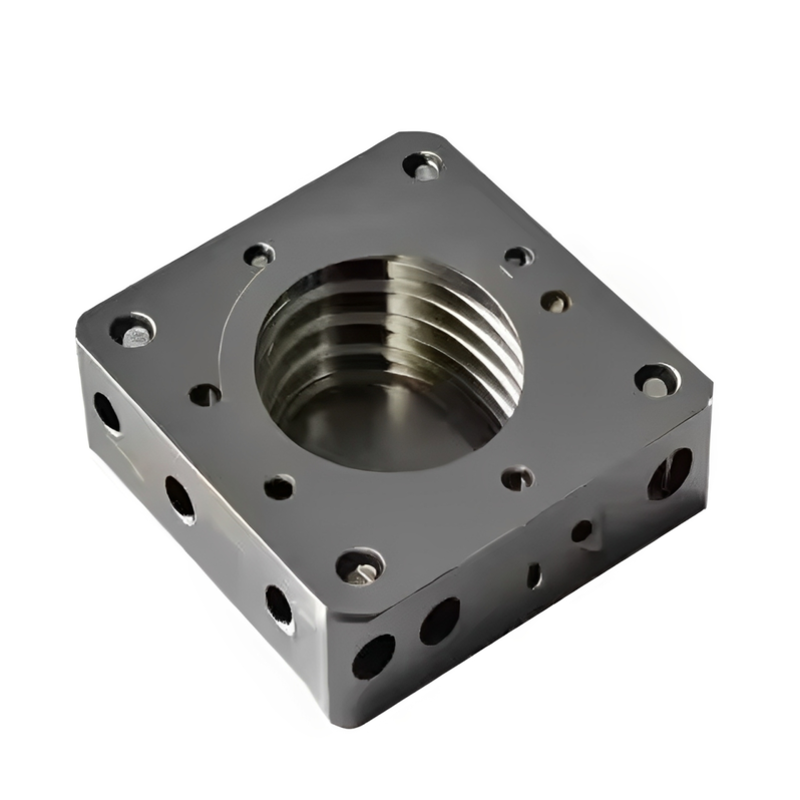

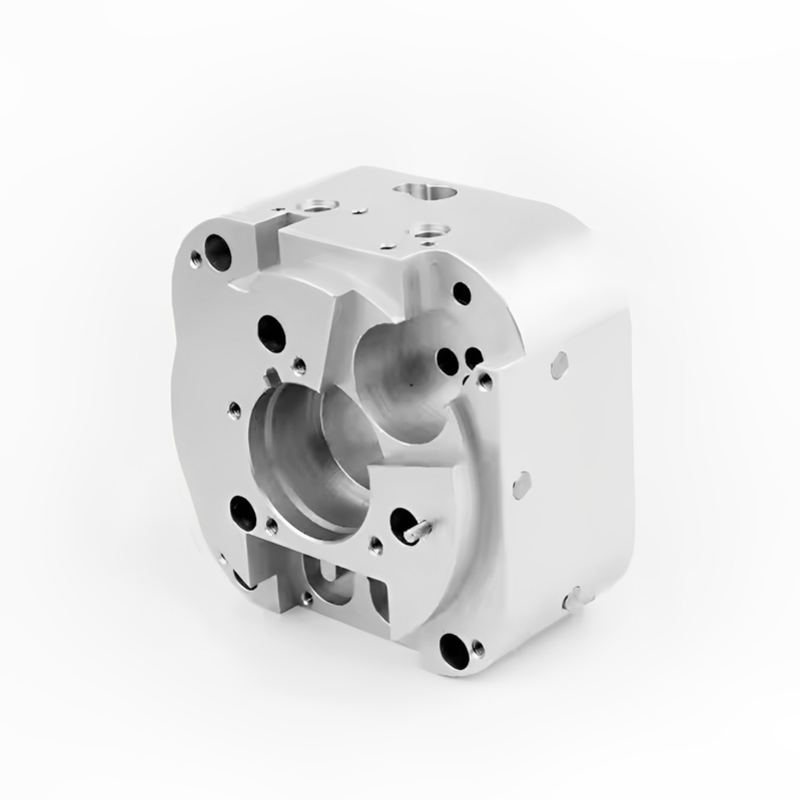

Custom CNC Titanium parts manufacturing service with modern technology and high precision. Suitable for jobs that require high quality and durability, our service is designed to meet the demanding specifications of industries such as aerospace, medical, automotive, and defense.

Product parameters

| Product Name | Custom Titanium CNC Machining Parts Service |

| Main Process | OEM Precision CNC Machined Brass Hot Forging Valve Fittings Custom Brass Forgings Machining Parts CNC Machining PartHot Forging, Cold Forging, CNC Machining |

| Material | Carbon Steel, Stainless Steel, Aluminum Alloy Or according to customer requirements |

| Forging Weight Range | 10gram - 200kgs |

| Surface Finish | Pickling, Passivation, Sand-blasting, Shot-blasting, Electro-polishing, Buffing, Mirror-polishing, Zinc/Chrome Plating, Anodizing,Powder Coating,Electrophoretic painting etc. |

| Machining Process | CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling/ Tapping/ Broaching/Reaming |

| Machining Tolerance | 0.01mm-0.05mm |

| Heat Treatment | Solution, Annealing, Quenching, Tempering, Aging, etc. |

| Special Treatment | Hardening, Vacuum Impregnation, etc. |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Automotive Mounts or Housings

Appliance Components

Storage Rack Components

Material

Aluminum Alloy

Stainless Steel

Quality Control

Quality control in our Custom Titanium CNC Machining Parts Service is a top priority throughout the entire production process. From the selection of high-grade titanium material to the final inspection, we maintain strict standards to ensure each part meets the highest levels of precision and performance. Our advanced CNC machines are calibrated to produce parts with tight tolerances, and each component undergoes thorough testing for dimensional accuracy, surface finish, and functionality.

Processing capability

Our Custom Titanium CNC Machining Parts Service offers exceptional processing capabilities, enabling us to produce complex and high-precision titanium components. Utilizing state-of-the-art CNC machines, we handle a variety of titanium grades and sizes, ensuring the efficient production of parts with intricate geometries and tight tolerances. Our multi-axis machining technology allows for the creation of highly detailed and accurate components, while our experienced team optimizes cutting parameters to achieve the best results in both speed and quality.

Additional processes

Our Custom Titanium CNC Machining Parts Service offers a range of additional processes to further enhance the functionality and durability of your titanium components. Beyond CNC machining, we provide heat treatment options to improve material strength and hardness, as well as surface treatments such as anodizing, polishing, and coating to enhance corrosion resistance and aesthetic quality. We also offer precision grinding, tapping, and drilling for added accuracy and to meet complex design requirements.