Product Description

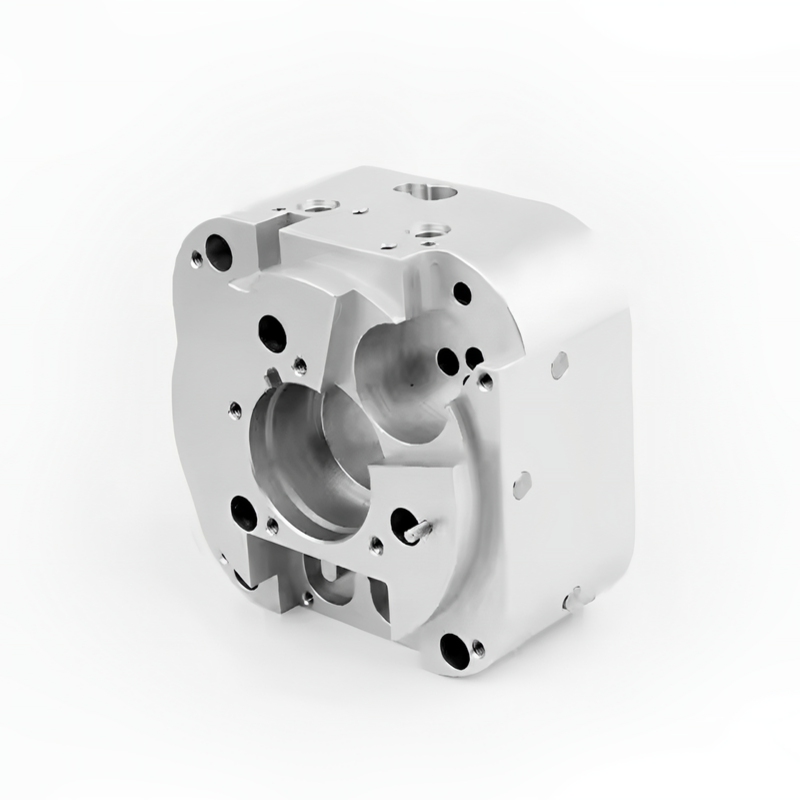

Precision forging solutions support the production of high-quality, strong, durable metal parts, suitable for industries that require high precision and efficiency. By utilizing advanced forging techniques, these solutions ensure the creation of components with superior material properties, such as enhanced strength, resistance to wear, and long-term durability.

Product parameters

| Item name | Precision Forging Solutions |

| Size | As per approval product drawings |

| DRW Format | DWG,PDF,IGS,STEP,SLDPRT,SLDDRW,PRT,DRW,DXF,X_T,etc... |

| Weight | 0.1-200kg |

| Material | Differernt types of steel,Carbon steel,Stainless steel,Alloy Steel,Aluminum alloy,copper alloy,titanium alloy,tungsten molybdenum alloy and other non-ferrous matals. |

| Surface treatment | Self color,Polishing,Painting,Powder coating,Electrophoretic coating,Anodizing,Nickel plating,Zinc planting,Hot dip galvanizing etc... |

| Quality Control | 1.Raw materials test,include chemical composition and size |

| 2.Random inspection during production | |

| 3.Final products size test,with measurement tools,special gauges and coordinate insteument if needed | |

| 4.Final products strenght and hardness test,to guarantee the machanical property | |

| 5.Assembly and function test,with special testing gauges | |

| 6.Packing test |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

Robotic Equipment

Electric Vehicles

Industrial Machinery

Material

Aluminum Alloy

Stainless Steel

Copper

Quality Control

Quality control of Precision Forging Solutions ensures that every component meets the highest standards of strength, accuracy, and reliability. From the selection of raw materials to the final inspection, every stage of the forging process is closely monitored to guarantee consistency and superior performance. Rigorous testing methods, including dimensional checks, hardness testing, and material analysis, are conducted to verify that each part meets the required tolerances and specifications.

Processing capability

The processing capability of Precision Forging Solutions involves advanced techniques that ensure the production of highly accurate, durable metal components. Using state-of-the-art forging equipment, we are able to produce parts with complex geometries and tight tolerances, making them suitable for a variety of industries, including automotive, aerospace, and industrial machinery. The process is optimized for efficiency and precision, allowing for consistent results across high-volume production runs.

Additional processes

Additional processes for Precision Forging Solutions include heat treatment, surface finishing, and post-forging machining to enhance the strength, durability, and performance of the components. Heat treatment processes such as annealing, quenching, and tempering are applied to optimize hardness, improve resistance to wear, and enhance fatigue strength. Surface finishing techniques like polishing, coating, or plating are used to provide a smooth, corrosion-resistant finish that meets industry standards.