Product Description

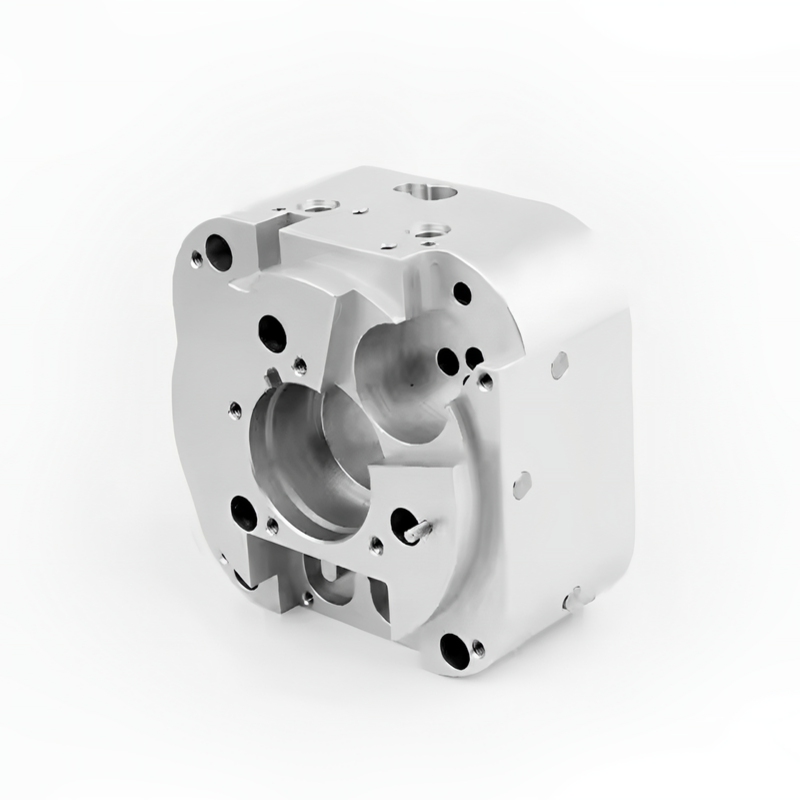

High-quality Aluminum Brass Ball Tie Rod designed for precision machinery applications. Manufactured using advanced techniques to ensure exceptional strength, durability, and resistance to pressure, making it an ideal solution for demanding environments. Its superior material composition combines the lightweight properties of aluminum with the strength and corrosion resistance of brass, offering optimal performance in machinery parts that require high precision and reliability.

Product parameters

| Model Number | OEM |

| Product Name | Aluminum Brass Ball Tie Rod |

| Quotation | According to your drawing |

| Drawing Formats | 2D (PDF/CAD) and 3D (STP / STEP) |

| Materials | Iron, Stainless Steel, Steel, Brass, etc. |

| Surface Finish | Galvanized, Anodizing, Powder Coated, Chrome Plating, etc. |

| Application | Automotive, Medical, Telecom, Construction, Machine, etc. |

| Thickness | 0.5mm ~ 16.0mm |

| Type | Sheet Metal, Etching, Chemical Treatment, Laser Cut, etc. |

| Service | Custom Sheet Metal Fabrication Services |

Custom Process

1.send inquiries

2.drawings or samples

3. Quotation

4.customer confirmation

5. places order and pays

6.Mass production

7.Test before packaging

8.Shipping & confirmation

Process Type

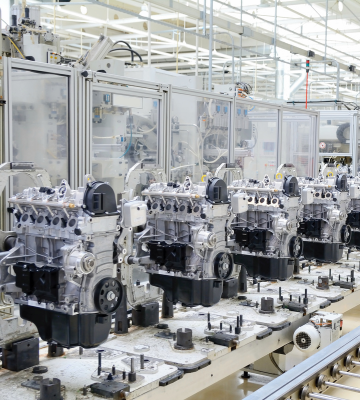

Automotive Manufacturing Machines

Aerospace Manufacturing Machines

Wind Turbine Manufacturing Machines

Material

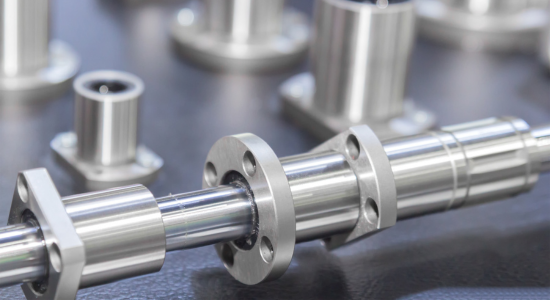

Aluminum Alloy

Stainless Steel

Copper

Quality Control

In quality control of Aluminum Brass Ball Tie Rod, we pay attention to every step of the manufacturing process to ensure maximum durability and performance. Every part is thoroughly inspected, from quality material selection to precise manufacturing processes. Our team performs pressure resistance, corrosion resistance, and surface finishing tests to ensure that the manufactured parts are perfect and can be used in challenging environments. The inspection process also includes dimensional measurements with high-precision instruments.

Processing capability

Our production of Aluminum Brass Ball Tie Rod has a wide range of precision processing capabilities, using advanced technology to cut and form materials to produce parts of sizes and shapes that meet customer requirements. We can support high-volume or low-volume production, including customizing sizes and properties such as drilling, grinding, and plating to increase corrosion resistance. With state-of-the-art tools and techniques, our production can produce high-quality parts that meet the requirements of precision and high-efficiency machinery.

Additional processes

For Aluminum Brass Ball Tie Rod, we have various additional processes that enhance the quality and efficiency of the parts to suit various applications, such as polishing to produce a smooth and scratch-free surface, plating to increase corrosion resistance, and painting or coating with various processes such as chrome plating, powder coating or anodizing to increase the durability and beauty of the product. In addition, drilling, cutting or engraving can be done according to customer requirements to produce parts with precision and meet the requirements for use in challenging environments.