产品描述

螺栓预紧力传感器采用筒式结构,结构小巧,性能稳定可靠,安装使用方便。适用于螺栓预紧力、试验机等工业自动化测量控制系统。

产品规格

规格 | 输出类型 | 精度 | 测量范围 | 灵敏度 | 重复性 | 工作温度 | 外壳材质 | 线性范围 |

0~120KN | 模拟电压 | ±0.05% | 120KN | 2.0mV/V | ≤±0.05%F.S | -20℃-+60℃ | 合金钢/不锈钢 | ≤±0.3%F.S |

0~180KN | 模拟电压 | ±0.05% | 180KN | 2.0mV/V | ≤±0.05%F.S | -20℃-+60℃ | 合金钢/不锈钢 | ≤±0.3%F.S |

0~210KN | 模拟电压 | ±0.05% | 210KN | 2.0mV/V | ≤±0.05%F.S | -20℃-+60℃ | 合金钢/不锈钢 | ≤±0.3%F.S |

0~240KN | 模拟电压 | ±0.05% | 240KN | 2.0mV/V | ≤±0.05%F.S | -20℃-+60℃ | 合金钢/不锈钢 | ≤±0.3%F.S |

0~320KN | 模拟电压 | ±0.05% | 320KN | 2.0mV/V | ≤±0.05%F.S | -20℃-+60℃ | 合金钢/不锈钢 | ≤±0.3%F.S |

0~400KN | 模拟电压 | ±0.05% | 400KN | 2.0mV/V | ≤±0.05%F.S | -20℃-+60℃ | 合金钢/不锈钢 | ≤±0.3%F.S |

0~500KN | 模拟电压 | ±0.05% | 500KN | 2.0mV/V | ≤±0.05%F.S | -20℃-+60℃ | 合金钢/不锈钢 | ≤±0.3%F.S |

0~600KN | 模拟电压 | ±0.05% | 600KN | 2.0mV/V | ≤±0.05%F.S | -20℃-+60℃ | 合金钢/不锈钢 | ≤±0.3%F.S |

产品参数

额定载荷 | 120KN~600KN | 输入电阻 | 750±30Ω |

灵敏度 | 1.5±0.05mV/V | 输出电阻 | 700±5Ω |

非线性 | ±0.3~±0.5%F·S | 工作温度范围 | -20~+70°C |

滞后误差 | ±0.3%F·S | 安全过载 | 150%F·S |

重复性误差 | ±0.1%F·S | 绝缘电阻 | ≥2000MΩ |

蠕 变 | ±0.1%F·S | 推荐激励电压 | 5V~12V |

零点温度系数 | ±0.1%F·S/10°C | 防护等级 | IP65 |

灵敏度温度系数 | ±0.1%F·S/10°C | 材质 | 合金钢、不锈钢 |

线缆 | ф5x3m |

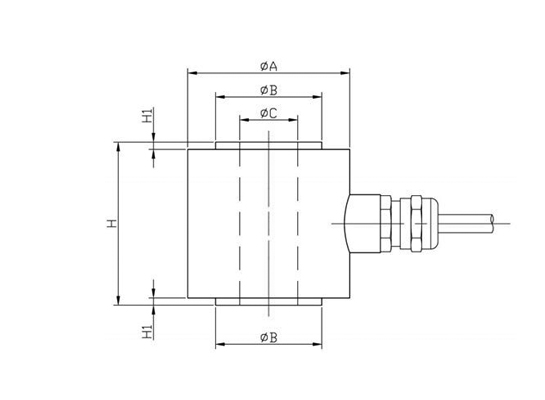

量程 | øA | øB | øC | H | H1 |

120KN | ø45 | ø29.5 | ø16.1 | 45 | 2 |

180KN | ø51 | ø36.5 | ø20.1 | 55 | 2 |

210KN | ø54 | ø39.5 | ø22.1 | 58 | 2 |

240KN | ø57 | ø42.5 | ø24.1 | 65 | 2 |

320KN | ø64 | ø48.5 | ø27.1 | 72 | 2 |

400KN | ø69 | ø54.5 | ø30.1 | 76 | 2 |

500KN | ø80 | ø60.5 | ø33.1 | 84 | 2 |

600KN | ø88 | ø66.5 | ø36.1 | 90 | 2 |

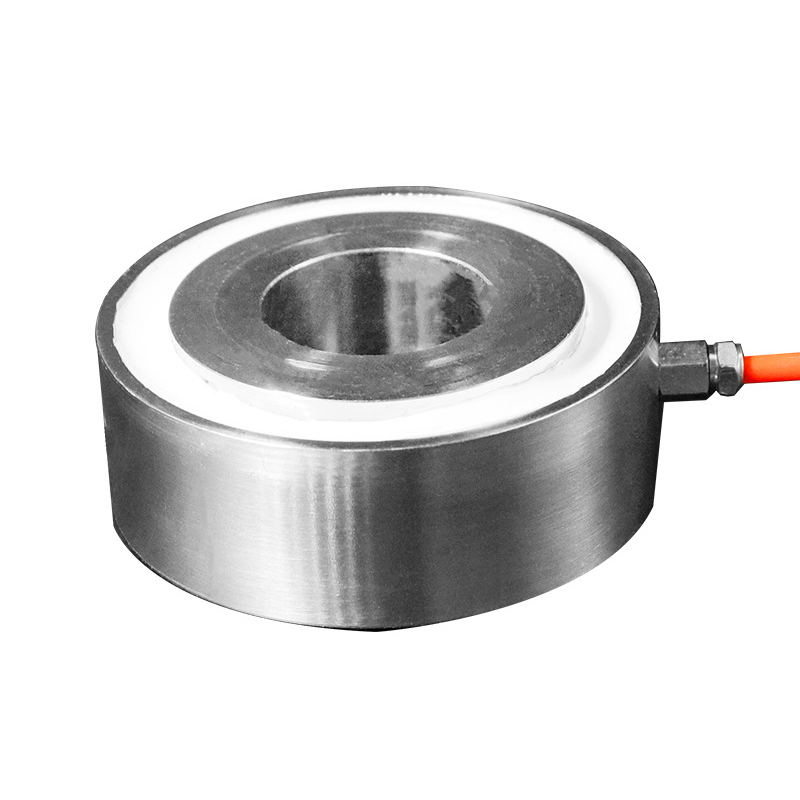

产品展示

采用筒式结构

传感器采用筒式结构,结构小巧适用于螺栓预紧力、试验机等工业自动化测量控制系统

精度高 性能稳定

结构小巧,综合精度高。适用于螺栓预紧力、试验机等工业自动化测量控制系统

抗偏载,安装方便

抗偏载、精度高、强度好、安装方便,信号稳定,抗干扰强

尺寸和接口

应用案例

多种工况

全面兼容

螺栓检测机 x 试验机 x 自动化设备

适用于螺栓预紧力、试验机等工业自动化测量控制系统。

服务

1. 隆旅为客户提供安装调试远程服务,以及其他技术咨询,必要时技术人员可上门提供技术培训。客户如有技术上疑问,技术人员将在24个小时内给出回复。

2. 隆旅产品严格按照ISO9001国际质量体系设计生产,传感器产品质保1年.仪表类产品质保3年,7天退换货,终身维修。(人为损坏不在质保范围,定制产品无质量问题不退不换。)

3. 因质量问题造成的退换货,隆旅将承担退换货运费。非质量问题退换货费用将由客户承担。注:质量问题是指功能,尺寸、指标、安装方式等定制参数未按照客户提出的要求定制,功能不符,尺寸误差,精度不准(误差范围内除外)。定制产品需双方确认图纸后加工生产,如产品不符合客户要求需在二周内提出书面异议,客户未按规定期限提出异议视为验收合格。如在期限内提出异议,双方确认后确属产品质量问题或未按双方确认后的要求生产,可调换或退款。如无质量问题,且发货型号与合同签订型号完整无误,则不提供退换货服务。

4. 返厂维修的产品将在3个工作日内出具检测结果,7个工作日内完成维修。